Ozone reaction system

A reaction system, ozone technology, applied in the direction of oxidation water/sewage treatment, water/sewage multi-stage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve secondary pollution and other problems, and achieve the goal of avoiding secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

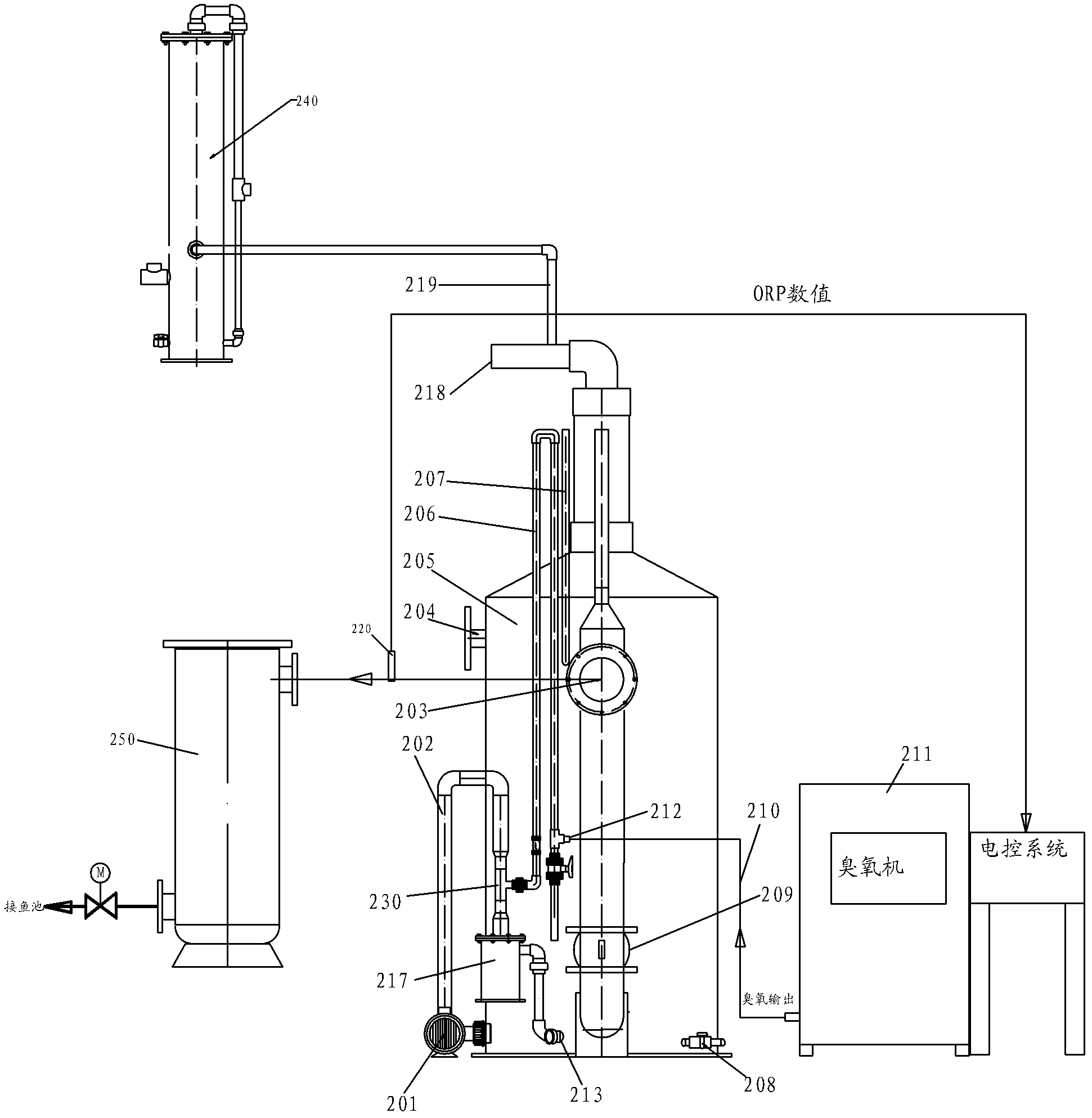

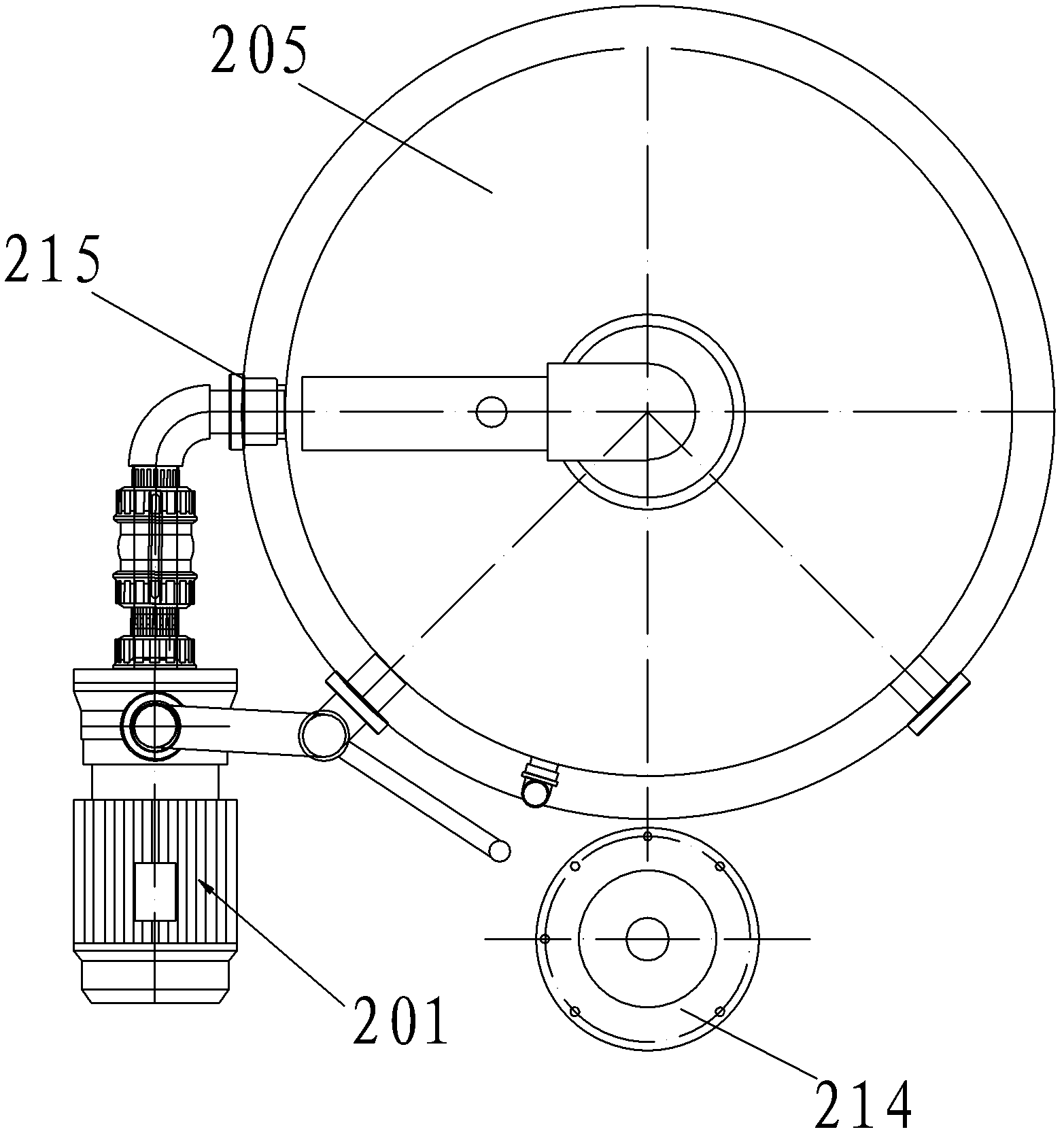

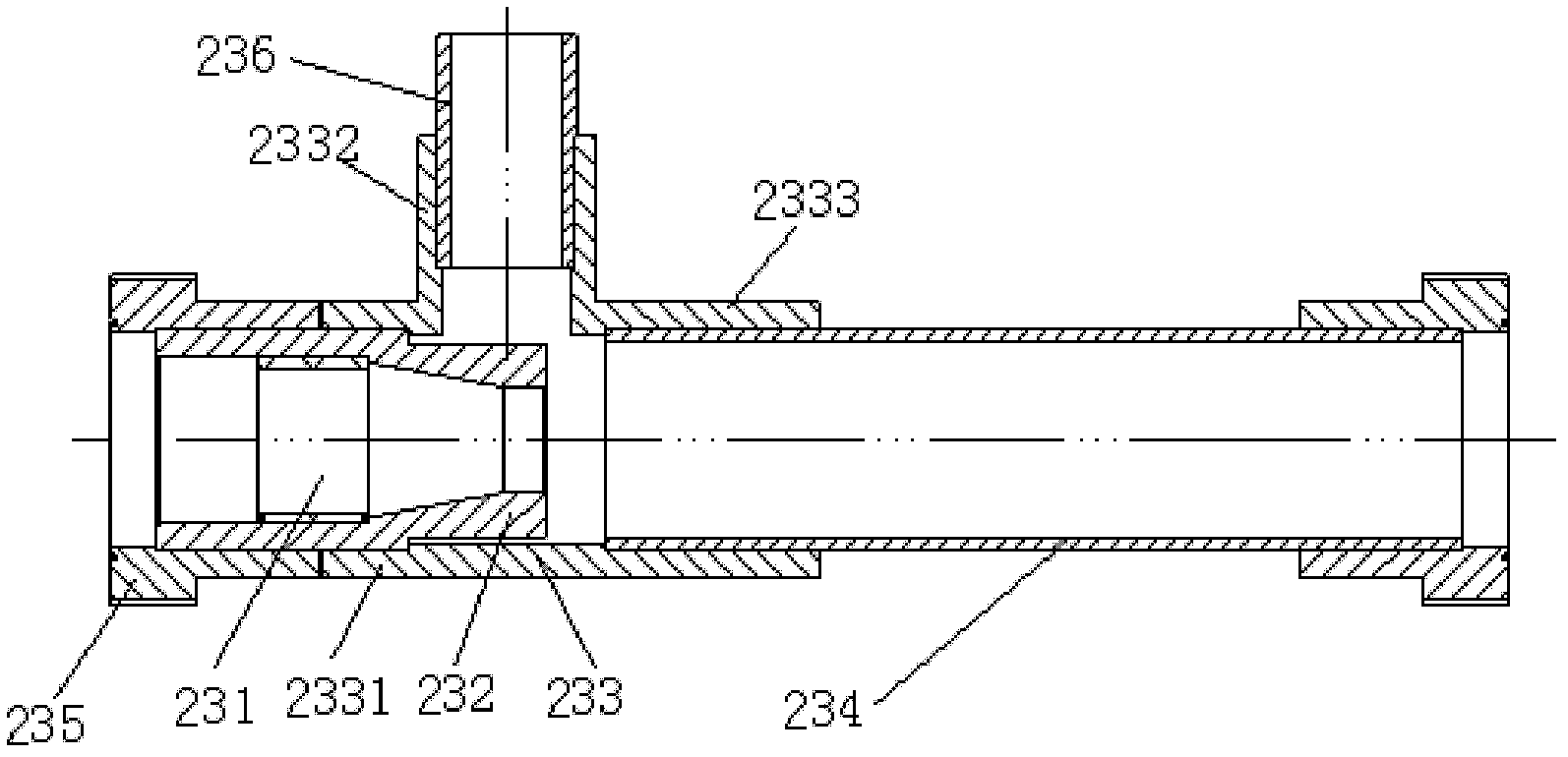

[0022] Such as figure 1 As shown, the ozone reaction system of the present invention comprises an ozone reaction tower and an ozone machine 211, and the ozone reaction tower includes a mixing chamber 205, a jet pump 201, a main air inlet pipe 206 and a drain pipe 214, and the mixing chamber 205 can be a hollow cylindrical barrel body, the barrel body is provided with a water inlet 204, a drain pipe installation port, a circulating water outlet 215 and a circulating water inlet 213, the water inlet of the jet pump 201 communicates with the circulating water outlet 215, and the water outlet of the jet pump 201 passes through the internal circulation The pipeline 202 communicates with the circulating water inlet 213. An air-water jet mixer 230 is arranged on the internal circulation pipeline 202. The nozzle of the air-water jet mixer 230 is dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com