Preparation method and application of MNO2 catalyst for deep mineralization of phenol wastewater at room temperature

A kind of catalyst, deep technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as high equipment requirements and complex processes, and achieve application prospects Extensive, easy-to-use, easy-to-repeat effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The MnO used in the deep mineralization of phenol wastewater at normal temperature proposed by the present invention 2 The preparation method of catalyst comprises the following steps:

[0032] (1) Potassium permanganate and reduction auxiliary agent are mixed, the mass ratio of mixing is: potassium permanganate: reduction auxiliary agent=1: (0.1-0.6), add deionized water 70mL-100mL in the mixture, make the mixture The mass volume concentration is 5.0-10.769g / L, obtains a suspension, and the described reduction auxiliary agent is manganese sulfate monohydrate or ammonium oxalate monohydrate;

[0033] (2) Place the suspension in the above step (1) in a hydrothermal reaction vessel or a water bath reaction vessel, react for 12 hours at 80-200 degrees Celsius, and after the solution is cooled to room temperature, carry out centrifugation, and use deionized water washing the solid obtained by centrifugation;

[0034] (3) Heating the solid in the above step (3) to 90-120 d...

Embodiment 1

[0042] (1) 1.0g potassium permanganate is mixed with 0.15g manganese sulfate monohydrate, and 70mL deionized water is added thereto to obtain a suspension;

[0043] (2) Place the suspension in the above step (1) in a hydrothermal reaction vessel or a water bath reaction vessel, react at 200 degrees Celsius for 12 hours, cool the solution to room temperature, then centrifuge, wash and centrifuge with deionized water isolated solid;

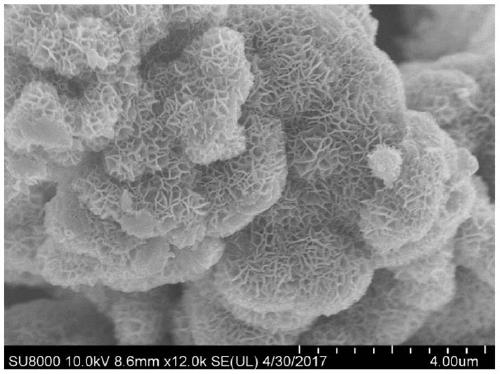

[0044] (3) Heat the solid in the above step (2) to 105 degrees Celsius, keep it warm for 24 hours, and obtain 001 crystal face MnO with the ability to mineralize phenol wastewater at atmospheric pressure after natural cooling 2 catalyst.

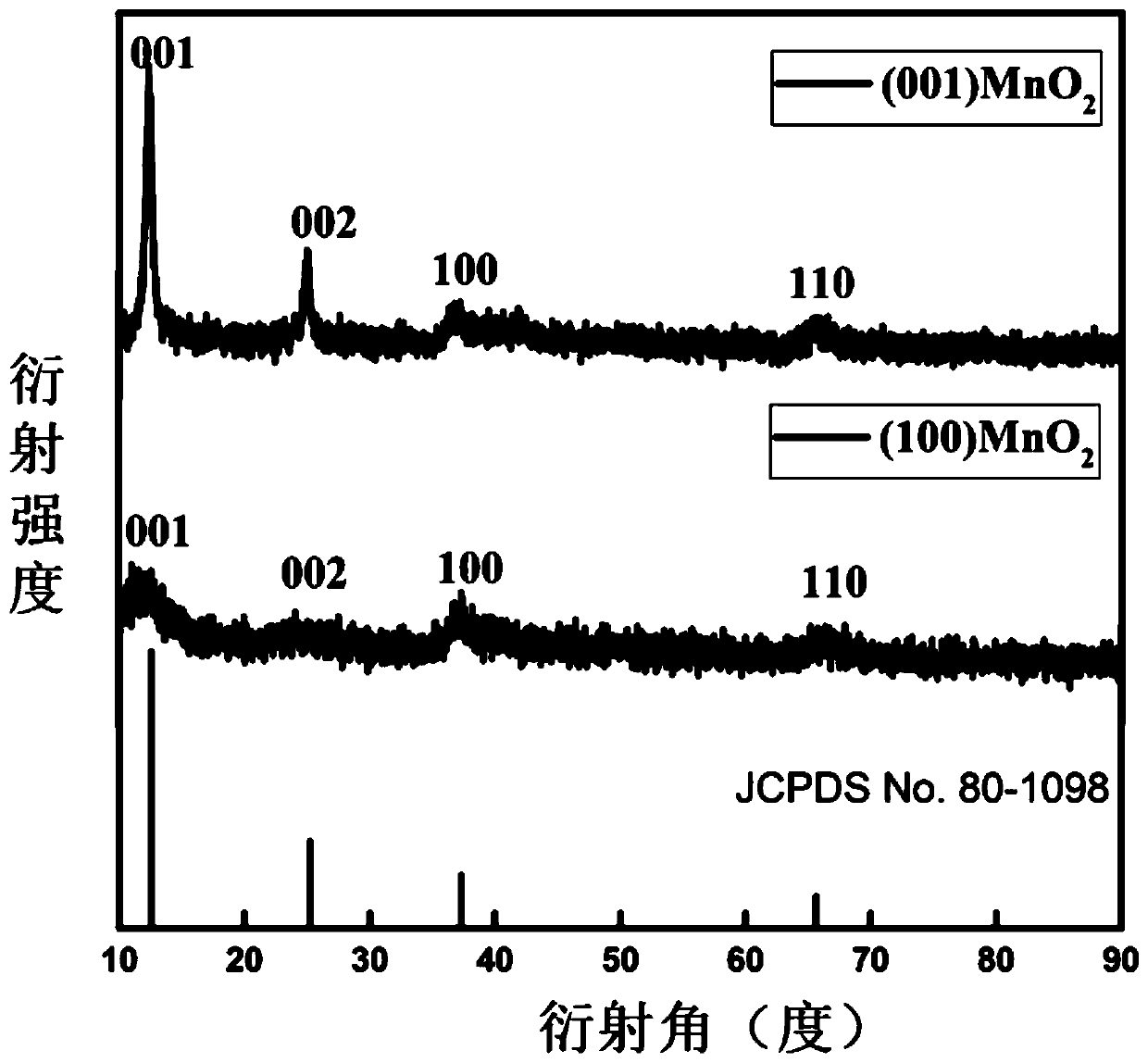

[0045] Adopt U.S. Rigaku D / max-2400 type X-ray diffractometer to test the MnO prepared by Example 1 2 The crystal structure of the catalyst is as figure 1 The XRD pattern shown. It can be seen from the spectra that MnO 2 The crystallinity is not very good, the peaks at 12.3°, 24.6°, 36.5° and 65.5° are simil...

Embodiment 2

[0047] (1) 1.0g potassium permanganate and 0.3g manganese sulfate monohydrate are mixed, and 100mL deionized water is added thereto to obtain a suspension;

[0048] (2) Place the suspension in the above step (1) in a hydrothermal reaction vessel or a water bath reaction vessel, react at 200 degrees Celsius for 15 hours, cool the solution to room temperature, then centrifuge, wash and centrifuge with deionized water isolated solid;

[0049] (3) Heat the solid in the above step (2) to 100 degrees Celsius, keep it warm for 30 hours, and naturally cool to obtain 001 crystal face MnO with the ability to mineralize phenol wastewater at atmospheric pressure. 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com