Thermal insulating device for pavement asphalt mixture stirring cylinder

A technology of asphalt mixture and heat preservation device, which is applied in the field of road construction machinery, can solve the problems of time spent on heating up and affecting the quality of the mixture, and achieve the effects of reducing the cooling range, low cost and high heat preservation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

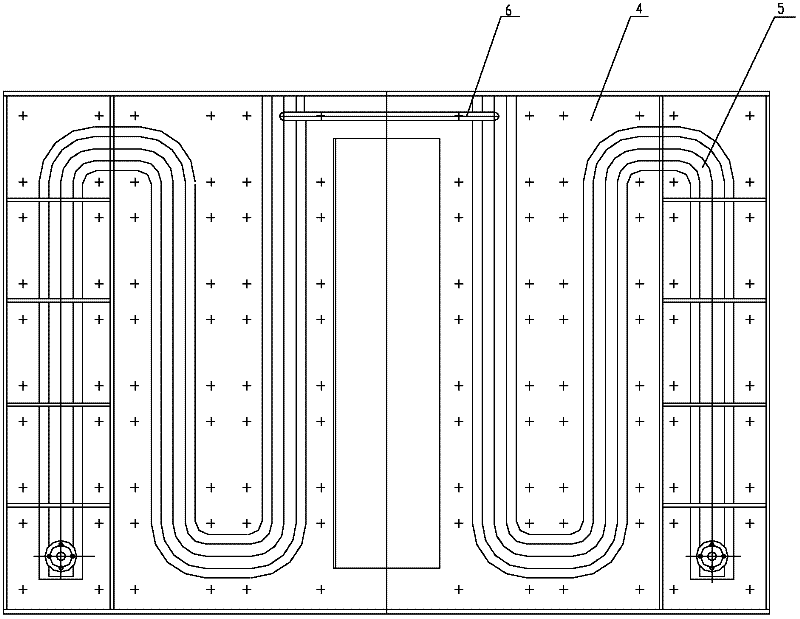

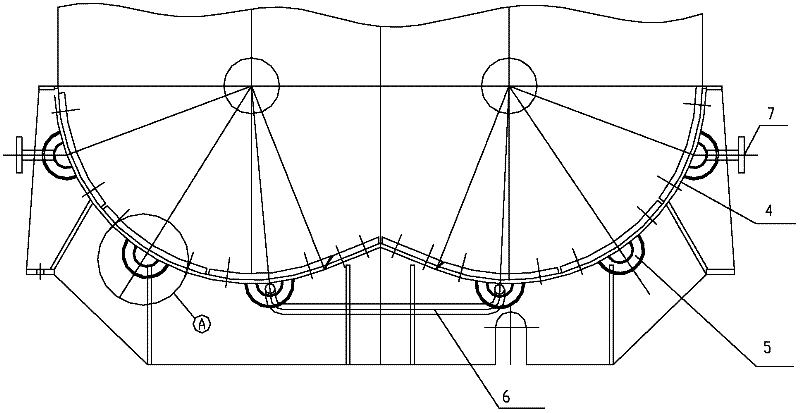

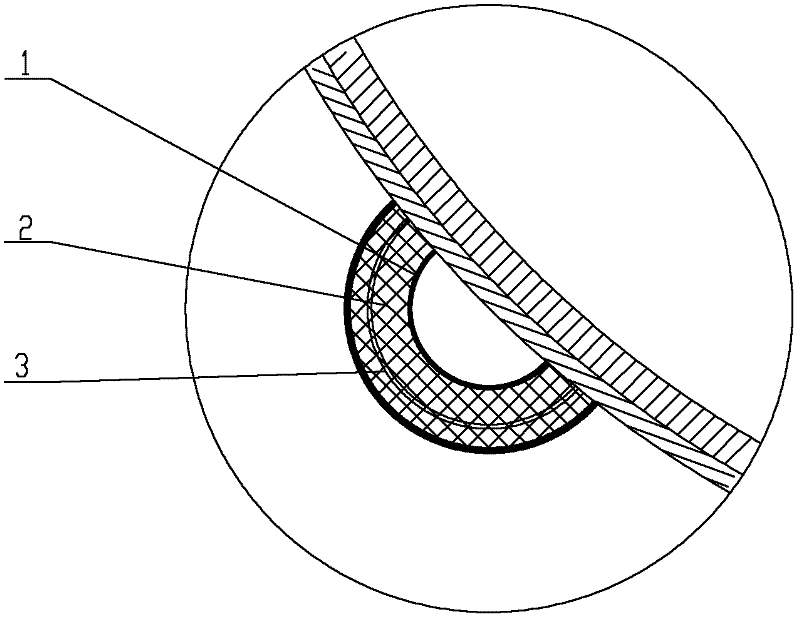

[0022] A semicircular thermal oil pipe layer 1 is welded on the outer wall 4 of the mixing tank, the pipe specification is φ32×3, a semicircular rock wool layer 2 is placed on the outer surface of the semicircular thermal oil pipe layer, and the material specification is φ89, and a semicircular sheath layer 3 is placed on the outer insulation layer. The specification is φ89δ2, the foreskin is spot-welded with the outer wall of the mixing tank, the inlet and outlet of the thermal oil pipe are welded at the inlet and outlet of the thermal oil pipe, and the insulating pipe connection flange 7 of the thermal insulation pipe 5 connected with the heat transfer oil pipe system is welded, and the heat transfer oil is kept warm from one side through the connecting pipe 6 Pipe 5 flows to the insulation pipe 5 on the other side.

Embodiment 2

[0024] The radius of the semicircular skin layer is 35mm, the radius of the semicircular thermal oil pipe layer is 15mm, the thickness of the semicircular rock wool layer is 20mm, and the rest of the structure is the same as that of Example 1.

Embodiment 3

[0026] The radius of the semicircular skin layer is 60mm, the radius of the semicircular thermal oil pipe layer is 25mm, the thickness of the semicircular rock wool layer is 35mm, and the rest of the structure is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com