Condensate water recovery device

A technology for recycling device and condensate water, which is applied in the directions of supplementary water supply, preheating, steam generation, etc., can solve the problems of large temperature drop of condensate water, affecting energy saving effect, unfavorable energy saving and environmental protection, etc., achieving less temperature loss, reducing pipeline corrosion, high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

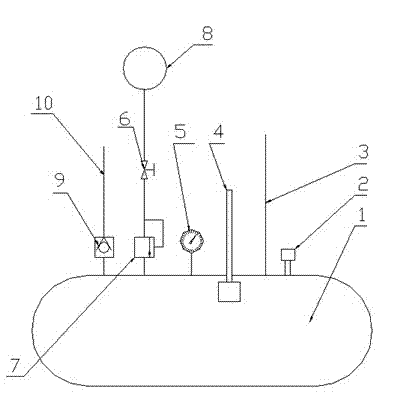

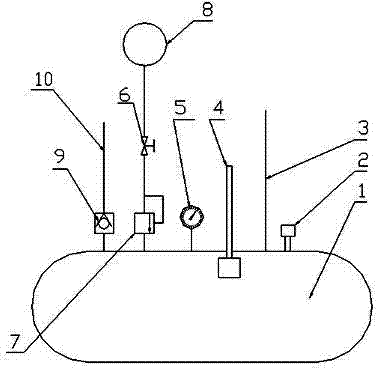

[0009] In the figure, the condensed water recovery device includes a water storage tank 1, a safety valve 2, an outlet pipe 3, a water level sensor 4, a pressure gauge 5, a stop valve 6, a pressure reducing valve 7, an air compressor 8, a one-way valve 9, The water inlet pipe 10, the water storage tank 1 of the present invention is an airtight container, and is also a place for temporary storage and transfer of condensed water. A safety valve 2, an outlet pipe 3, a water level sensor 4, and a pressure gauge are fixedly installed on the water storage tank 1 5. The outlet pipe 3 is connected to the water inlet of the boiler, the air compressor 8 is connected to the inside of the water storage tank 1 through the stop valve 6 and the pressure reducing valve 7, and the water inlet pipe 10 is connected to the inside of the gas storage tank 1 through the one-way valve 9 , The water inlet pipe 1 is connected to the condensed water outlet end of the condenser. When the water lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com