Cut-off tool and method for machining end-face circular deep groove

A cut-off knife and arc-shaped technology, applied in the field of cut-off knives, can solve problems such as inability to process normally, insufficient overall rigidity of the tool, and low cutting efficiency, and achieve the effects of easy quality assurance, improved cutting conditions, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] based on the following Figure 5 ~ Figure 8 , specify the preferred embodiment of the present invention:

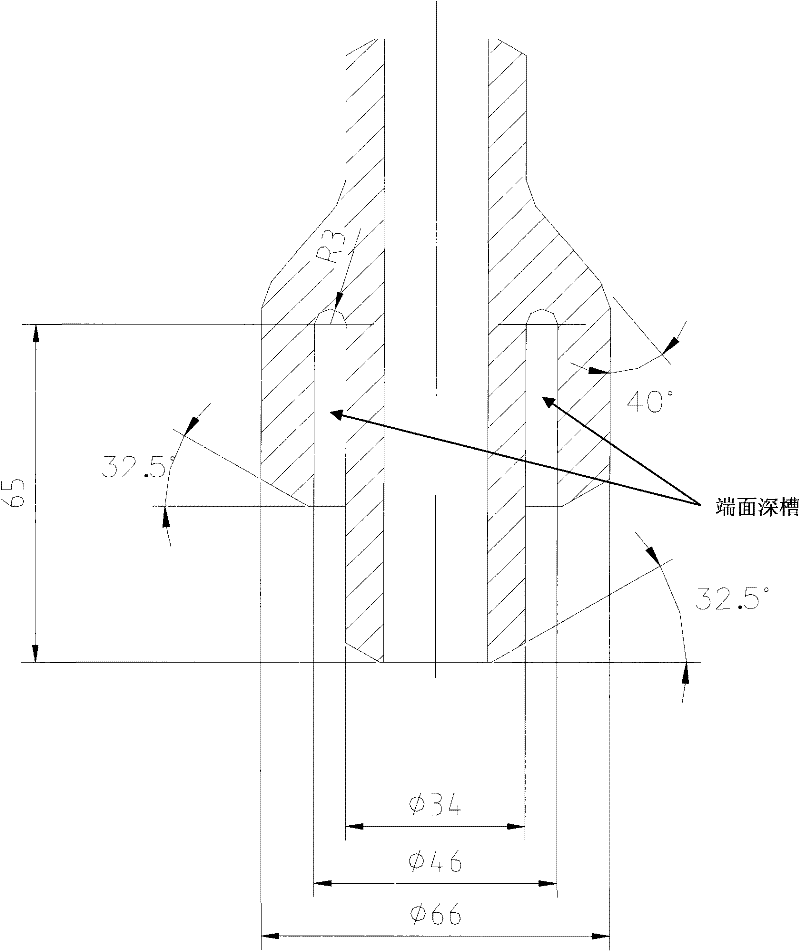

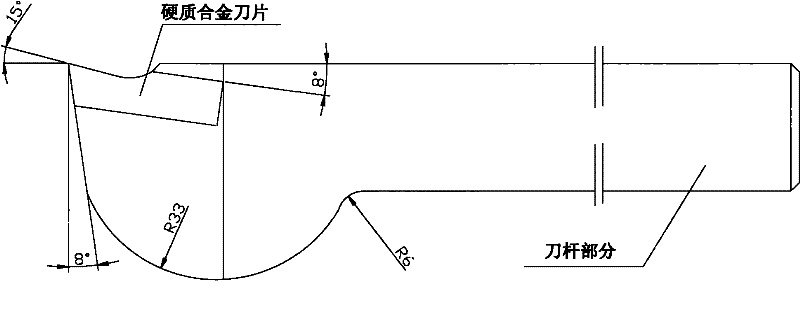

[0043] Such as Figure 5 ~ Figure 7 As shown, it shows a cut-off knife for processing a deep arc-shaped end face with a width of 6 mm and a depth of 65 mm. The cut-off knife includes a handle 1 and a blade 2. The blade 2 has a rake angle α, a relief angle β and The chip breaker 201, the rake angle α, the rear angle β and the geometric parameters of the chip breaker 201 are not significantly different from those of ordinary cutting tools. The rake angle α is 15°, the rear angle β is 5°, and the radius of the chip breaker 201 is 6mm ;

[0044] The two sides of the blade 2 of the cutting knife are arc-shaped, and the outer arc R out The radius is less than the outer diameter (23mm) of the arc-shaped deep groove on the end face, which is 21mm, and the inner arc R in The radius is greater than the inner diameter (17mm) of the arc-shaped deep groove on the end face, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com