Black water and grey water treatment apparatus through modular film method

A treatment device, a technology for black and gray water, which is applied in the fields of water/sewage multi-stage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc. Achieve the effect of reducing production and use costs, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

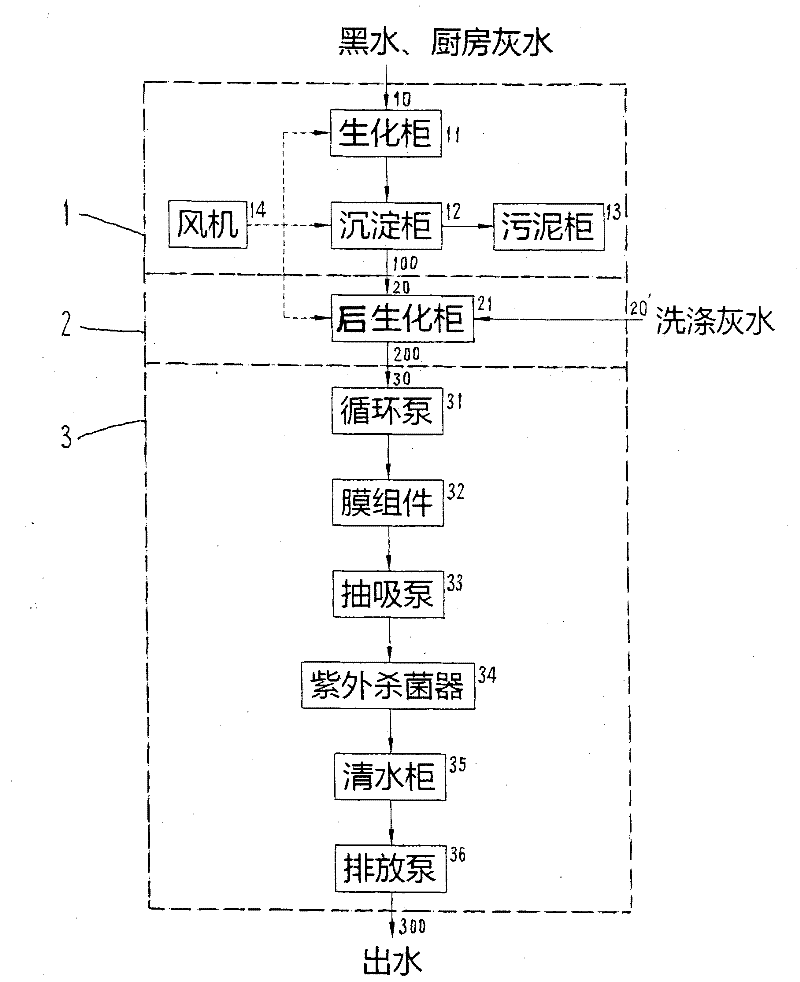

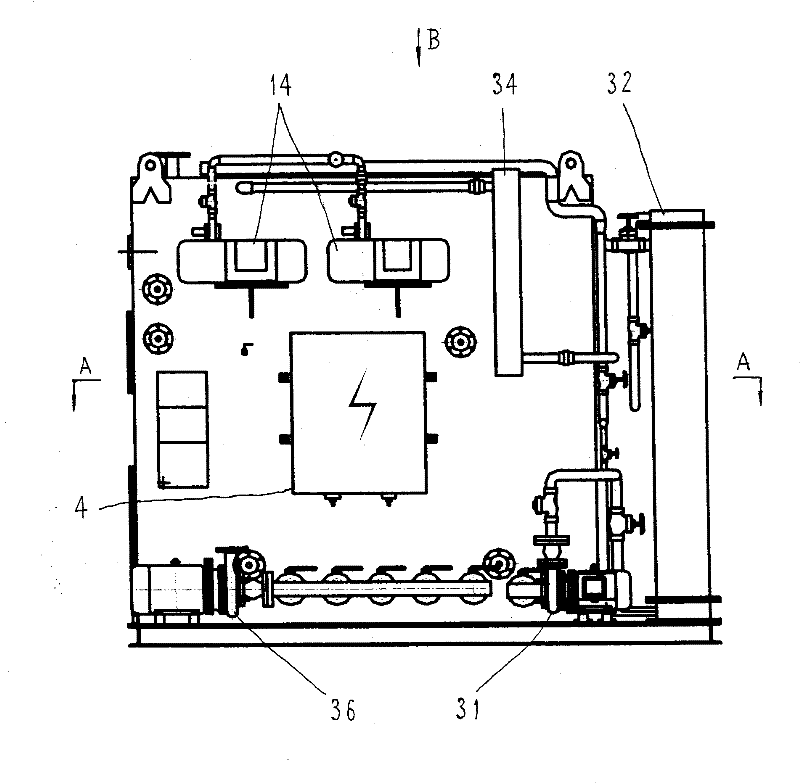

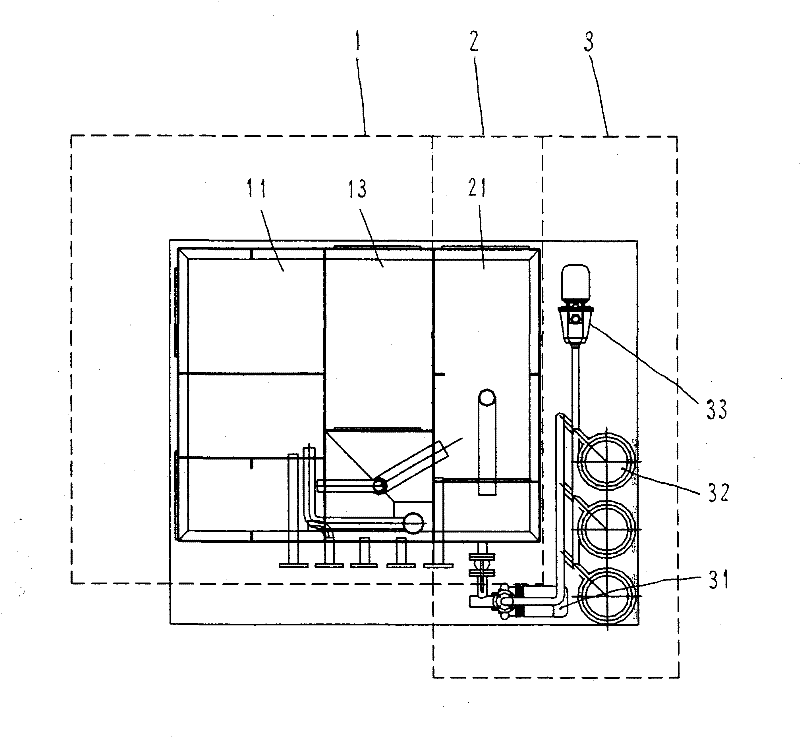

[0010] refer to figure 1 , 2 , the modular membrane method black and ash water treatment device includes the first module 1, the second module 2, the third module 3 and the control box 4, and the combination of the modules adopts the existing sequencing batch biochemical method and membrane separation method combined control The automatic control technology of box 4, its processing flow is as follows figure 1 shown.

[0011] The first module is a biochemical high sludge load sewage treatment module, including a first water inlet 10, a biochemical tank 11, a sedimentation tank 12, a sludge tank 13, a fan 14 and a first water outlet 100, and its function is biochemical degradation and sludge storage, the effluent water quality of this module is stable in a small range, which is an essential requirement for the realization of modularization in the present invention, and it provides a relatively standard boundary condition for subsequent modules; wherein:

[0012] The first wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com