Composite graphite particles and lithium secondary battery using the same

A technology of composite graphite and particles, which is applied in the field of negative electrodes, lithium secondary batteries, and negative electrode pastes. It can solve the problems of low charging characteristics and insufficient material cycle characteristics, and achieve the effect of excellent characteristics and high lithium ion acceptance capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

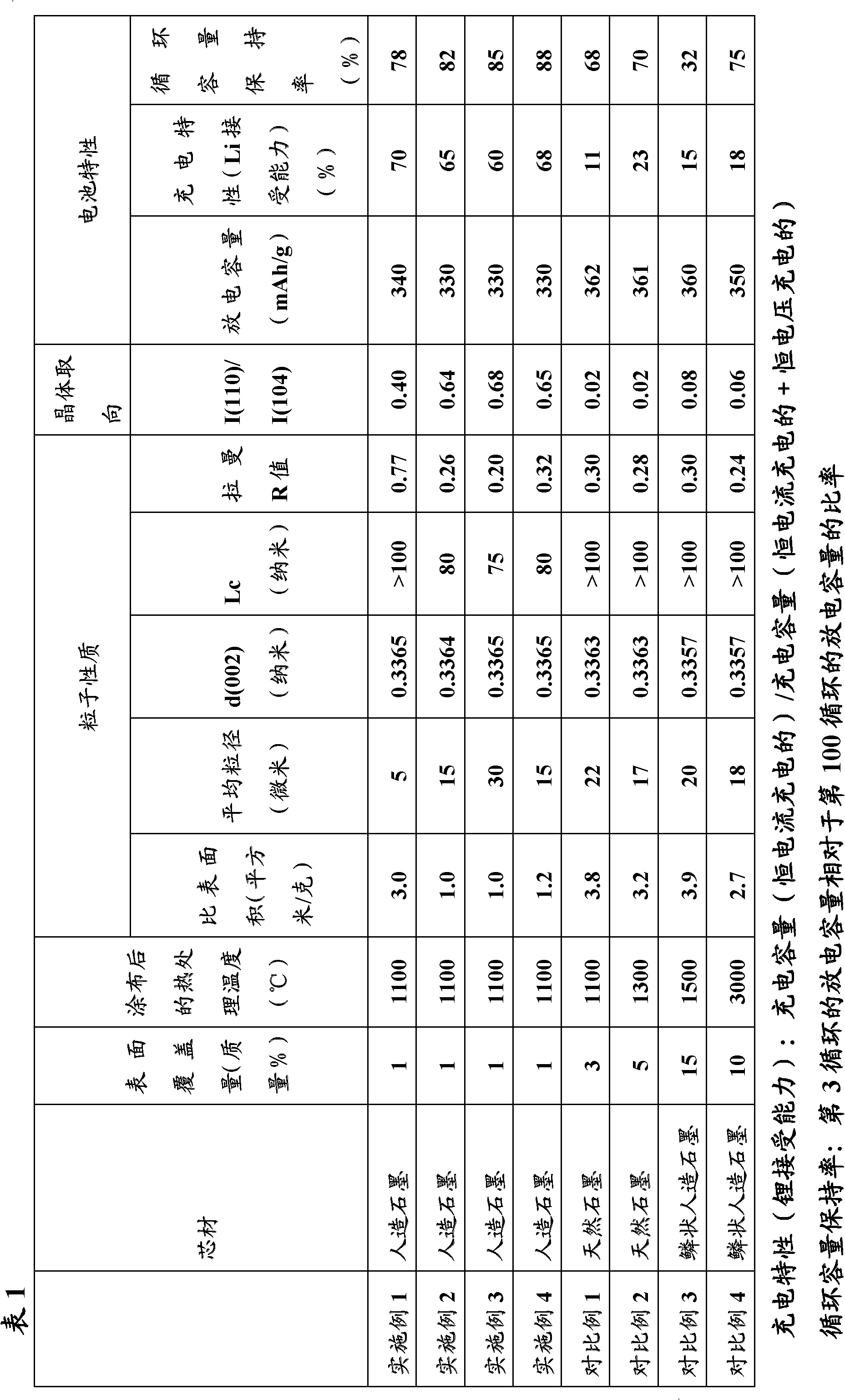

[0121] Petroleum coke is used as a material and pulverized into powder with an average particle size of 5 microns or less. The powder was heat-treated at 3000°C in an Acheson furnace to obtain a core material with a d value of 0.3359 nm. To this was added the isotropic pitch in powder form in an amount of 1% by mass of the core material. Then, heat treatment was performed at 3000° C. under an argon atmosphere, thereby obtaining the composite graphite of the present invention. The evaluation results for this graphite material are shown in Table 1.

Embodiment 2

[0123] Petroleum coke is used as a material and pulverized into a powder with an average particle size of 15 microns or less. The powder was heat-treated at 3000°C in an Acheson furnace to obtain a core material with a d value of 0.3359 nm. To this was added the isotropic pitch in powder form in an amount of 1% by mass of the core material. Then, heat treatment was performed at 1100° C. under an argon atmosphere, thereby obtaining the composite graphite of the present invention. The evaluation results of the obtained graphite materials are shown in Table 1.

Embodiment 3

[0125] Petroleum coke is used as a material and pulverized into powder with an average particle size of 30 microns or less. The powder was heat-treated at 3000°C in an Acheson furnace to obtain a core material with a d value of 0.3359 nm. To this was added the isotropic pitch in powder form in an amount of 1% by mass of the core material. Then, heat treatment was performed at 1100° C. under an argon atmosphere, thereby obtaining the composite graphite of the present invention. The evaluation results of the obtained graphite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com