Weldable fine grain structural steel S355NL/S355NLZ35 steel plate and its production method

A production method and technology of structural steel, applied in the direction of manufacturing converters, workpiece surface treatment equipment, metal rolling, etc., can solve problems such as increased production costs, unfavorable enterprise development and competition, increased production energy consumption, etc., to reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]Through KR molten iron pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, stack cooling, and normalizing processes, a weldable fine-grain structural steel S355NL / S355NLZ35 steel plate is obtained , it contains the following chemical composition in mass percent (unit, wt%): C: 0.16, Si: 0.35, Mn: 1.40, P: 0.015, S: 0.003, Als: 0.025, V: 0.025, Ti: 0.020, others are Fe and residual elements.

Embodiment 2

[0025] Through KR molten iron pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, stack cooling, and normalizing processes, a weldable fine-grain structural steel S355NL / S355NLZ35 steel plate is obtained , it contains the following chemical composition in mass percent (unit, wt%): C: 0.12, Si: 0.43, Mn: 1.20, P: 0.017, S: 0.001, Als: 0.040, V: 0.015, Ti: 0.025, others are Fe and residual elements.

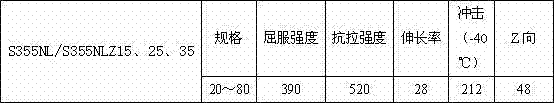

[0026] Analysis of mechanical properties

[0027] The composition and mechanical properties shall be implemented according to EN10025-1, and the specific mechanical properties are shown in Table 1 below

[0028] Table 1 Mechanical properties of weldable fine grain structural steel S355NL / S355NLZ35 steel plate

[0029]

[0030] A total of 120 batches of weldable fine-grained structural steel S355NL / S355NLZ35 steel plates with a thickness of 20-80 mm were trial-produced, amon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com