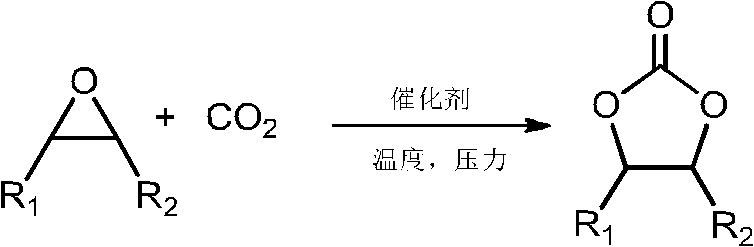

Method for preparing cyclic carbonate by catalyzing with ionic liquid

A technology of cyclic carbonate and ionic liquid, applied in the direction of organic chemistry, etc., can solve the problems of high catalyst cost, low catalytic activity, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

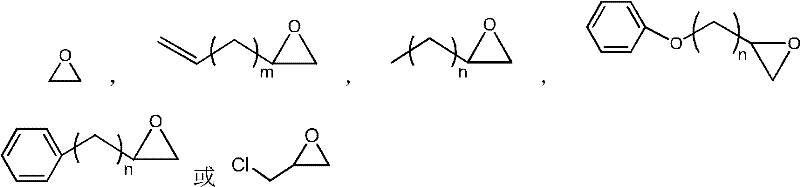

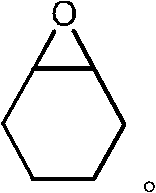

Method used

Image

Examples

Embodiment 1

[0020]

[0021] Implementation method: in a 100ml stainless steel autoclave, add 1-methyl-4-hydroxyethyl-1,2,4-triazole bromide (R=CH in the structural formula) successively 3 , R 1 =(CH 2 ) 2 OH, X=Br) 3.0mmol, 14ml propylene oxide (1a) (0.2mol), a closed reactor, filled with 1.0MPa of carbon dioxide, the temperature is controlled by a temperature controller to slowly rise to 110 ° C, and then the reaction pressure is controlled to 2.0 MPa, react for 1.0 hour. After the reaction, the reactor was cooled to 5° C., and excess carbon dioxide was slowly released. After the catalyst was separated by filtration, the product obtained was analyzed by gas chromatography, and the product (2a) was obtained with a selectivity of 99.5% and a yield of 99%.

Embodiment 2

[0023] With embodiment 1, catalyst used is 1-methyl-4-ethyl-1,2,4-triazole bromide (R=CH in the structural formula 3 , R 1 =CH 2 CH 3 , X=Br) 3.0mmol, other conditions remain unchanged, the selectivity of product (2a) is 99.8%, and the yield is 82%.

Embodiment 3

[0025] With embodiment 1, catalyst used is 1-methyl-4-hydroxyethyl-1,2,4-triazole chloride (R=CH in the structural formula 3 , R 1 =CH 2 CH 3 OH, X=Cl) 3.0 mmol, other conditions unchanged, the selectivity of (2a) was 99%, and the yield was 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com