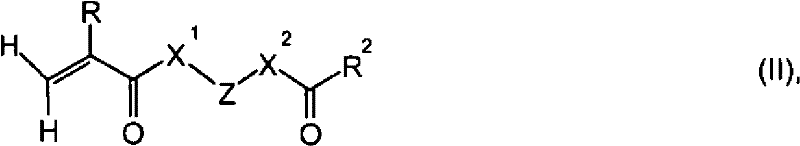

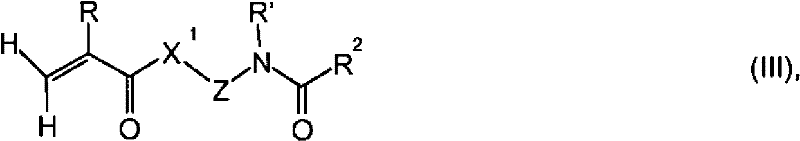

Polyfunctional (meth)acrylic polymer, coating composition, process for producing a coating and coated article

An acrylic and polymer technology used in the preparation of coatings and coated products can solve problems such as increasing brittleness and achieve the effects of high gloss, good water resistance, long-term storage capacity and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] 50.01 g of solvent (Solvesso 100) were initially charged to the reaction vessel and this initial charge was heated to 140°C. Oxygen present in the reaction vessel was removed by introducing nitrogen. Subsequently, a mixture containing 15.33 g of di-tert-butyl peroxide (DTBP), 41.15 g of isobornyl methacrylate (IBOMA), 61.73 g of hydroxyethyl methacrylate (HEMA), 20.58 g of methacrylic acid was added over a period of 4 hours. Reaction mixture of ethylhexyl ester (EHMA), 20.58 g methacryloxy-2-ethyl-fatty acid amide (MUMA), 61.73 g styrene and 3.69 g 2-mercaptoethanol. The reaction was then continued for 30 minutes with stirring. The mixture was then cooled to 80°C. To complete the reaction, a mixture comprising 0.21 g of di-tert-butyl peroxide (DTBP) and 15 g of solvent (Solvesso 100) was added, followed by stirring at 80° C. for a further 2 hours. Subsequently, stirring was continued for a further 30 minutes without heating.

[0174] The polymer content was adjusted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com