[0002] In terms of vehicle drive types, there are mainly some wheel drive models and

all wheel drive models. From the perspective of safety, all wheel drive models have higher safety; taking our common four-wheel vehicles as an example, they can be divided into two types:

Wheel drive vehicles, referred to as two-wheel drive vehicles, all-wheel drive vehicles, referred to as all-wheel drive vehicles, when the conditions are the same, such as: vehicle weight, road conditions, and tire type, driving status, etc. The average value of the friction force must be twice the average value of the friction force required by a single driving wheel of a four-wheel drive vehicle to drive the vehicle, and the maximum friction force between the wheel and the ground is equal. When the friction force reaches the maximum friction force and dangerous situations such as

tail flick, sideslip, understeer, and oversteer occur, the all-wheel drive vehicle can still drive normally; but the vehicle will face another problem when driving, when the driving wheels slip, such as: ice and

snow roads When the driving wheel is suspended in the air, sandy ground, etc., the vehicle will not be able to transmit the driving force to the driving wheel with adhesion, causing the vehicle to be unable to drive. This often happens in poor road conditions or in the wild. At this time, Any one of the four driving wheels of the all-wheel drive slips, and the vehicle cannot run normally, and when any of the two drive wheels of the two-wheel drive slips, the vehicle cannot run normally, but the two random The slipping of the driving wheels does not affect the normal driving of the vehicle. From this point of view, the probability of vehicle slipping in an all-wheel drive vehicle is twice that of a two-wheel drive vehicle. Therefore, it is considered to equip the vehicle with a differential lock to lock the slipping driving wheels to prevent them from idling. The power is transmitted to the driving wheels with adhesion, so that the vehicle can get out of trouble. Therefore, when the all-wheel drive is equipped with a differential lock, it will have the greatest safety and passability compared with the two-wheel drive.

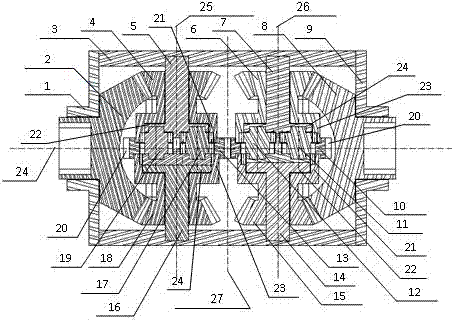

The current differential lock is mainly divided into a mechanical differential lock with a purely mechanical structure and an

electronic differential lock that uses

electronic equipment to monitor the wheel speed difference and locks the slipping

drive wheel with a mechanical structure. Compared with a mechanical differential lock with a purely mechanical structure Representative ones are Tosen differential lock and viscous

coupling differential. Tosen differential lock has the characteristics of linear locking and sensitive response, but the production cost is high and the

power transmission efficiency is low. It is mainly used in high-end vehicles, and generally not in the bridge Differential lock use; viscous

coupling differential lock, which has the characteristics of low production cost and high fuel economy, but

slow responseThe

electronic differential lock locks the slipping wheels through the friction plate, which has the advantages of low production cost and linear locking, but the fuel economy is poor; and the electronic

clutch differential locks that are widely used now have poor fuel economy and relatively

slow response time. Long, hidden dangers of

electronic equipment and other issues, not suitable for front and rear axle differential locks, generally used with the

brake system[0003] For a rear-wheel drive car, the rotational speed of the left and right axle shafts of the differential is consistent with the rotational speed of the differential housing when driving straight on normal roads, but when the car is turning, driving on uneven roads or roads with low adhesion When driving, the drive wheels have insufficient adhesion, and the wheels on both sides move at different distances at the same time, resulting in unilateral slippage, which makes it difficult to drive and turn the car, increases

power consumption, and increases the wear of some parts and wheels in the

transmission system.

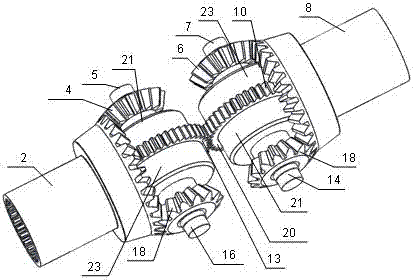

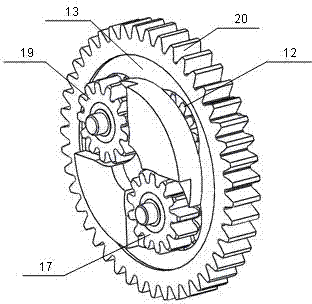

This problem is now solved by driving the two semi-shafts and wheels of the car separately at a differential speed. There are many types of differentials, such as traditional planetary bevel gears and spur gears. The torque-sensing differential responds quickly and can Realize real full-time four-wheel drive, but high cost and high

power consumptionThe viscous

coupling differential is low in cost and small in size, but the time-sharing four-wheel drive is usually the same as the two-wheel drive. According to the mode of the front drive plus the viscous coupling differential lock to drive the rear wheels, when the front wheels slip, the maximum can only send 50% of the power to the rear axle

Electronic

clutch differential lock, the price is higher

Login to View More

Login to View More  Login to View More

Login to View More