Polyphenylene sulfide synthetic hair filaments and processes for preparing the same

A technology of polyphenylene sulfide and fiber, which is applied in the field of polyphenylene sulfide synthetic hair fiber and its preparation, and can solve the problem that the working condition of PPS resin depends on the melt index, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

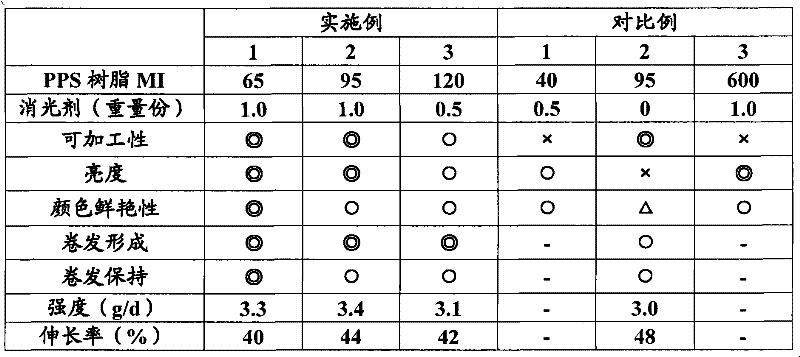

Embodiment 1-3

[0066] 100 parts by weight of the PPS resin shown in the following Table 1 of MI was spun, and the amount of the silica matting agent was 0.5-1.0 parts by weight. The barrel temperature of the spinning machine was 290° C., the head temperature was set at 313° C., a 160-hole nozzle was used to prepare undrawn fibers, and the fibers were drawn 3.8 times using a roll drawing machine. The stretched fibers were heated using a roller heat treatment device at 240° C., and heated under tension. Immediately thereafter, 50 dtex synthetic hair fibers were prepared by relaxation and slight wave formation in a heating cabinet at 150° C. in the stress-free state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com