Direct-current pulsed arc processing system and arc processing method

A technology of arc processing and DC pulse, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of arc breaking, damage to material properties, and insufficient arc supply, etc., and achieve the effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

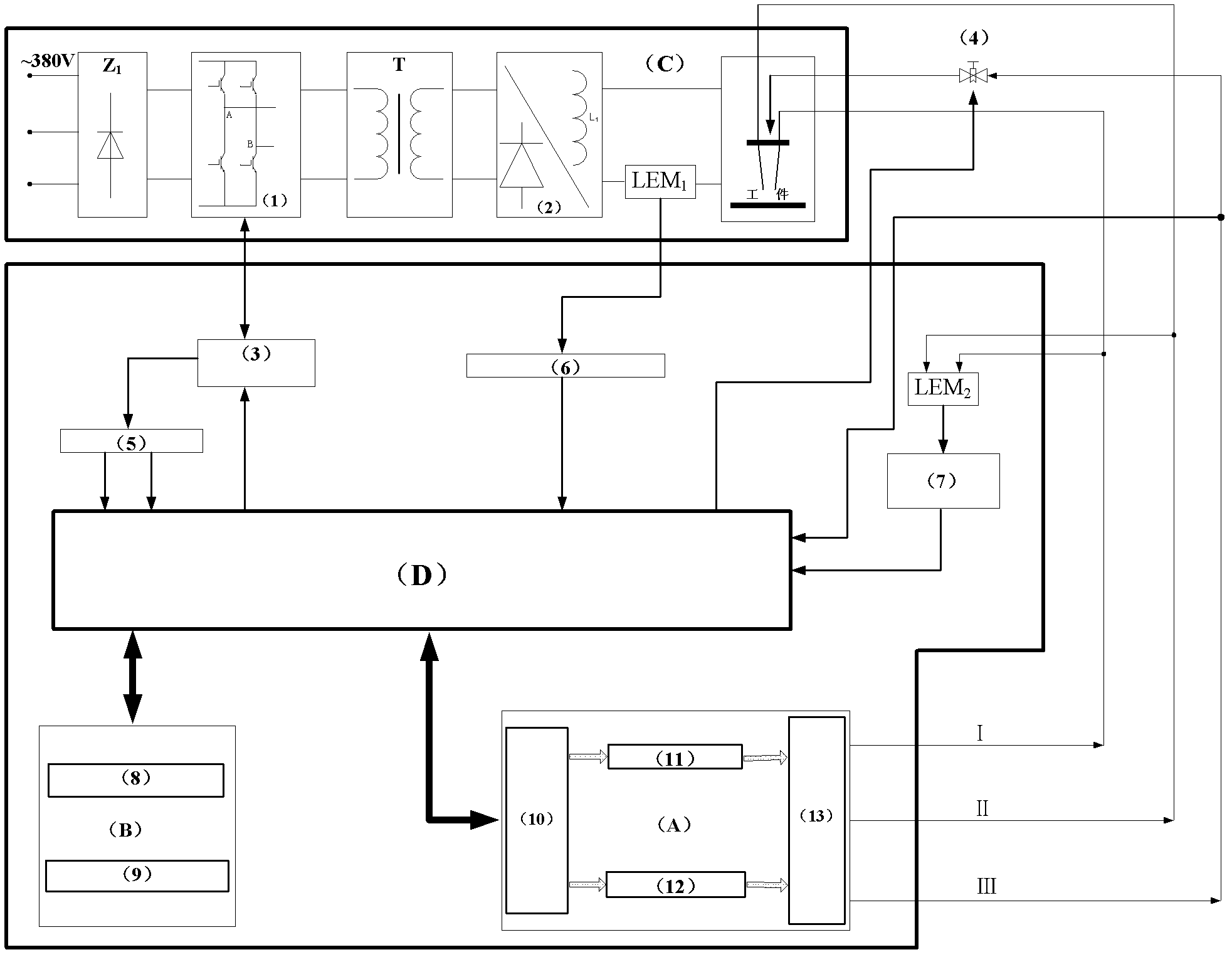

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described;

[0027] The connection relationship as described above is adopted.

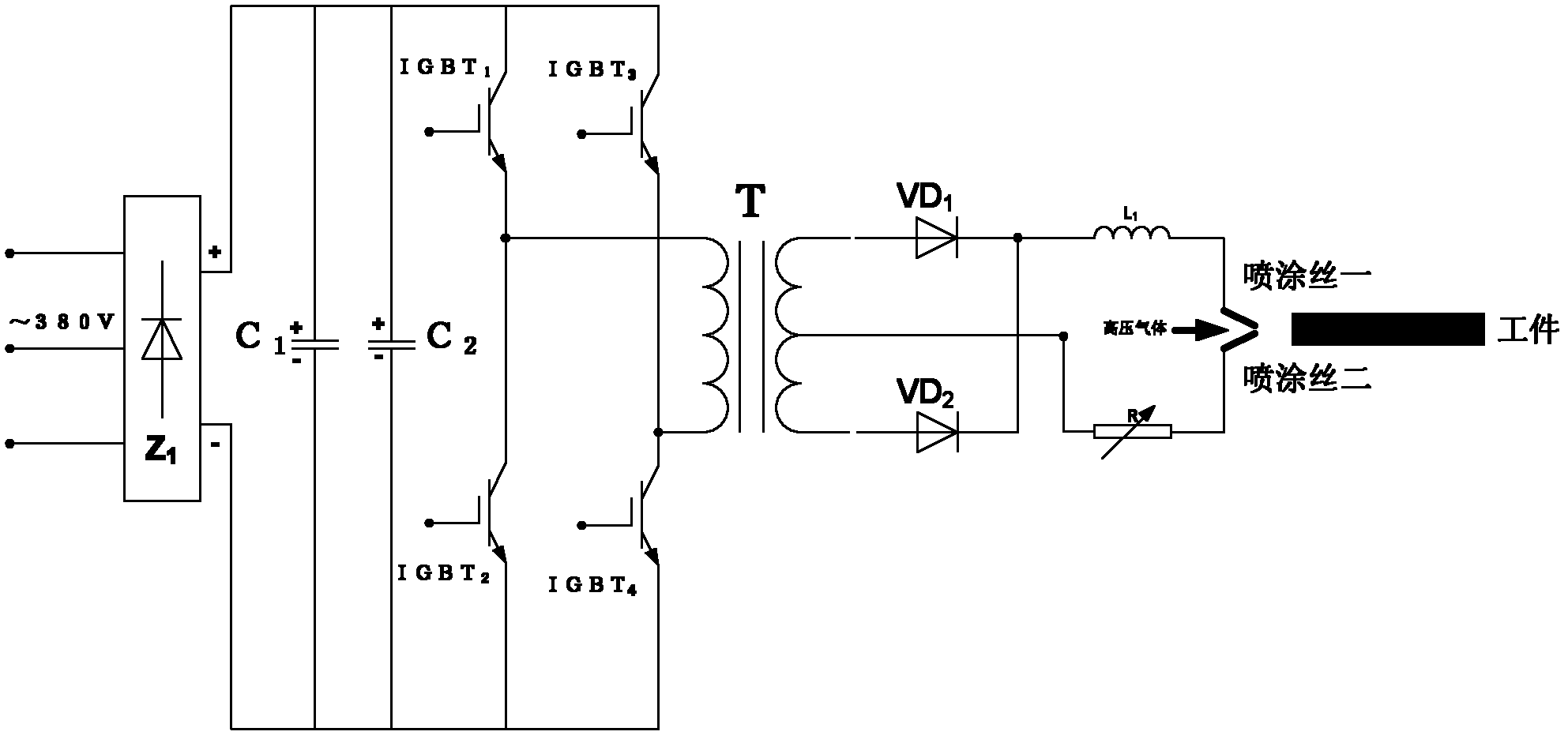

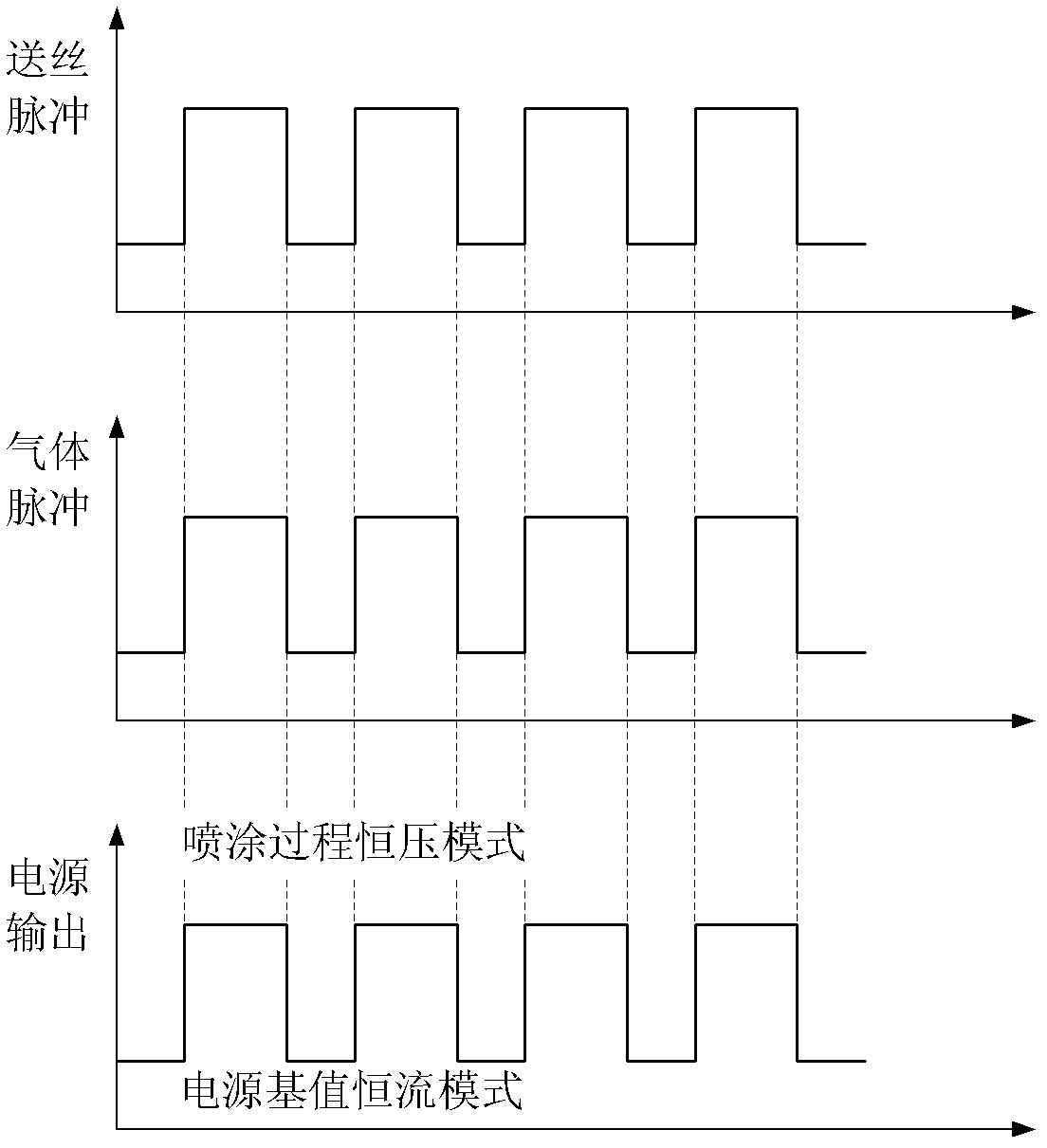

[0028] Such as figure 1 When spraying as shown, the main circuit is connected to 380v three-phase AC voltage. After the rectifier Z1, Z 1 It is composed of four unidirectional rectifier diodes; then it is filtered by filter capacitors C1 and C2 to obtain DC power supply to the full-bridge inverter circuit, which is composed of four IGBT switching devices or related integrated modules; the inverter voltage is output to high frequency The primary side of the transformer T is complex-varied and output to the rectification filter circuit, which is composed of two diodes VD1, VD2, high-frequency inductor L1, current limiting resistor R, and spraying wire 1 and spraying wire 2 as loads; the DSP controller drives circuit, controlling the IGBT 1~4 Medium IGBT 1 、IGBT 4 Simultaneously t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com