Solid Phase Synthesis Process of Degarelix

A technology of solid-phase synthesis and degarelix, which is applied in the field of solid-phase synthesis of degarelix, can solve the problems of increasing the possibility of isomerization, complicated operation, and easy occurrence of isomerization, etc., so as to reduce the possibility of The effect of high stability, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

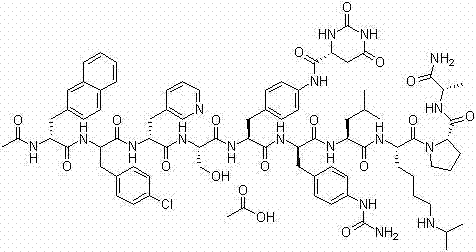

Image

Examples

Embodiment 1

[0040] Embodiment 1: the synthesis of Fmoc-D-Ala-Sieber resin

[0041]Put Sieber resin (10mmol, substitution degree 0.3mmol / g) into the solid-phase reaction column, wash it twice with DMF, add 500ml DMF to swell for 30min. Add 500ml 20% DBLK for deprotection for 10min, then add 500ml 20% DBLK for deprotection for 15min, and wash with DMF for 6 times. Dissolve 9.34g Fmoc-D-Ala-OH and 4.26g HOBt in 60ml DMF, ice bath for 10 minutes, add 4.9ml DIC, pre-activate for 2~5min, add the activated solution to the solid phase reaction column, stir for 2h, ninhydrin The test was negative. Drained, washed 6 times with DMF, washed 3 times with DCM, shrunk MeOH three times (5min, 5min and 10min respectively), and dried to obtain Fmoc-D-Ala-Sieber resin. The degree of substitution was 0.298mmol / g.

Embodiment 2

[0042] Embodiment 2: the synthesis of Fmoc-D-Ala-Sieber resin

[0043] Put Sieber resin (10mmol, substitution degree 0.5mmol / g) into the solid-phase reaction column, wash it twice with DMF, add 500ml DMF to swell for 30min. Add 500ml 20% DBLK for deprotection for 10min, then add 500ml 20% DBLK for deprotection for 15min, and wash with DMF for 6 times. Dissolve 9.34g Fmoc-D-Ala-OH and 4.26g HOBt in 60ml DMF, ice bath for 10 minutes, add 4.9ml DIC, pre-activate for 2~5min, add the activated solution to the solid phase reaction column, stir for 2h, ninhydrin The test was negative. Drain, wash 6 times with DMF, wash 3 times with DCM, shrink MeOH three times (the time is 5min, 5min and 10min respectively), and after drying, Fmoc-D-Ala-Sieber resin is obtained, and the substitution degree is 0.495mmol / g.

Embodiment 3

[0044] Embodiment 3: the synthesis of Fmoc-D-Ala-Sieber resin

[0045] Sieber resin (10mmol, substitution degree 0.8mmol / g) was loaded into the solid-phase reaction column, washed twice with DMF, and 500ml DMF was added to swell for 30min. Add 500ml 20% DBLK for deprotection for 10min, then add 500ml 20% DBLK for deprotection for 15min, and wash with DMF for 6 times. Dissolve 9.34g Fmoc-D-Ala-OH and 4.26g HOBt in 60ml DMF, ice bath for 10 minutes, add 4.9ml DIC, pre-activate for 2~5min, add the activated solution to the solid phase reaction column, stir for 2h, ninhydrin The test was negative. Drain, wash 6 times with DMF, wash 3 times with DCM, shrink MeOH three times (5min, 5min and 10min respectively). After drying, Fmoc-D-Ala-Sieber resin is obtained, and the substitution degree is 0.799mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com