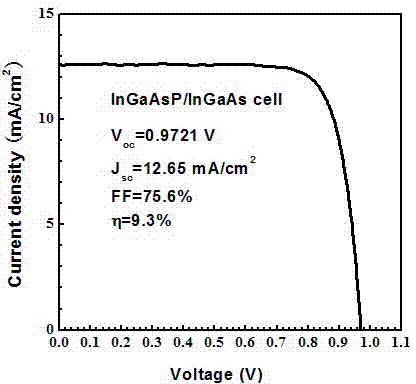

Double-junction serial InGaAs/InGaAsP (indium gallium arsenium/indium gallium arsenium phosphorus) double-end solar cell and manufacturing method thereof

A double-junction tandem, solar cell technology, applied in the field of solar photovoltaics, can solve difficult costs, increase system integration and other problems, achieve the effect of reducing high costs, solving electrode design and alignment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more obvious and easy to understand, the detailed description is as follows in conjunction with specific embodiments of the present invention.

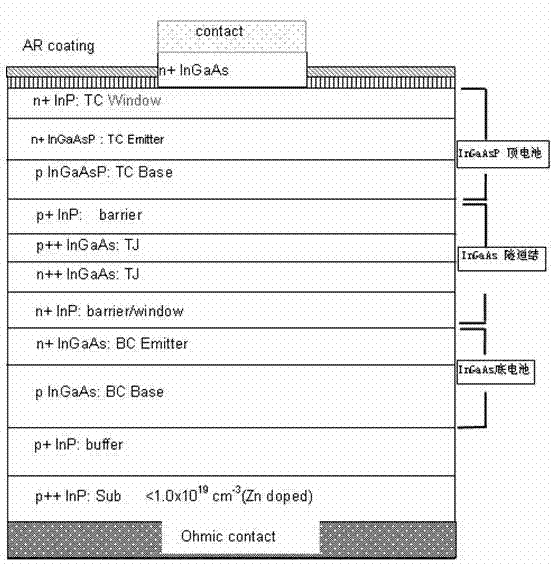

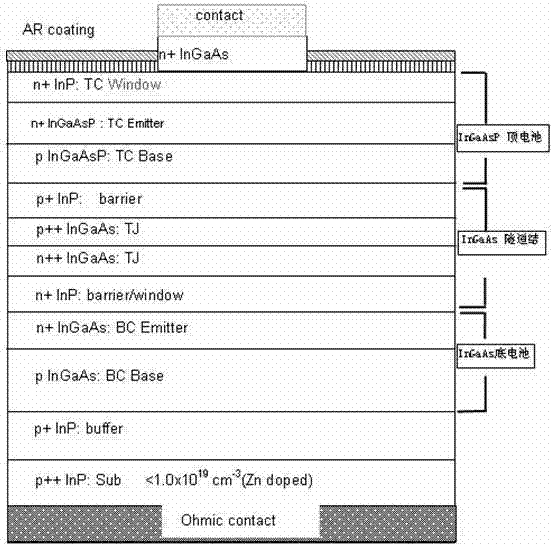

[0023] 1) Growth of epitaxial material on InP substrate

[0024] like figure 1 Shown is a schematic structural view of the two-junction tandem InGaAs / InGaAsP double-terminal solar cell of the present invention. Depend on figure 1 It can be clearly seen that the double-terminal solar cell is an InGaAs and InGaAsP double-terminal solar cell structure grown in series based on a single InP substrate and using p+InGaAs / n+InGaAs as a tunnel junction.

[0025] The upper layer of the InP substrate is an InGaAs bottom cell, including p InGaAs:BC Base and n+ InGaAs:BC Emitter double-layer structure; the upper layer of the InGaAs bottom cell is a tunnel junction, including the top and bottom buffer layers and the p++ between them InGaAs:TJ, n++ InGaAs:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com