Infrared isolated heat-absorption float glass

A float glass, infrared technology, applied in the field of float glass, can solve the problems of difficult glass composition, high melting point, poor heat absorption performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

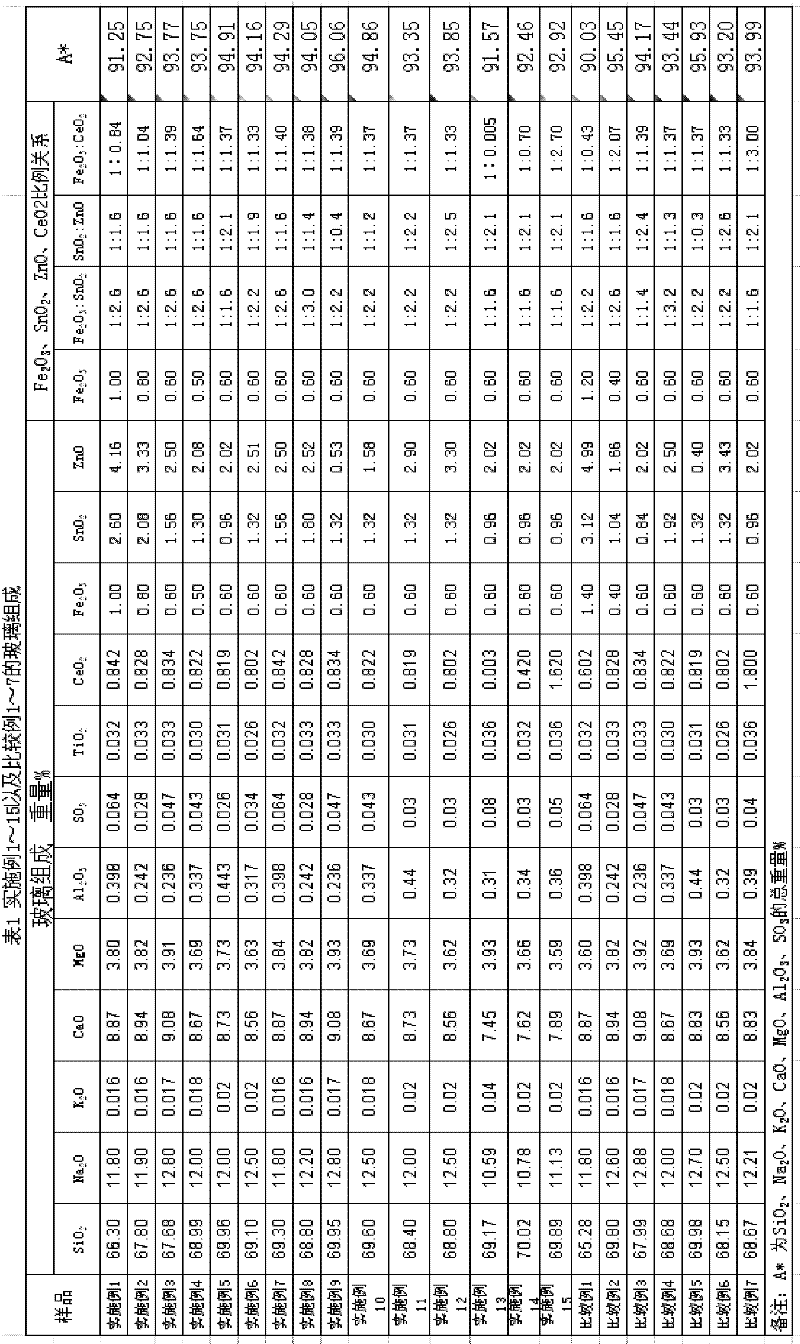

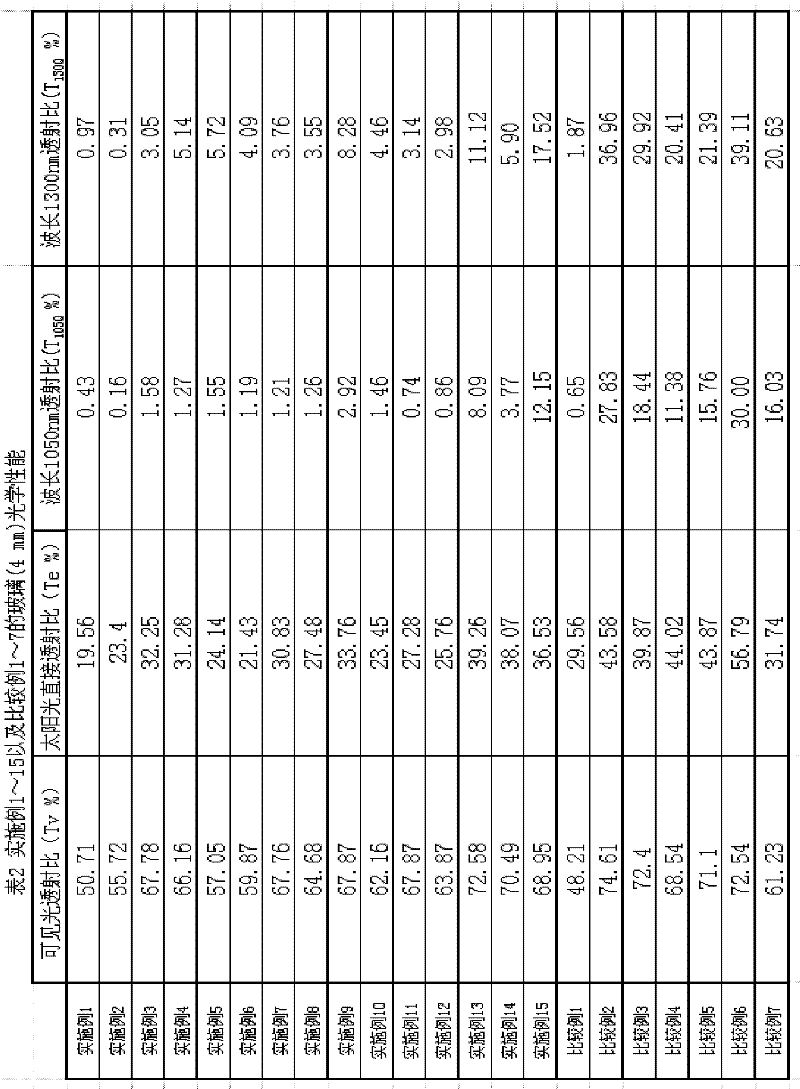

[0015] Embodiment: adopt the general raw material of float glass, such as silica sand, dolomite, limestone, Glauber's salt and other raw materials, 500g of mixed material is melted at 1500 ℃ for 5h, then pour the molten glass into a graphite mold at 1300 ℃, then cut off the power supply, Annealing and cooling to obtain glass with a thickness of 6-10 mm; then grinding and polishing to form a 4 mm thick glass sample for optical performance testing and glass composition testing. The optical performance test is carried out in accordance with the standards of ISO 9050-2003, ISO 13837-2008, and GB T 2680-1994, using the Lambda 950 spectrophotometer equipment of PE Company; the glass composition test is carried out with the Rigaku XRF fluorescence spectrometer equipment. The glass compositions and optical properties of Examples 1-15 and Comparative Examples 1-7 are listed in Table 1 and Table 2, respectively. Fe in glass composition 2 o 3 , SnO 2 , ZnO, CeO 2 The proportional rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com