Goaf slip casting treatment method of road

A goaf and grouting technology, which is applied to mining equipment, earth square drilling, filling, etc., can solve the problems of uncommon application, difficult implementation, and long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

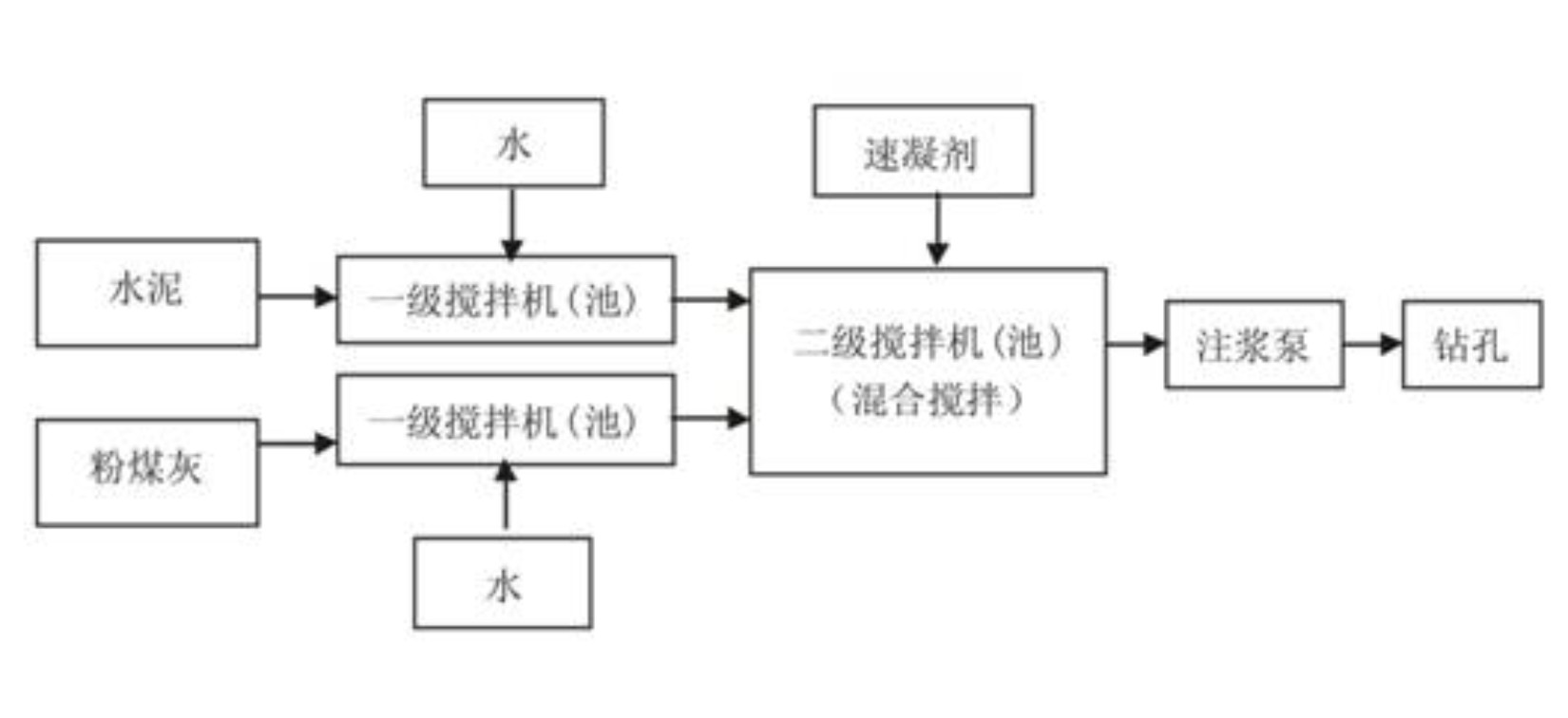

Method used

Image

Examples

Embodiment Construction

[0030] (1) fixed point

[0031] The grouting hole shall be measured and set out on the spot with theodolite and tape measure, and the principle error of the actual position of the borehole shall not exceed 0.5m. Due to the impact of the terrain, when the borehole cannot be placed in the design position, it can be adjusted according to the specific situation with the approval of the design representative and engineering supervisor.

[0032] (2) Drilling and casing

[0033] Boreholes are constructed on the surface.

[0034] ① Open the hole with a φ127mm drill bit, drill to 6m of the complete bedrock, run in a φ114mm casing or welded pipe retaining wall, and then reduce the diameter to φ91mm. Follow-up pipe drilling is used in the drilling process of Quaternary eggs and gravel layers.

[0035] ② Use a φ89mm drill bit to drill to the subsidence and caving zone in the coal seam goaf or 1m below the coal seam floor.

[0036] (3) Pouring orifice pipe

[0037] The operation of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com