Preparation method of Ag-AgCl-TiO2/rectorite composite photochemical catalyst

A rectorite and catalyst technology, applied in the field of preparation of Ag-AgCl-TiO2/rectorite composite photocatalyst, achieves high photocatalytic degradation activity, low reaction temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

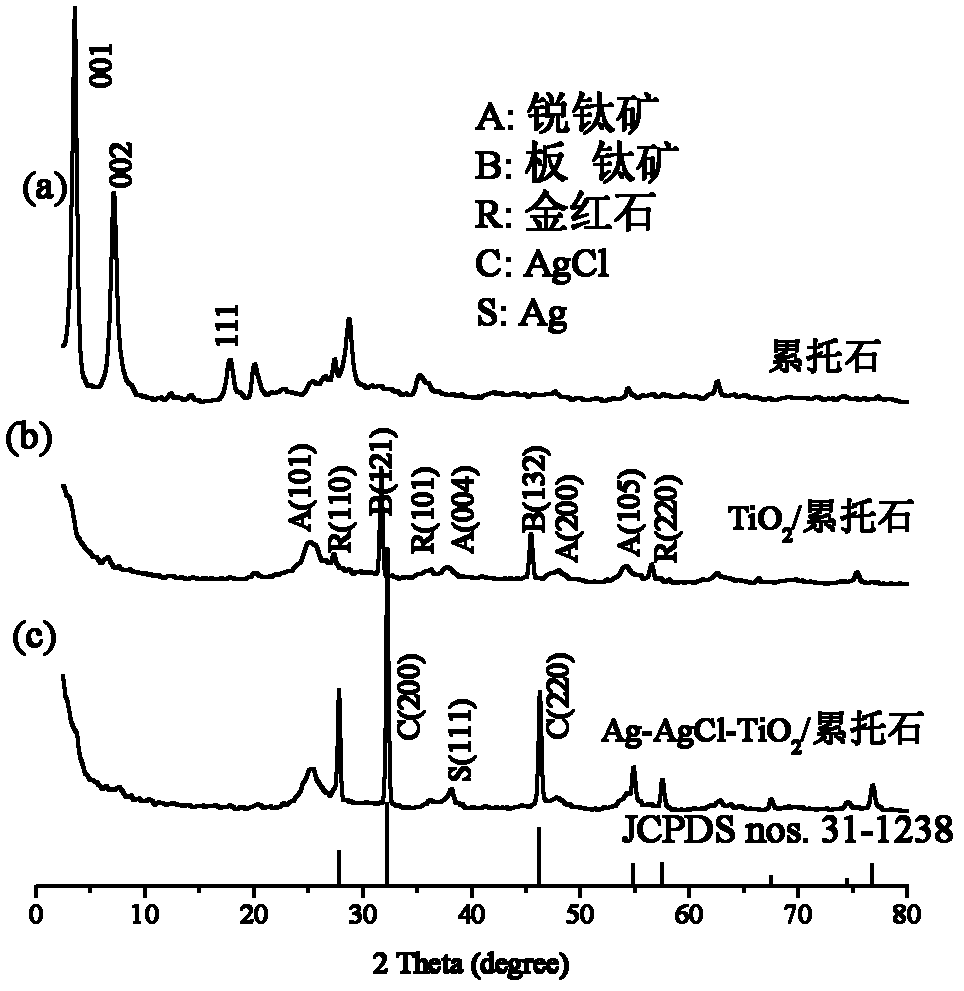

Image

Examples

Embodiment 1

[0024] Ag-AgCl-TiO 2 The preparation method of / rectorite composite photocatalyst, it comprises the following steps:

[0025] 1) Add 35mL of tetraisopropyl titanate solution dropwise into 18wt%-19wt% HCl solution under constant stirring at 25°C to obtain a molar ratio of [Ti] ions / [H] ions of 1:3.8 The solution was stirred for 3h to obtain light yellow transparent TiO 2 Pillar solution (or TiO 2 Sol).

[0026] 2) Weigh 2.5 g of rectorite into 250 mL of distilled water, and stir at room temperature for 5 h to obtain a 1 wt.% rectorite suspension.

[0027]By TiO 2 The ratio of the pillar solution and the rectorite suspension with a concentration of 1wt.% is 65mL: 250mL, and the TiO 2 Pillar solution (TiO 2 Sol) was dripped into the suspension solution of rectorite at a rate of 3 drops / 1 minute with a peristaltic pump, stirred at a constant temperature of 70°C for 3h, then aged at 25°C for 15h, and adjusted the pH value between 2.5-3.0 with 5M NaOH solution , centrifuged, r...

Embodiment 2

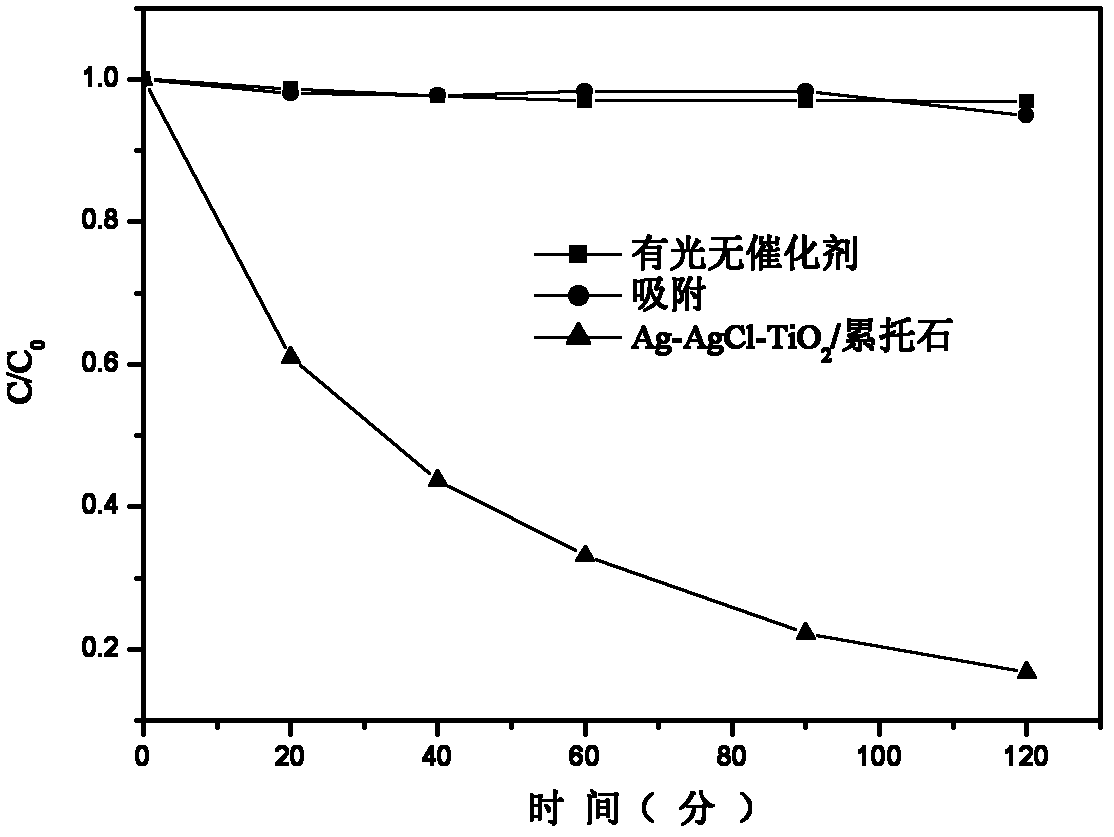

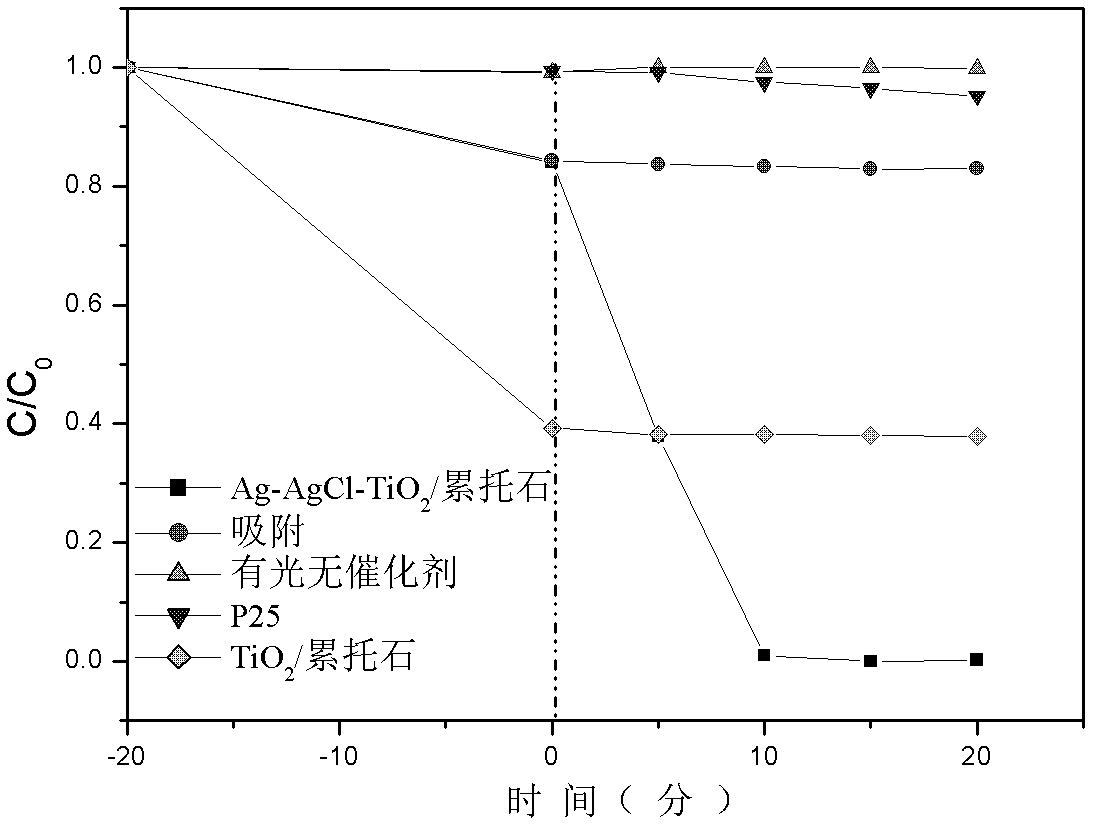

[0036] In order to test the effect of different titanium sources on Ag-AgCl-TiO 2 Influence of the photocatalytic performance of / rectorite composite photocatalyst, using organic titanium source tetraisopropyl titanate and inorganic titanium source titanium tetrachloride as raw materials respectively, other reaction conditions such as silver nitrate concentration (0.05mol / L), TiO 2 / Rectorite final pH value (2.5-3.0) and photoreduction time (3h) etc. are all identical with embodiment 1. The experimental results show that when titanium tetrachloride is used as the titanium source, the prepared Ag-AgCl-TiO 2 The degradation rate of acid red G / rectorite composite photocatalyst was 67.6%, and the adsorption performance of the catalytic material to organic dyes also decreased. It also shows that the Ag-AgCl-TiO prepared by this method 2 / rectorite composite photocatalyst has good photocatalytic performance under visible light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com