Method for preparing substitute natural gas by coal-based syngas

A technology for coal-based synthesis gas and natural gas substitutes, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of small production capacity, unsuitable for large-scale supply of natural gas, narrow application range, etc., and achieve the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

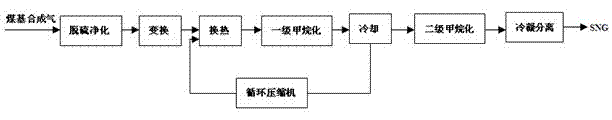

[0019] In this example, the method for producing substitute natural gas by using coal-based synthesis gas is as follows, and the flow chart is shown in figure 1 :

[0020] After desulfurization and transformation of coal-based syngas, the composition (vol%) of the obtained mixed gas is: H 2 68, CH 4 9, CO 19, CO 2 3. The total sulfur content is less than 0.1ppm. Under the action of the nickel catalyst system supported by alumina, the first-stage methanation reaction is carried out to obtain a mixed gas with a methane content of about 45%. The pressure of the first-stage methanation reactor is about is 2.0MPa, the reactor inlet temperature is about 230°C; part of the mixed gas is returned to the raw material gas before the reactor to dilute CO and CO 2 concentration, the circulation ratio is about 1.2:1, and the raw material gas composition (vol%) after dilution is: H 2 41.5, CH 4 45, CO 8.5, CO 2 4.

[0021] The mixed gas composition (vol%) at the outlet of the fi...

Embodiment 2

[0024] In this example, the method for producing substitute natural gas by using coal-based synthesis gas is as follows, and the flow chart is shown in figure 1 :

[0025] After desulfurization and transformation of coal-based syngas, the composition (vol%) of the obtained mixed gas is: H 2 68, CH 4 9, CO 19, CO 2 3. The total sulfur content is less than 0.1ppm. Under the action of the nickel catalyst system with pseudo-boehmite as the carrier, the first-stage methanation reaction is carried out to obtain a mixed gas with a methane content of about 50%. The first-stage methanation reactor The pressure is about 5.0MPa, and the reactor inlet temperature is about 260°C; part of the mixed gas is returned to the raw material gas before the reactor to dilute the CO and CO 2 concentration, the circulation ratio is about 1:1, and the raw material gas composition (vol%) after dilution is: H 2 40,CH 4 47, CO 8, CO 2 4.

[0026] The mixed gas composition (vol%) at the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com