Pressure-swing adsorption (PSA) gas separation technology

A technology of gas separation and pressure swing adsorption, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of lower product gas yield, product gas loss, and low purity of product gas, so as to improve the utilization rate , the effect of stable purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

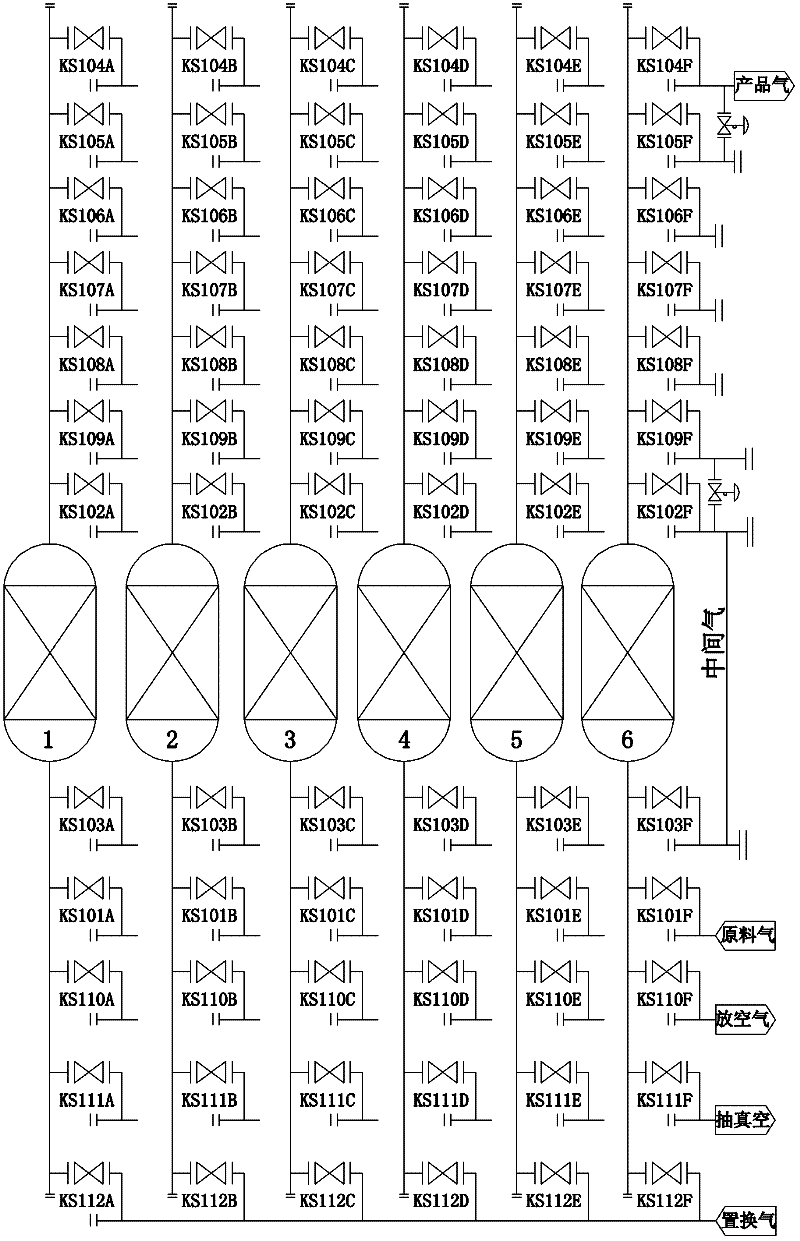

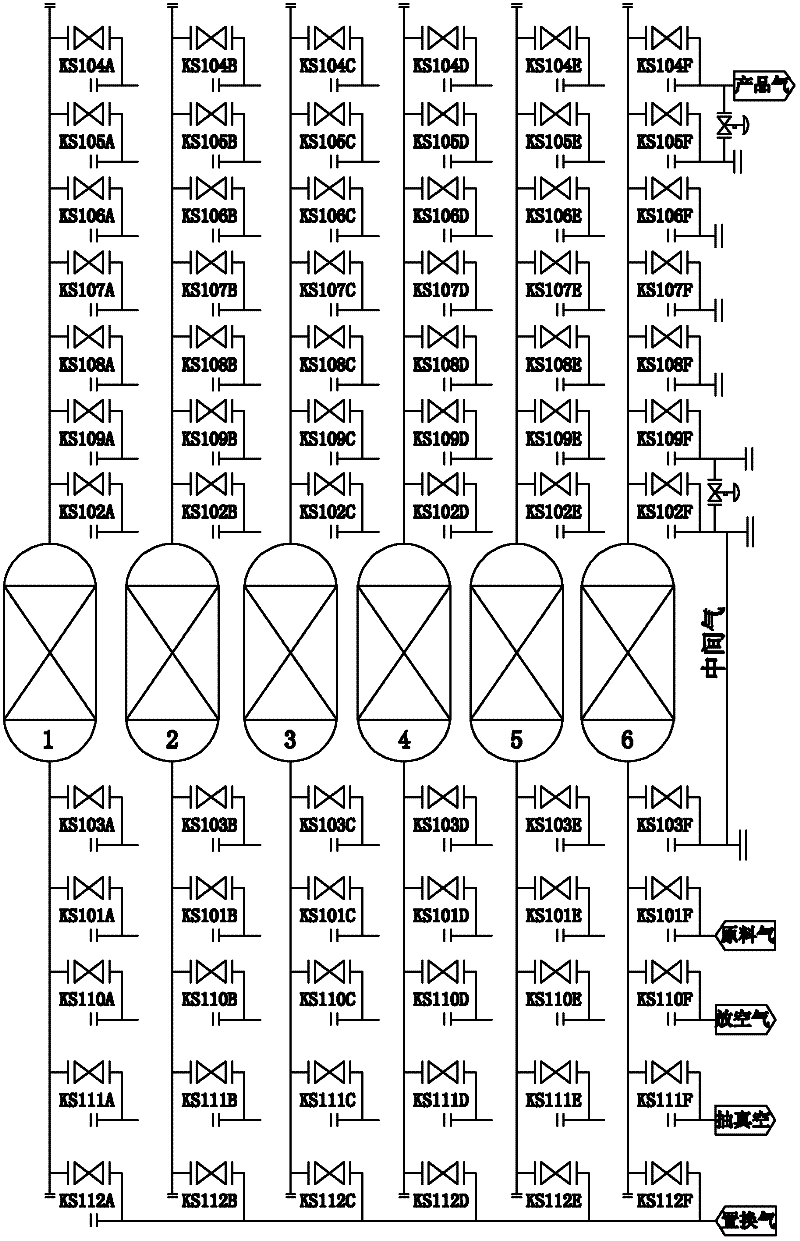

[0018] Embodiment: a kind of pressure swing adsorption gas separation process (see attached figure 1 ), there are six adsorption towers parallel to complete the gas separation and adsorption process, which are the first adsorption tower 1, the second adsorption tower 2, the third adsorption tower 3, the fourth adsorption tower 4, the fifth adsorption tower 5 and the sixth adsorption tower Tower 6, the process flow includes 7 processes, namely adsorption, depressurization, replacement, venting, vacuuming, boosting and charging. In the first gas separation process, the corresponding boosting process is filled with raw material gas to complete.

[0019] Taking the adsorption of the first adsorption tower as an example, the steps are as follows: (1) The adsorption process is series adsorption, which is completed by two adsorption towers, including the first adsorption tower and the second adsorption tower. The two adsorption towers are divided into one-stage adsorption tower and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com