Over-frequency vibrating separator and separating system

A separation device, central transmission technology, applied in semi-permeable membrane separation, osmotic/dialysis water/sewage treatment, chemical instruments and methods, etc. Sewage treatment capacity, increase the effective filtration area, and the effect of high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

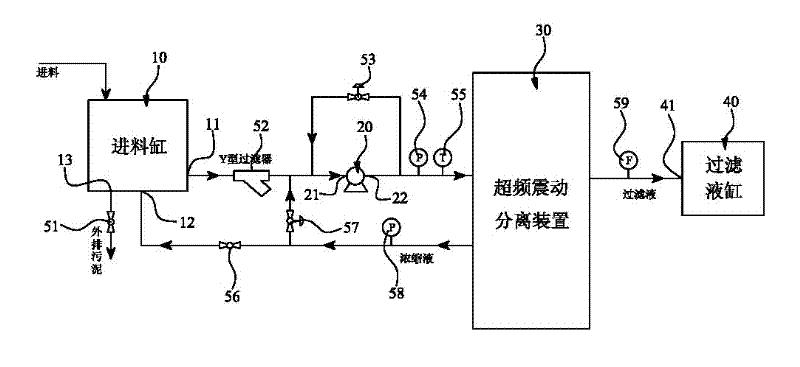

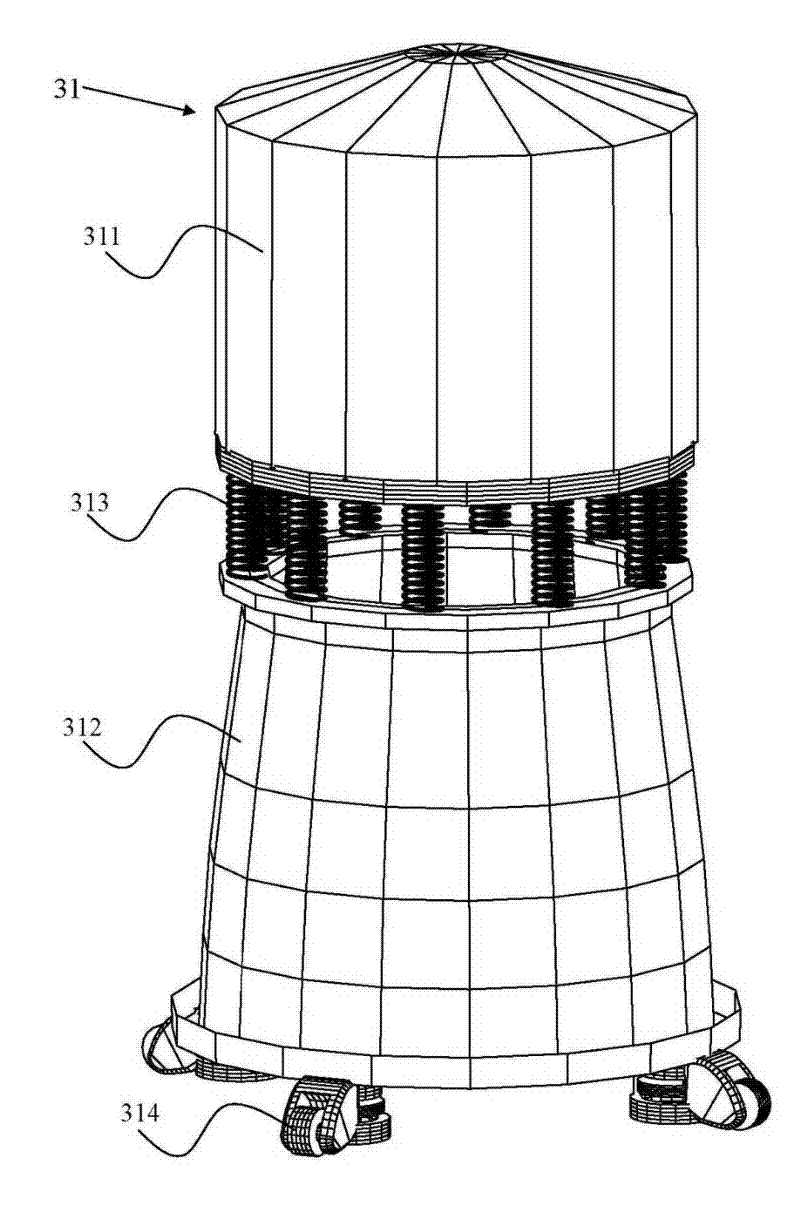

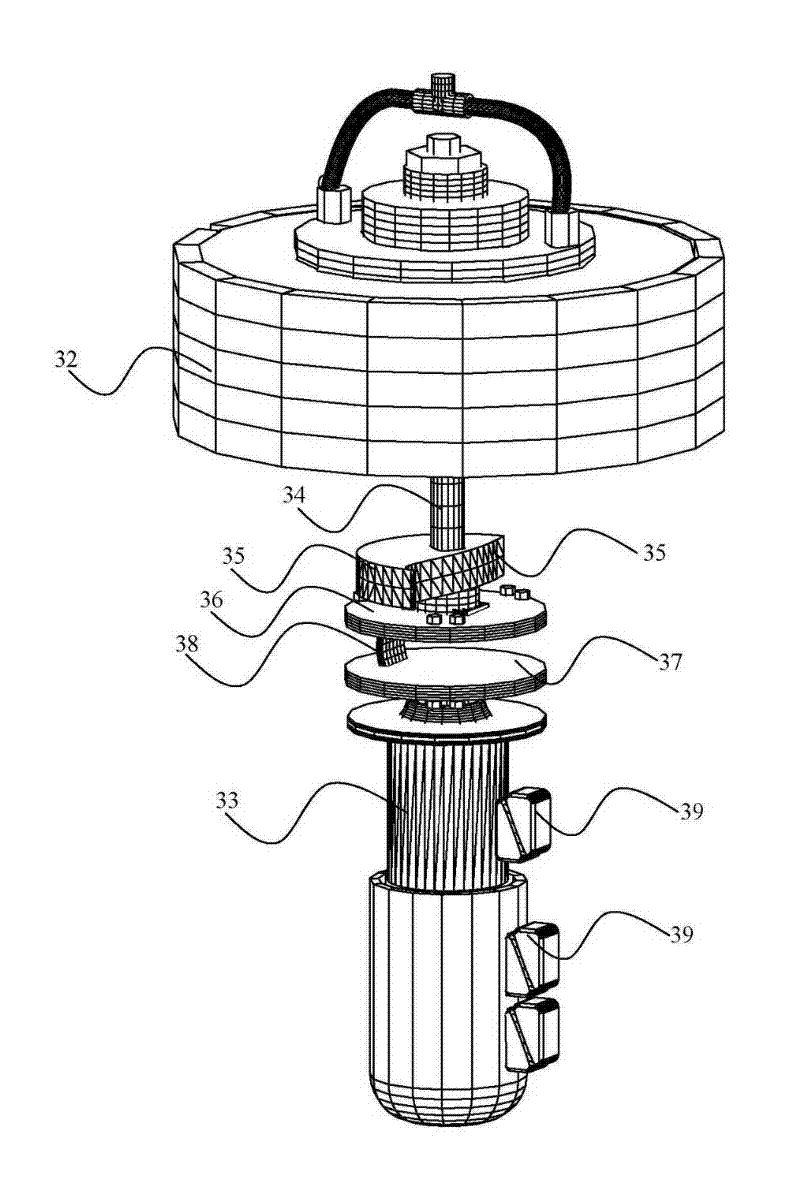

[0072] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a feed cylinder 10 , a feed pump 20 , an ultra-frequency vibration separation device 30 and a filtrate cylinder 40 .

[0073] Among them, such as figure 1 As shown, the feed tank 10 is used to load the sewage to be treated. The separation system in this embodiment is used to concentrate and separate the heavy metal sewage, but it is not limited to the concentration and separation of the heavy metal sewage, and can also be used for other various A kind of sewage is processed, and this feeding tank 10 has raw water output port 11, concentrated solution input port 12 and sludge output port 13, and this raw water output port 11 is arranged on the side of feeding tank 10, and this concentrated solution input port 12 and The sludge output port 13 is all arranged on the bottom of the feed tank 10, and the sludge output port 13 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com