Nonaqueous electrolyte for secondary lithium ion battery

A secondary lithium battery and electrolyte technology, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as affecting battery capacity, poor low-temperature performance, and poor low-temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

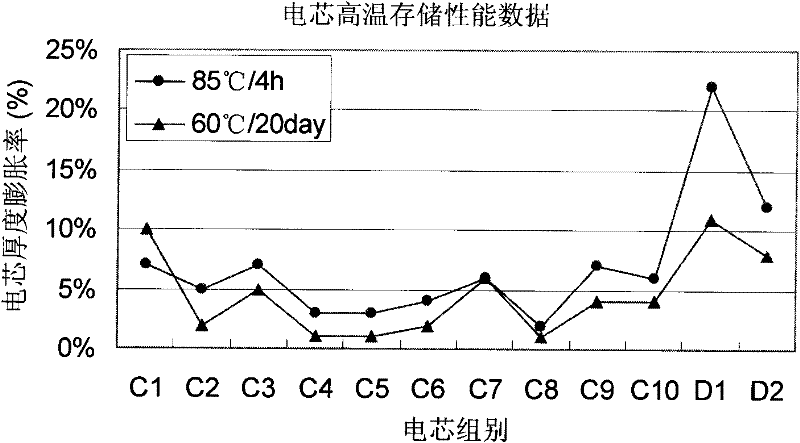

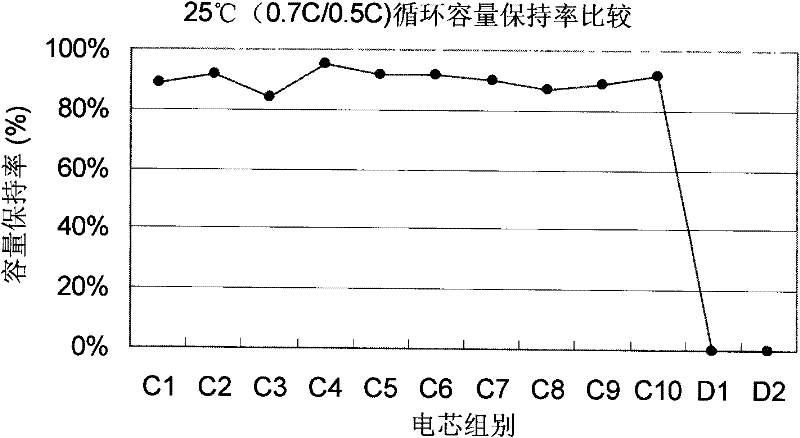

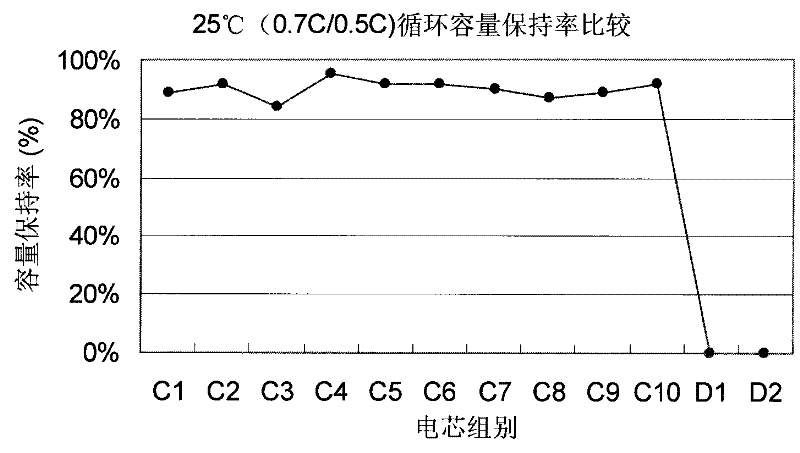

Examples

preparation example Construction

[0036] Using the same preparation as above, using a mixed solvent system of EMC, MPC (methyl propyl carbonate) and EC, the volume ratio is about 1:4:5, and 1% VC and 3% PS are added to the above organic solvent system , This electrolyte is B1. Use a mixed solvent system of DEC, EC, and PC with a volume ratio of about 4:3:3. Add 1% of VC and 3% of PS to this organic solvent system. The electrolyte is B2.

[0037] Table 2 Details of each comparative example

[0038] EC

[0039] 4. Preparation of lithium ion battery

Embodiment 1

[0041] The negative pole piece made of high graphitized high energy density graphite, the high graphitized high energy density graphite is artificial graphite, and the positive pole piece made of lithium cobalt oxide is made into a bare cell by winding. The core and outer packaging are made of aluminum-plastic composite film, which is poured into electrolyte A1 and formed into a flexible lithium-ion battery C1 with a capacity of 1450mAh. The shape of the battery can be made into any shape according to customer requirements.

Embodiment 2

[0043] Referring to Example 1, a bare cell was produced, except that when the electrolyte was poured, the A2 electrolyte was used to produce the lithium ion battery C2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com