Remote I/O (input/output) control system of Modbus fieldbus DI-16-route monitor

A modbus-rtu, field bus technology, applied in the field bus technology and programmable controller PLC, Modbus field bus control field, can solve the problems of enterprise economic loss, technical service can not keep up, poor quality, etc., to achieve accurate and reliable data , The effect of strong anti-interference ability and strong practical range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

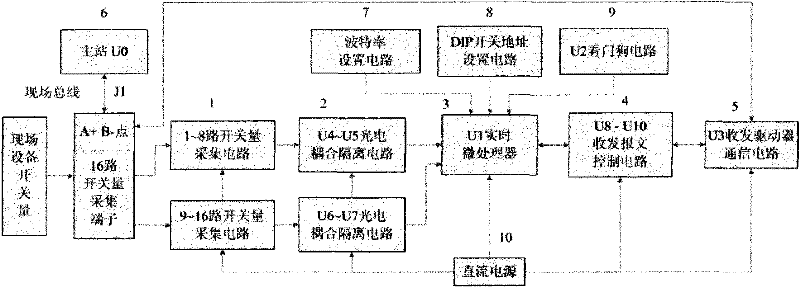

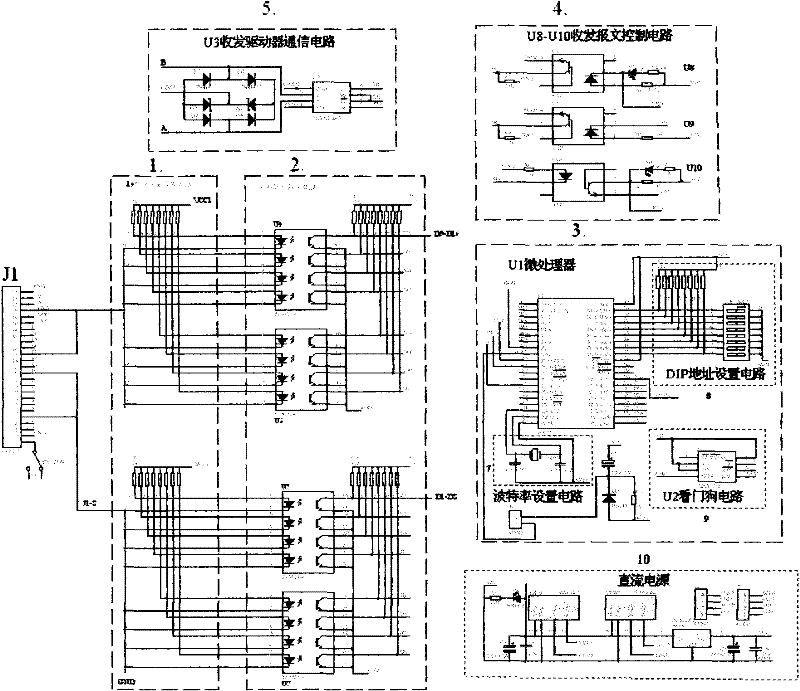

[0065] 1. The master station 6U0 sends a request message frame and the communication message is transferred as follows: the master station (6) U0 sends a request message frame, via field bus A + B - Point J 1Connecting terminal, transceiver driver communication circuit (5), U8-U10 transceiver control circuit (4), slave station (3) U1 microprocessor reads request message frame data.

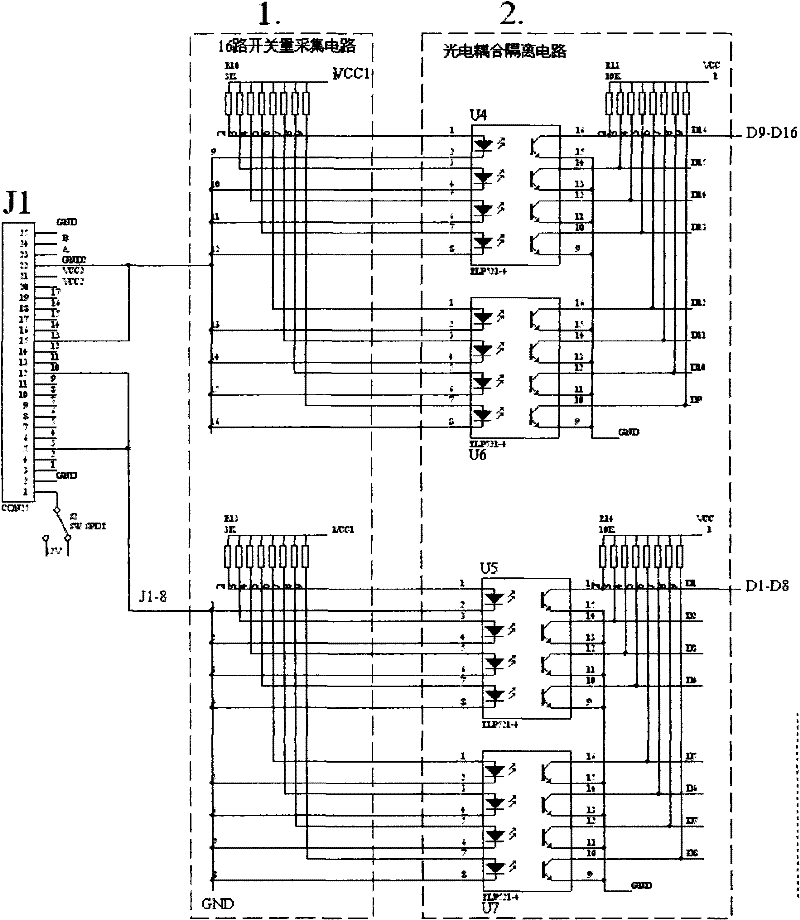

[0066] 2. The communication message transmission of the slave station 3U1 response message frame is: start the U1 microprocessor switching value acquisition subroutine, through 1-8,, 9-16 switching value acquisition circuit (1), U4-U7 photoelectric coupling isolation circuit (2), slave station (3) U1 sends a response message frame, U8-U10 send and receive message control circuit (4), send and receive driver communication circuit (5), A + B - Point J1 connection terminal, enter the main station (6) upper computer U0 through the field bus to read the response message data.

[0067] 3. Modbus mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com