Manufacturing method of silicon epitaxial wafer for MMW (millimeter wave) avalanche diode

A technology for silicon epitaxial wafers and manufacturing methods, which are applied in the directions of final product manufacturing, chemical instruments and methods, sustainable manufacturing/processing, etc., to achieve the effects of stable epitaxial layer thickness, low growth temperature, and reduced compensation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

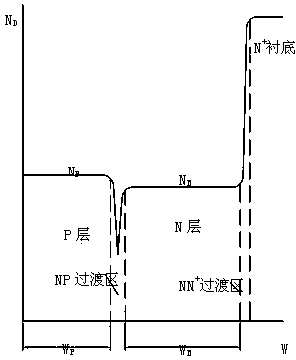

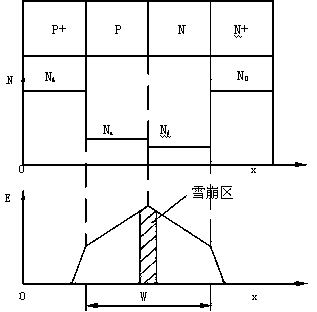

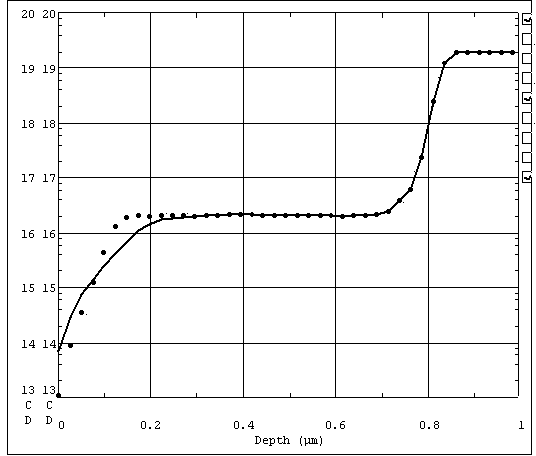

[0031] The size of the transition region directly affects the output power and conversion efficiency of the avalanche diode, the concentration of the P-type and N-type epitaxial layers directly affects the operating frequency of the avalanche diode, and the thickness of the P-type and N-type epitaxial layer directly affects the breakdown voltage of the avalanche diode. The invention has been created. The invention is a multi-layer epitaxy technology developed based on the theory of self-doping generation mechanism, suppression method and solid-state diffusion. The special requirements put forward for avalanche diodes, compared with conventional epitaxy, its technology is characterized by controlling the gas corrosion amount of HCl and encapsulating the substrate surface with a pure epitaxial layer; using lower growth temperature and lower deposition ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com