Preparation method of quinoa essence with anti-wrinkle and anti-aging effects, quinoa essence and cosmetics applying quinoa essence

An anti-aging and cosmetic technology, applied in the direction of medical preparations containing active ingredients, cosmetics, cosmetic preparations, etc., can solve the problems of not being able to tap the value of quinoa well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

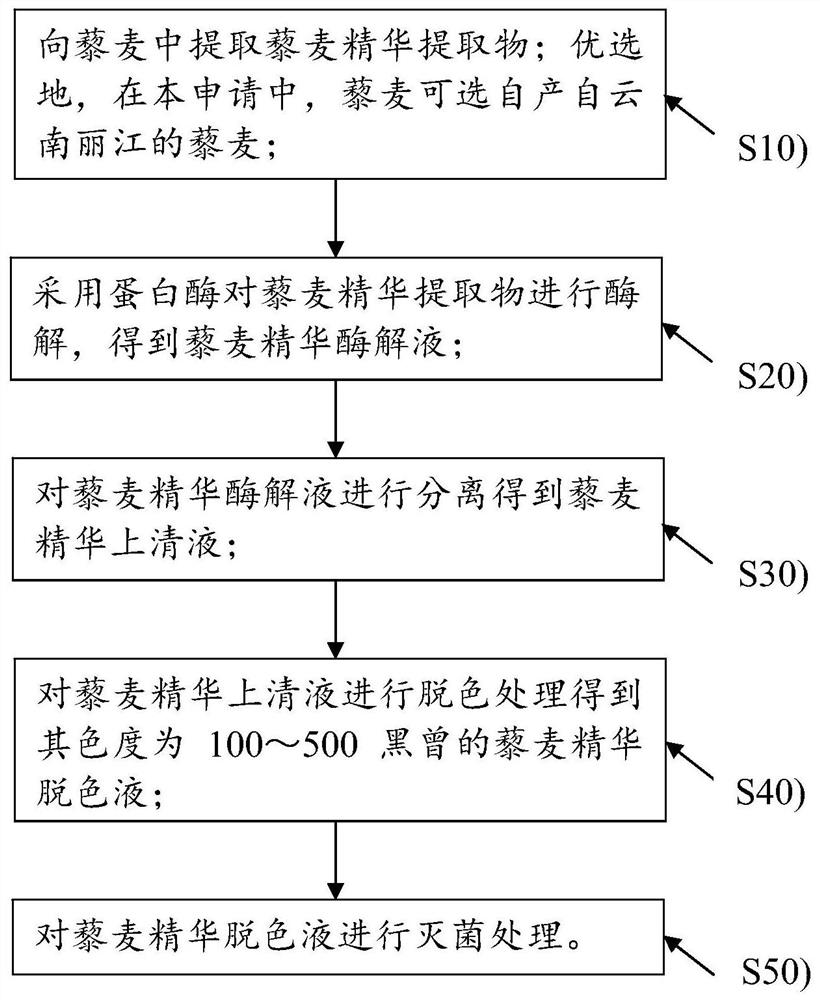

[0026] See figure 1 As shown, the embodiment of the present invention discloses a preparation method of quinoa essence with anti-wrinkle and anti-aging effects, comprising the following steps:

[0027] S10), extracting quinoa essence extract from quinoa; preferably, in this application, quinoa can be selected from quinoa produced in Lijiang, Yunnan; preferably, in this step S10), through a known process Concentrated salt method or dilute alkali method extracts quinoa essence extract in a dry state from quinoa; wherein, the specific operation process of concentrated salt method or dilute alkali method generally includes steps such as extraction, pH adjustment and sedimentation, separation, and drying.

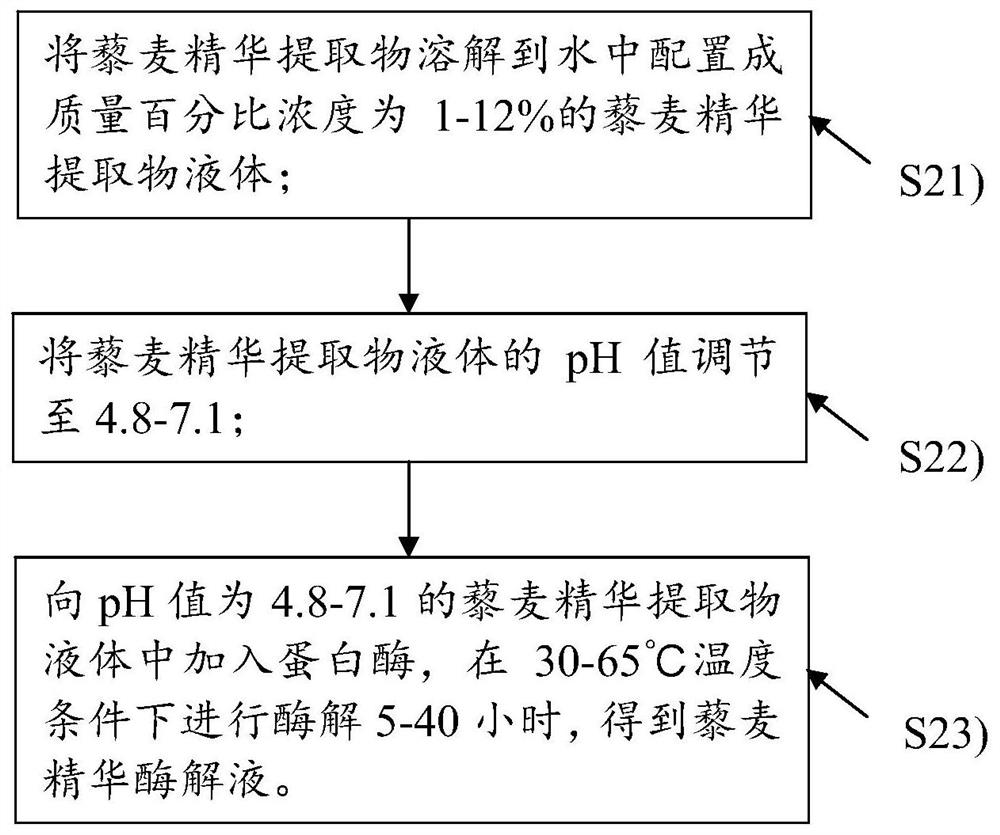

[0028] S20), using protease to enzymolyze the quinoa essence extract to obtain quinoa essence enzymatic hydrolyzate; preferably, please refer to figure 2 As shown, the enzymatic hydrolysis step of this step S20) includes as follows:

[0029] S21), dissolving the quinoa essenc...

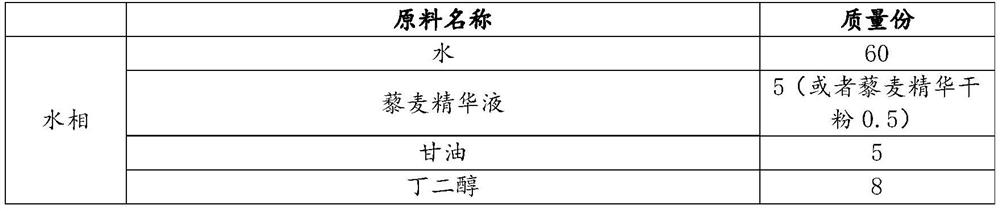

Embodiment 1

[0039] Embodiment 1: Dissolving quinoa essence extract 5kg in purified water is mixed with the quinoa essence extract liquid that mass percent concentration is 1%, and the pH of regulating quinoa essence extract liquid is 4.8, adds the quinoa essence extract The liquid mass of 0.1% papain is enzymatically hydrolyzed at 30°C for 5 hours to obtain quinoa essence enzymatic hydrolysis solution, heated to 95°C for 1.5h to inactivate the enzyme, and the molecular weight cut-off is 5000 Dal The membrane separation was carried out on the ceramic membrane of Dayton, and the permeated quinoa essence supernatant was collected.

[0040] Use hydrochloric acid to adjust the pH value of the quinoa essence supernatant to 5, heat to 45°C, decolorize through the macroporous adsorption resin, and collect the quinoa essence decolorization liquid; sterilize the quinoa essence decolorization liquid at an ultra-high temperature of 130°C for a short time Machine sterilization for 4-6 seconds to get t...

Embodiment 2

[0042] Embodiment 2: the quinoa essence extract 5kg is added pure water and is mixed with the quinoa essence extract liquid that the mass percent concentration is 8%, and the pH of regulating the quinoa essence extract liquid is 7.1, adds the quinoa essence extract liquid 3% papain by mass was used for enzymolysis at 65° C. for 40 hours to obtain quinoa essence enzymatic hydrolyzate. Heat the quinoa extract enzymatic solution to 95°C for 1.5 hours to inactivate the enzyme, use a ceramic membrane with a molecular weight cut-off of 25,000 Daltons for membrane separation, and collect the permeated quinoa extract supernatant.

[0043] Use hydrochloric acid to adjust the pH value of the quinoa essence supernatant to 6, heat to 60°C, add 1.5% activated carbon for adsorption and decolorization, and collect the quinoa essence decolorization liquid; sterilize the quinoa essence decolorization liquid at an ultra-high temperature of 150°C for a short time Machine sterilization for 4-6 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com