Flavor enhancer and flavoring agent composition

一种风味增强剂、组合物的技术,应用在香料组合物领域,能够解决香料稳定性不高等问题,达到增强果实感、余香性提高、风味增强的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

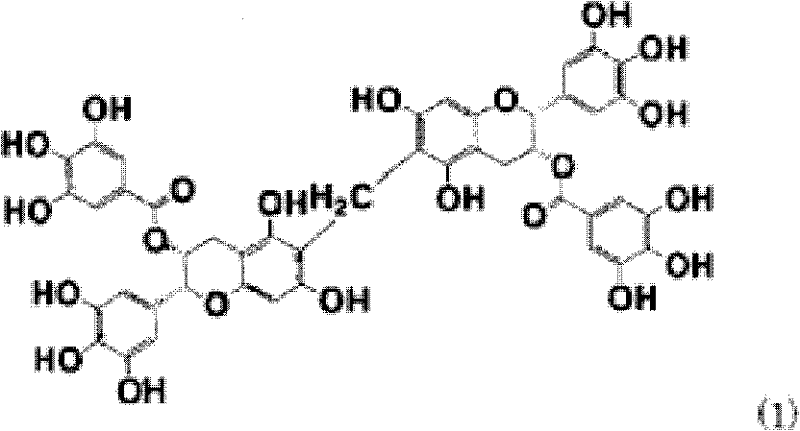

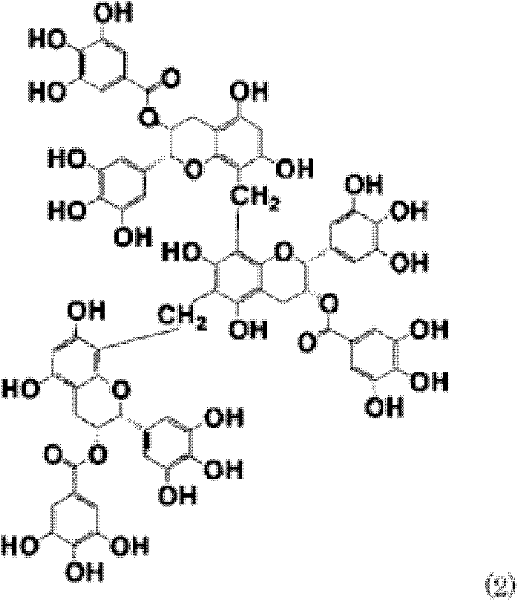

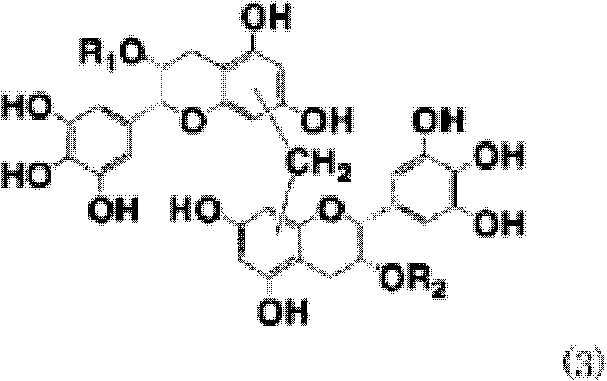

Image

Examples

manufacture example 1

[0106]

[0107]Using 7800 kg of sodium bicarbonate solution obtained by adding 0.15% by weight of sodium bicarbonate to warm water (95° C.), 600 kg of oolong tea leaves were extracted to obtain about 7000 kg of oolong tea extract. While maintaining the liquid temperature of the extract at 60 to 65° C., non-polymerized catechin and caffeine were removed by passing through 400 kg of granular activated carbon (GW-H32 / 60 manufactured by Kuraray Co., Ltd.). The passing liquid (liquid after activated carbon treatment) was concentrated under reduced pressure to obtain about 900 kg of Brix11 high-polymerized catechin-containing extract (concentrate of oolong tea extract; extract) (hereinafter referred to as extract A). Concentrations of polymerized catechins, non-polymerized catechins and caffeine in the obtained extract A were measured by HPLC under the following conditions. As a result, the concentration of polymerized catechin was 12000 ppm, the concentration of non-polymerized c...

manufacture example 2

[0123]

[0124] Using a sodium bicarbonate liquid obtained by adding 0.15% by weight of sodium bicarbonate to warm water (95° C.), extraction treatment was performed on oolong tea leaves to obtain an oolong tea extract. The extract was freeze-dried, and 8 g was used for the following preparative chromatography. The components eluting at 59.8-70 minutes were collected and freeze-dried to obtain polymerized catechin (refined product).

[0125] HPLC conditions:

[0126] · Chromatographic column: ODS-10 / 20 (50*300mm+50*100mm, manufactured by Nomura Chemical Co., Ltd.)

[0127] Mobile phase A: water: acetonitrile: trifluoroacetic acid = 900: 100: 0.5

[0128] B: water: acetonitrile: trifluoroacetic acid = 200: 800: 0.5

[0129] ·Flow rate: 60ml / min

[0130] ·Column temperature: 40℃

[0131] ・Gradient conditions: from the start of the analysis to 52 minutes later, liquid B 0%,

[0132] Liquid A 100% from 52 minutes to 52.1 minutes,

[0133] Liquid A 100% from 52.1 minutes t...

Embodiment 1

[0138] Embodiment 1: the flavor enhancing effect of polymerized catechin (extract A)

[0139] As shown in Table 1, water was added to the concentrate of the tea extract obtained in Production Example 1 (extract containing polymerized catechins, i.e. extract A) so that the content of polymerized catechins was 0 to 500 ppm (0 ~0.05% by weight). After adding 0.15% by weight of lemon fragrance there, it was sterilized at 85° C. for 10 minutes and cooled to 5° C. to obtain lemon-flavored water (pH 6.2 to 6.5, Brix 0.01 to 0.46). Sensory evaluation of the lemon flavored water was carried out by 3 professional judges. The sensory evaluation was based on the flavor enhancing effect, that is, the intensity of the lemon flavor compared to the control to which no polymerized catechin (extract A) was added. The comprehensive evaluation of the enhancement of the aroma and the enhancement of the aroma of the aftertaste (aftertaste), according to the comparison with the control, the fruit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com