HP-RTM technology based method for molding automobile surface external decorative parts

An HP-RTM, automotive surface technology, which is applied in the field of automotive surface exterior trim parts formed by HP-RTM process, can solve the problems of high porosity, low production efficiency, and reduce production costs, so as to reduce porosity, improve accuracy, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

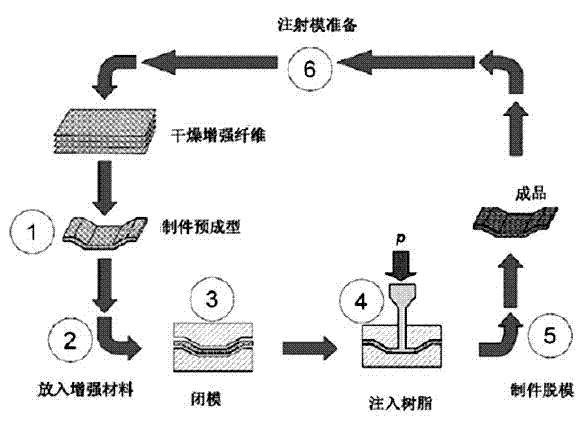

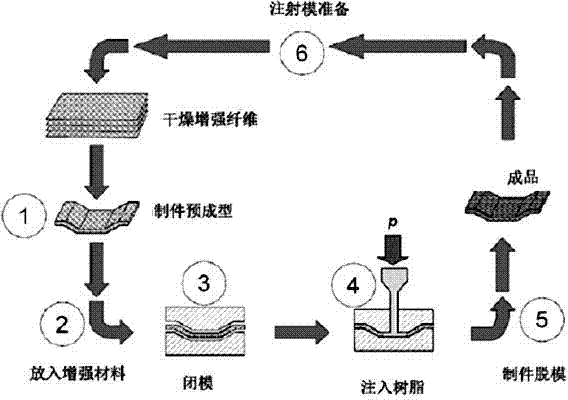

[0017] A kind of method of HP-RTM process molding automobile surface exterior trim, see figure 1 , the method uses vinyl resin as a matrix, carbon fiber as a reinforcement, adding a flame retardant and an antistatic agent, and adopts a high-pressure resin transfer molding process to form an automotive surface exterior trim. The specific steps are as follows:

[0018] Prepare a certain amount of vinyl resin (purchased from DSM Co., Ltd.), use 7% aluminum hydroxide as a flame retardant according to the mass of the matrix resin, and use 7% of the mass of the matrix resin as octadecyl dimethyl hydroxyethyl quaternary Ammonium nitrate is used as an antistatic agent, and the matrix, flame retardant, and antistatic agent are uniformly mixed to obtain the first resin system. In addition, methyl ethyl ketone peroxide (purchased from Baling Petrochemical Company Reagent Factory) and FR-32 polymerization inhibitor (purchased from Shanghai Unite Co., Ltd.) were prepared. The mass ratio...

Embodiment 2

[0020] Another HP-RTM method for forming automotive surface exterior parts. The method uses epoxy resin as a matrix, carbon fiber as a reinforcement, adding flame retardants and antistatic agents, and adopts a high-pressure resin transfer molding process to form automotive surfaces. Exterior parts, the specific steps are as follows:

[0021] Prepare a certain amount of epoxy resin, use 5% aluminum hydroxide as a flame retardant according to the mass of the matrix resin, and use 5% octadecyldimethylhydroxyethyl quaternary ammonium nitrate as an antistatic agent according to the mass of the matrix resin , uniformly mixing the matrix, the flame retardant, and the antistatic agent to obtain the first resin system. In addition, methyl ethyl ketone peroxide (purchased from Baling Petrochemical Company Reagent Factory) and FR-32 polymerization inhibitor (purchased from Shanghai Unite Co., Ltd.) were prepared. The mass ratio of the first resin system, methyl ethyl ketone peroxide, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com