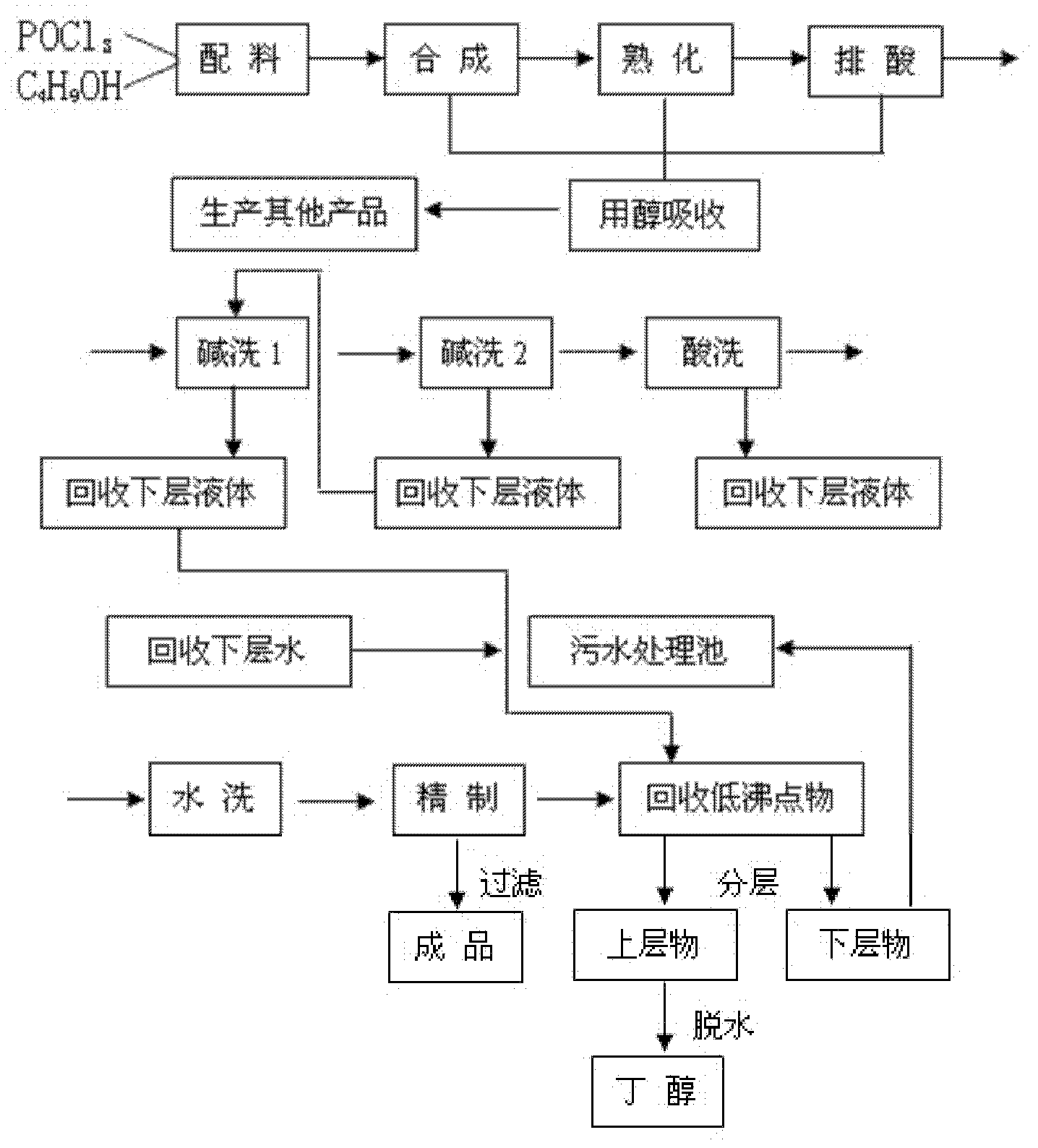

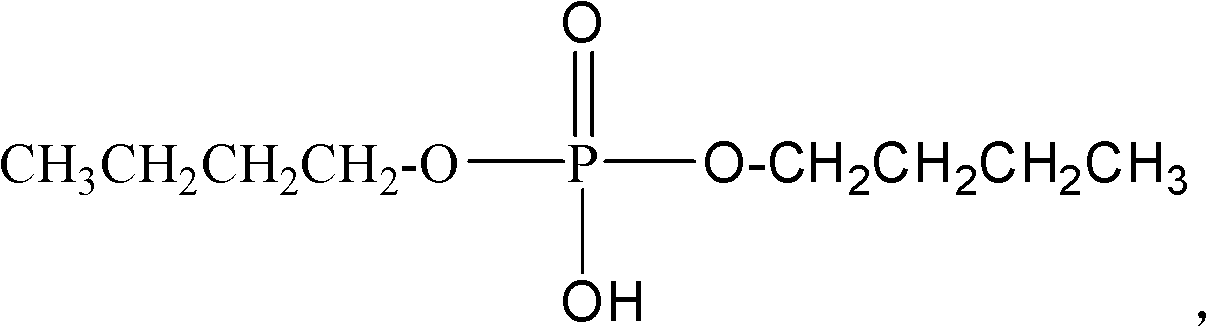

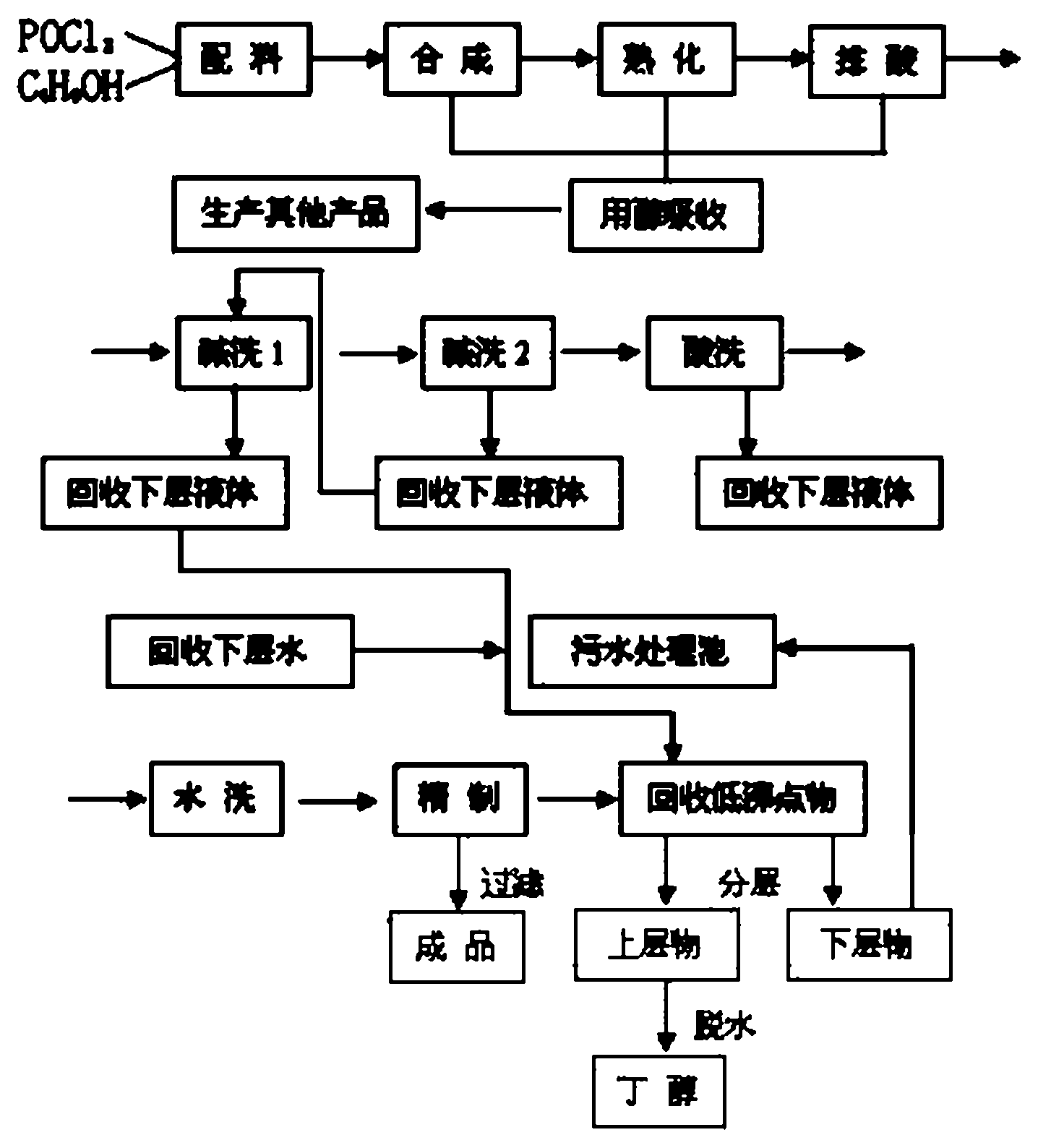

Method for producing dibutyl phosphate by comprehensively using three wastes in production process

A technology of dibutyl phosphate and production process, which is applied in the field of directly producing dibutyl phosphate with alcohol and phosphorus oxychloride, can solve the problems of repetition, waste of water, large energy consumption, etc., so as to save processes and equipment, reduce Water consumption and effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Synthesis: Take 0.90mol of phosphorus oxychloride and place it in a jacketed enamel reaction kettle, pass supercooled water below 0°C in the enamel reaction kettle jacket, and install a 10m 2 Cooling water is passed through the condenser; slowly add 2.20mol n-butanol and stir to keep the temperature of the whole reaction process at 0-10°C; continue stirring for 1 hour after the addition of n-butanol is completed, and keep the temperature at 10°C under normal pressure ;

[0025] (2) Ripening: heat up to raise the temperature of the reaction solution to 30°C, keep stirring at normal pressure for 3 hours, and the HCl gas generated during the ripening process is absorbed by n-butanol through the condenser;

[0026] (3) Acid discharge: heat up to 40°C, pressurize to 80kPa, continue stirring for 3 hours; then heat up to 50°C, vacuumize, the vacuum degree is greater than 18mmHg column, and continue stirring for 3 hours; the HCl gas generated during the acid discharge proce...

Embodiment 2

[0042] (1) Synthesis: Take 1.10mol of phosphorus oxychloride and place it in a jacketed enamel reaction kettle, pass supercooled water below 0°C in the enamel reaction kettle jacket, and install a 10m 2 Cooling water is passed through the condenser; slowly add 2.30mol n-butanol and stir to keep the temperature of the whole reaction process at 0-10°C; continue to stir for 2 hours after the addition of n-butanol is completed, and keep the temperature at 10°C under normal pressure ;

[0043] (2) Ripening: heat up, make the temperature of the reaction solution rise to 25°C, keep the normal pressure and continue to stir for 2h, the HCl gas generated during the ripening process is absorbed by n-butanol through the condenser;

[0044] (3) Acid discharge: raise the temperature to 35°C, pressurize to 75kPa, continue to stir for 2 hours; then raise the temperature to 45°C, evacuate, the vacuum degree is greater than 18mmHg column, and continue to stir for 2 hours; the HCl gas generated ...

Embodiment 3

[0052] (1) Synthesis: Take 1mol of phosphorus oxychloride and place it in a jacketed enamel reaction kettle, pass supercooled water below 0°C in the enamel reaction kettle jacket, and install a 10m 2 Cooling water in the condenser; slowly add 2.3mol n-butanol and stir, keep the temperature of the whole reaction process at 0-10°C; continue stirring for 1 hour after the addition of n-butanol, and keep the temperature at 12°C under normal pressure ;

[0053] (2) Ripening: heat up to raise the temperature of the reaction solution to 30°C, keep stirring at normal pressure for 3 hours, and the HCl gas generated during the ripening process is absorbed by n-butanol through the condenser;

[0054] (3) Acid discharge: heat up to 45°C, pressurize to 85kPa, continue stirring for 3 hours; then heat up to 55°C, vacuumize, the vacuum degree is greater than 18mmHg column, and continue stirring for 3 hours; the HCl gas generated during the acid discharge process is condensed The device is abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com