Probe of conducting atomic force microscope and measuring methods employing probe

An atomic force microscope and atomic force technology, applied in the measurement of electricity, measurement devices, measurement of electrical variables, etc., can solve the problems of difficult to meet the needs of micro-nano structure detection and limited enhancement effect of the needle tip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A specific embodiment of a probe for a conductive atomic force microscope provided by the present invention and a measurement method using the probe will be described in detail below in conjunction with the accompanying drawings.

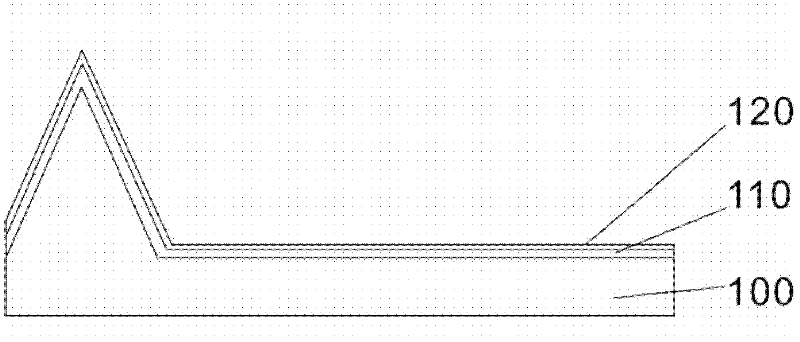

[0011] attached figure 1 Shown is a schematic structural view of the probe of the conductive atomic force microscope according to the specific embodiment of the present invention, including a substrate 100 , a nickel film 110 and a graphene film 120 . The probe can be prepared by plating a nickel film 110 with a thickness of 5-50 nm on the surface of the cantilever probe substrate 100 used in the atomic force microscope by thermal evaporation or magnetron sputtering. This metallization method belongs to the known technology and will not be described in detail here. The nickel film 110 is a catalyst layer for growing graphene on the probe, so its material can also be other metals, and the material of the cantilever probe base can be silicon, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com