Device and method for killing tiny organisms in water body by using hydrodynamic cavitation and strengthened ozone

A hydraulic cavitation and ozone generation technology, which is applied in the field of water treatment, can solve the problems of low ozone utilization rate and achieve the effects of high ozone utilization rate, easy operation, and low investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

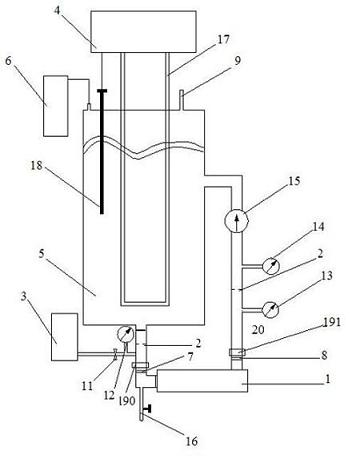

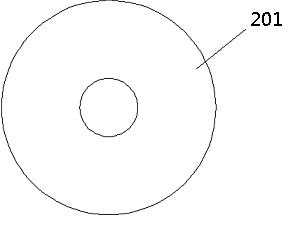

[0032] In this embodiment, a device and method for using hydraulic cavitation and its enhanced ozone to kill tiny organisms in water bodies, the hydraulic cavitation generator 2 contained in it adopts the following methods: figure 2The structural form of the single-hole orifice plate 201, the hole diameter is selected as 12 mm (see Table 1 for parameters), and the material of the water tank 5 is stainless steel. Pour 1.75 L of algae water into the water tank 5 of the hydraulic cavitation device, the initial chlorophyll a and Microcystis aeruginosa algal cell numbers were 30 μg / L, 1.8×10 6 individual / mL. Cycle treatment at 20 °C for 20 minutes, and measure the concentration of chlorophyll a and Microcystis aeruginosa algae cell number after treatment. Under negative pressure (water absorption) hydraulic cavitation conditions, the removal rates of chlorophyll a and Microcystis algae cell numbers were 14.7% and 15.1%, respectively. The treatment time was extended to 60 minutes...

Embodiment 2

[0036] In this embodiment, a device and method for using hydraulic cavitation and its enhanced ozone to kill tiny organisms in water bodies, the hydraulic cavitation generator 2 contained in it adopts the following methods: Figure 4 The structural form of the single-hole orifice plate 203 with a transverse blade, the aperture is 6 mm, and 11 pieces of razor blades are evenly arranged and welded on the hole surface, and the distance between the blades is 0.5mm (see Table 2 for parameters). The orifice plate is installed on the The water inlet end of the circulating water pump 1; the material of the water tank 5 is engineering plastics. Pour 2.5 L of algae water into the water tank of the hydraulic cavitation device, and the number of cells of Microcystis aeruginosa is 3.5×10 6 individual / mL. The algal water was circulated at 25 °C for 20 minutes, and the concentrations of chlorophyll a and Microcystis aeruginosa algal cells after treatment were measured. Under negative press...

Embodiment 3

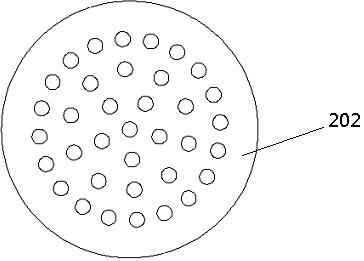

[0039] In this embodiment, a device and method for using hydraulic cavitation and its enhanced ozone to kill tiny organisms in a water body, the hydraulic cavitation generator contained in it adopts such as figure 2 single-hole orifice plate 201 with a pore diameter of 6 mm (see Table 1 for parameters) and image 3 The number of holes is 9, and the hole diameter is 2 mm. The combined structure of the porous orifice plate 202 (see Table 3 for parameters). The distance between the two orifice plates is 30 mm. This combined orifice plate is installed at the water inlet of the circulating water pump 1. Pour 2.5 L of algae water into the water tank 5 of the hydraulic cavitation device, and the number of cells of Microcystis aeruginosa is 3.5×10 6 individual / mL. The algal water was circulated at 25 °C for 20 minutes, and the concentrations of chlorophyll a and Microcystis aeruginosa algal cells after treatment were measured. Under negative pressure (water absorption) hydraulic ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com