High-power electronic gun

An electron gun and high-power technology, which is applied in the field of electron guns, can solve problems such as discharge, unclean gun chamber, and large diameter of the electron gun base, and achieve the effects of reducing high-voltage discharge, balanced and effective overall structure, and small and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

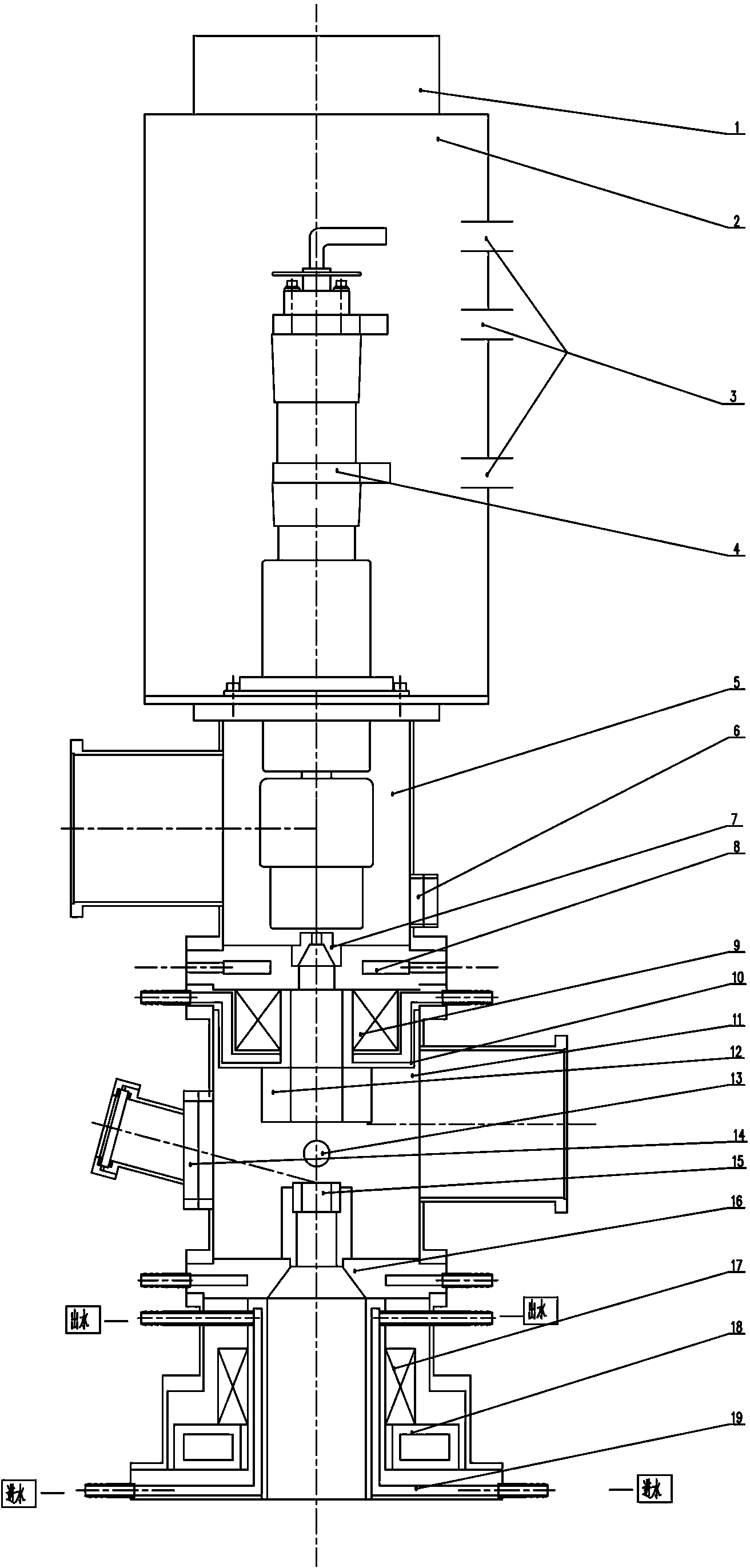

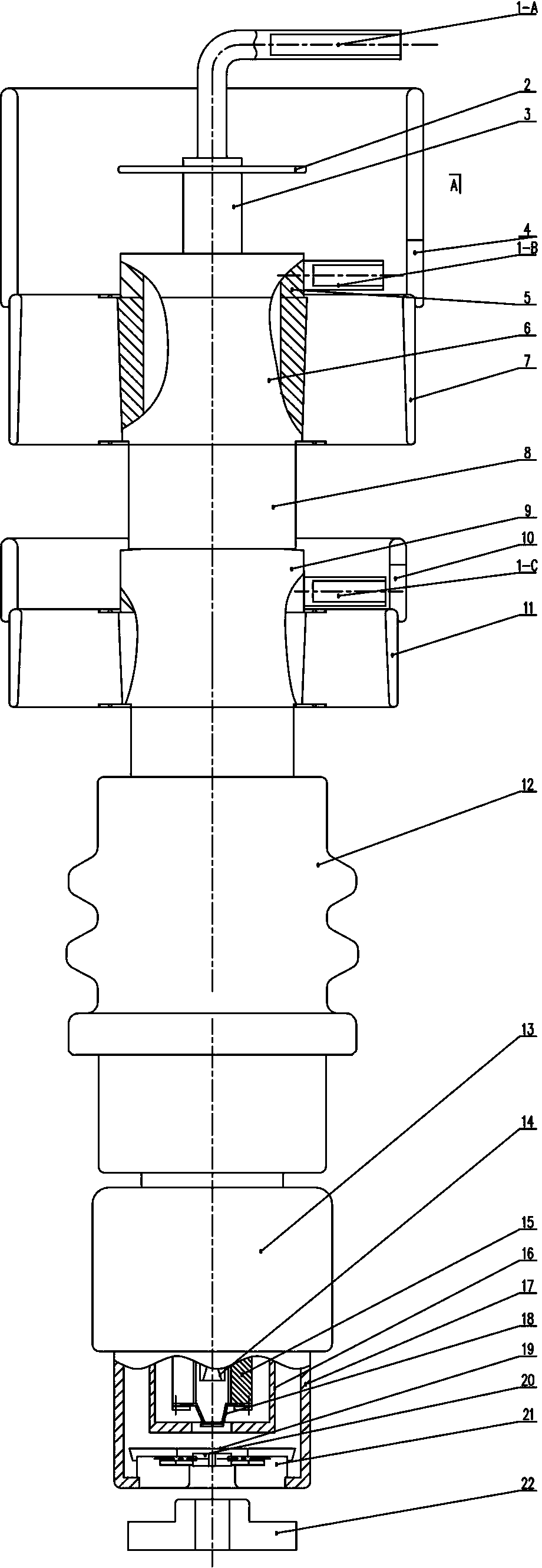

[0037] like figure 1 As shown, according to the path process of the electron beam, the high-power electron gun with the maximum stable working power of the present invention is 800kw, and its main components include the electron gun core 4, the anode 7, the first magnetic lens 9, the gate valve 12, and the argon gas delivery system 13. Block hole 15, second magnetic lens 17 and deflection scanning lens 18, which are respectively installed on gun chamber upper cylinder 5, anode seat 8, first magnetic lens cover 10, block hole seat 16, and gun body base 19.

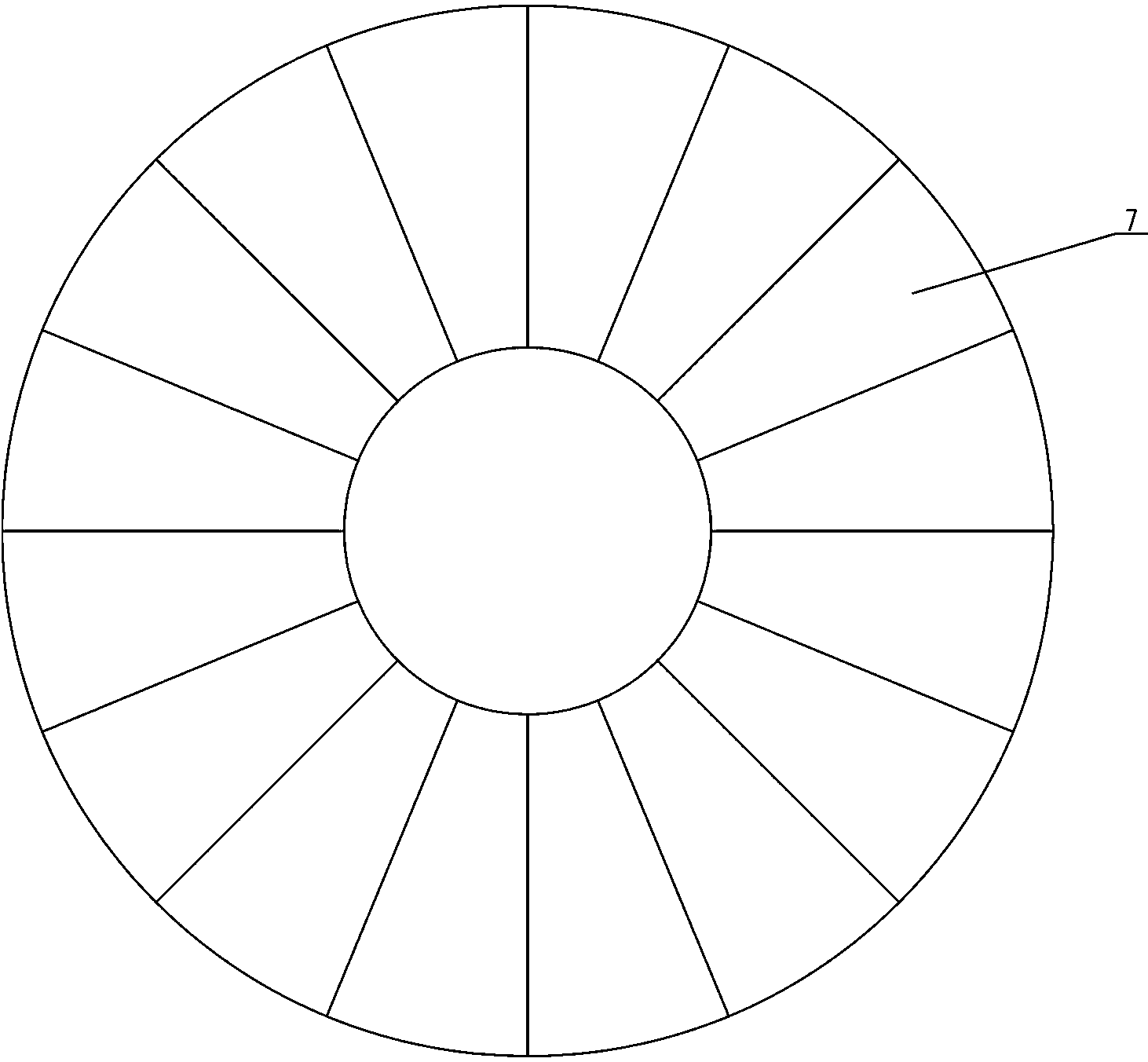

[0038] The gun core 4 described above is equipped with a cathode block and a beam focusing pole that match the high power of 800kw; an anode 7 that matches the high power gun core of 800kw is installed on the anode seat 8; in order to meet the requirements of the vacuum pressure difference of the high-power electron gun , two magnetic lenses 9 and 15 and blocking holes 13 matching the high power of 800kw are configured in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com