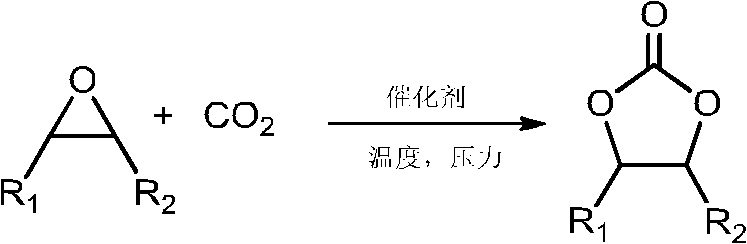

Method for catalyzing and preparing annular carbonic ester by supported ionic liquid

A technology of cyclic carbonate and ionic liquid, which is applied in organic chemistry and other fields, and can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]

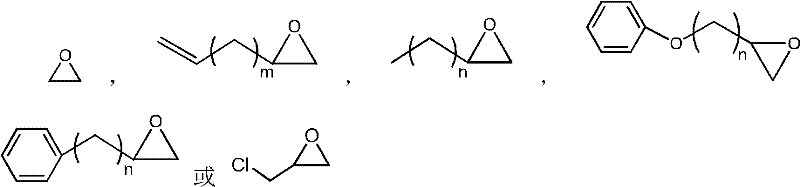

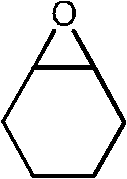

[0021] Implementation method: in a 100ml stainless steel autoclave, add the 4-hydroxyethyl-1,2,4-triazole bromide of SBA-15 load successively (n=2 in the structural formula, R 1 =OH, X=Br) 1.5g (1.7mmol, 1.2mol% based on the content of the ionic liquid, the same below), 10ml propylene oxide (1a) (0.143mol), a closed reactor, filled with 1.0Mpa pressure For carbon dioxide, the temperature was controlled by a temperature controller to slowly rise to 110° C., and then the reaction pressure was controlled to 2.0 MPa, and the reaction was carried out for 2.0 hours. After the reaction, the reactor was cooled to 5° C., and excess carbon dioxide was slowly released. After the catalyst was separated by filtration, the obtained product (2a) was analyzed by gas chromatography. The selectivity was 99.8%, and the yield was 99%.

Embodiment 2

[0023] Same as Example 1, the catalyst used is 4-ethyl-1,2,4-triazole bromide supported by SBA-15 (n=2 in the structural formula, R 1 =H, X=Br) 1.5g (about 2.2mmol), and other conditions remain unchanged, the selectivity of product (2a) is 99.0%, and the yield is 80%.

Embodiment 3

[0025] Same as Example 1, the catalyst used is 4-carboxypropyl-1,2,4-triazole bromide supported by SBA-15 (n=2 in the structural formula, R 1 =COOH, X=Br) 1.5g (about 1.2mmol), other conditions remain unchanged, the product (2a) was obtained with a selectivity of 99.0% and a yield of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com