Novel intelligent pneumatic automatic structure pattern machine

A pattern machine, a new type of technology, applied in floral stitch sewing machines, cloth press mechanisms, sewing machine components, etc., can solve problems such as the inability to freely adjust the pressure of the presser foot, transmission failures of mechanical parts, and inconvenient movement of equipment. To achieve the effect of diversified functions, smooth and smooth movement, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

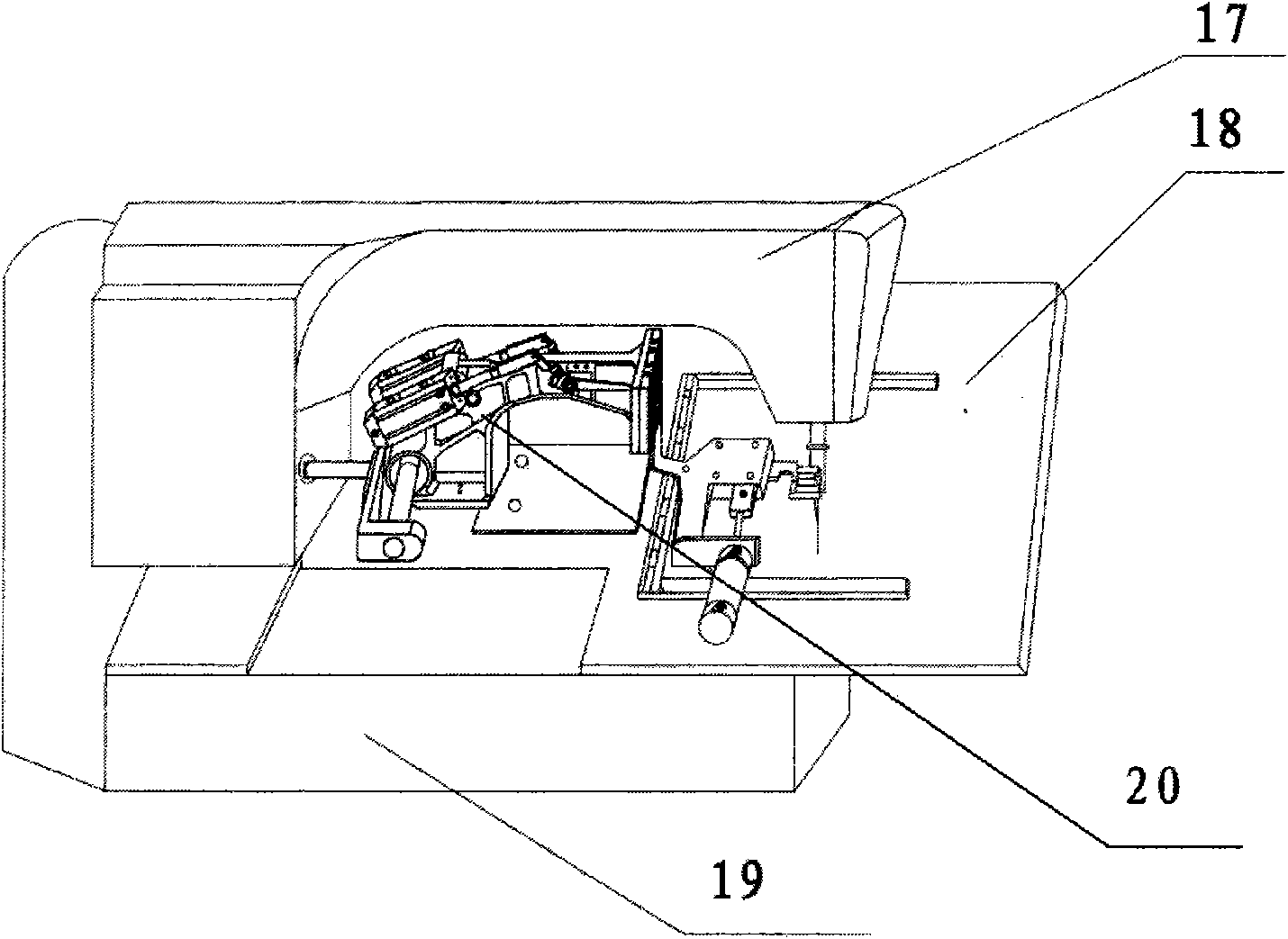

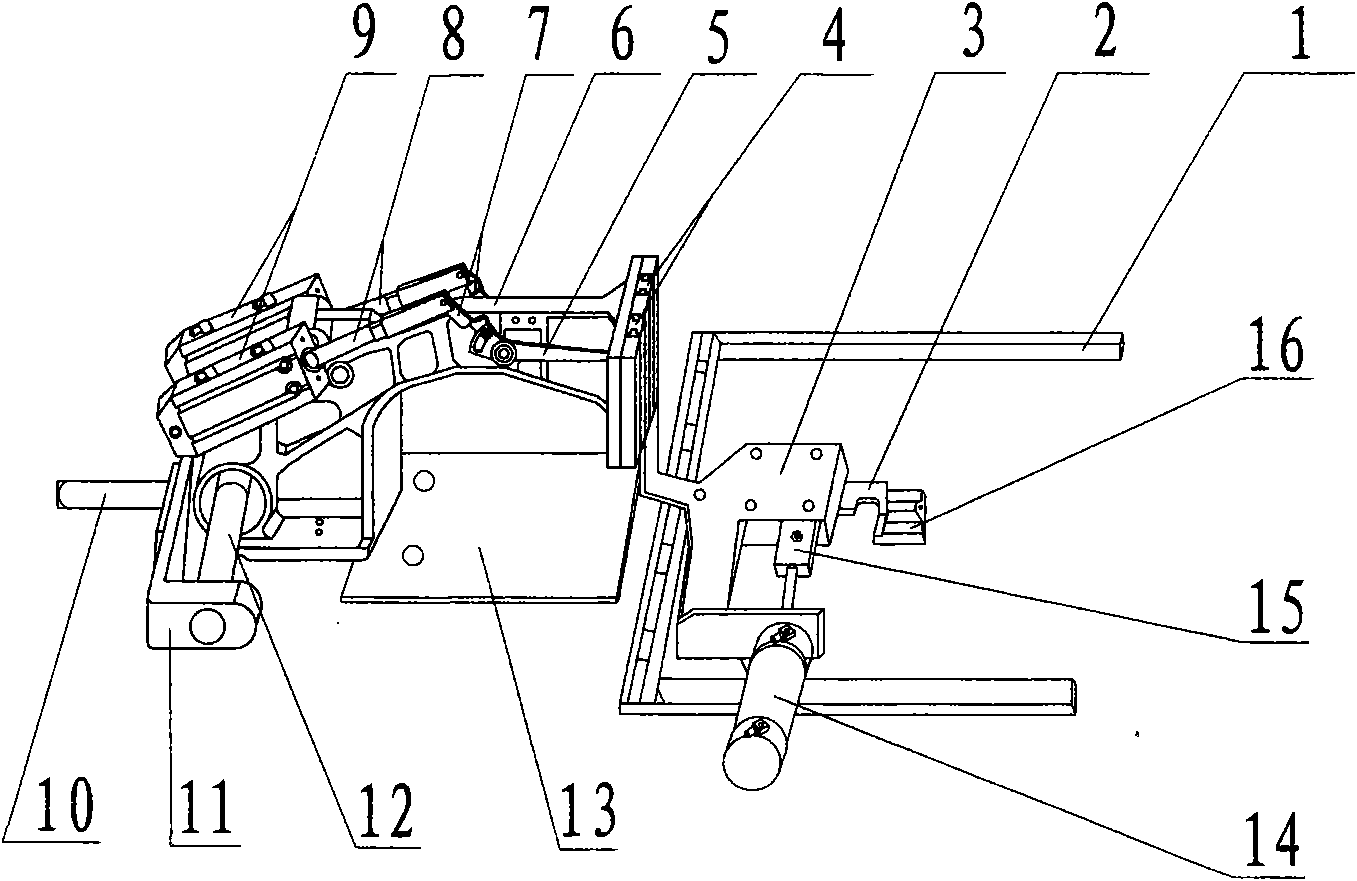

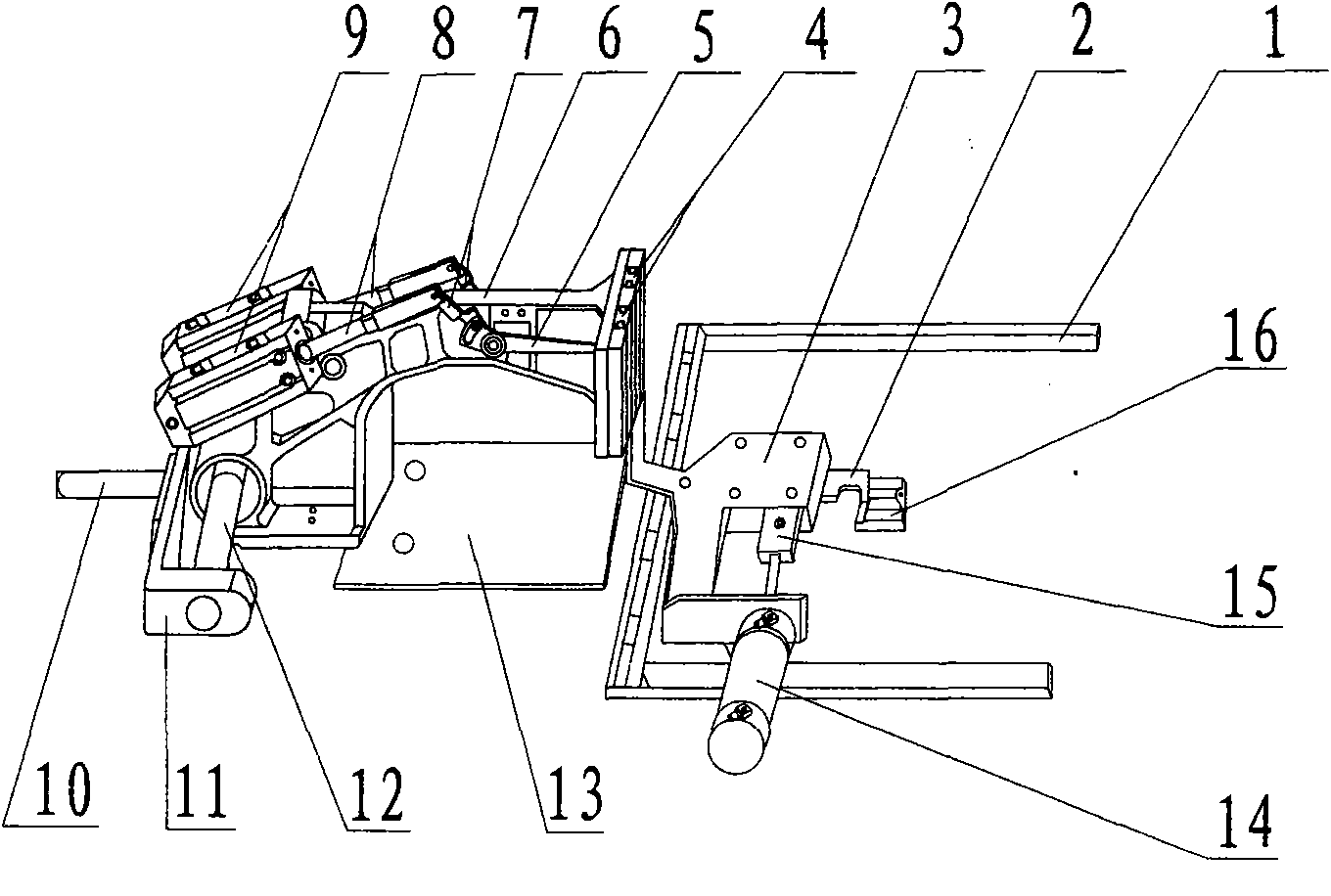

[0010] according to figure 1 , 2 As shown, after the machine is powered on, cloth is placed on the table 18 of the working surface, the computer control system drives the main shaft to move, and at the same time, the cylinder 9 works to push the Y drive shaft 10 to move back and forth. In the center, the cylinder drives the movement. The material is excellent, polished and lubricated. One end is installed on the cylinder drive shaft, and the other end is connected to the X-axis bracket. It is fixed with a mounting plate and bolted tightly. At the same time, it drives the X-direction travel axis 12 to move left and right. The X-axis support is rectangular as a whole. The thickness of the two ends and the Y transmission shaft is 15 mm. Also under the presser arm, the material is excellent, polished and lubricated, the presser arm is at the back, the edge is 12mm, and the bottom 10mm is a through hole, through which the X-direction travel axis passes. The presser arm moves alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com