System for cleaning surface of strip steel through hot-water circulation

A technology of hot water circulation and cleaning belt, applied in workpiece surface treatment equipment, metal processing equipment, metal rolling and other directions, can solve the problems of high cost and high maintenance requirements, and achieve the effect of supplementing heat energy loss, easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

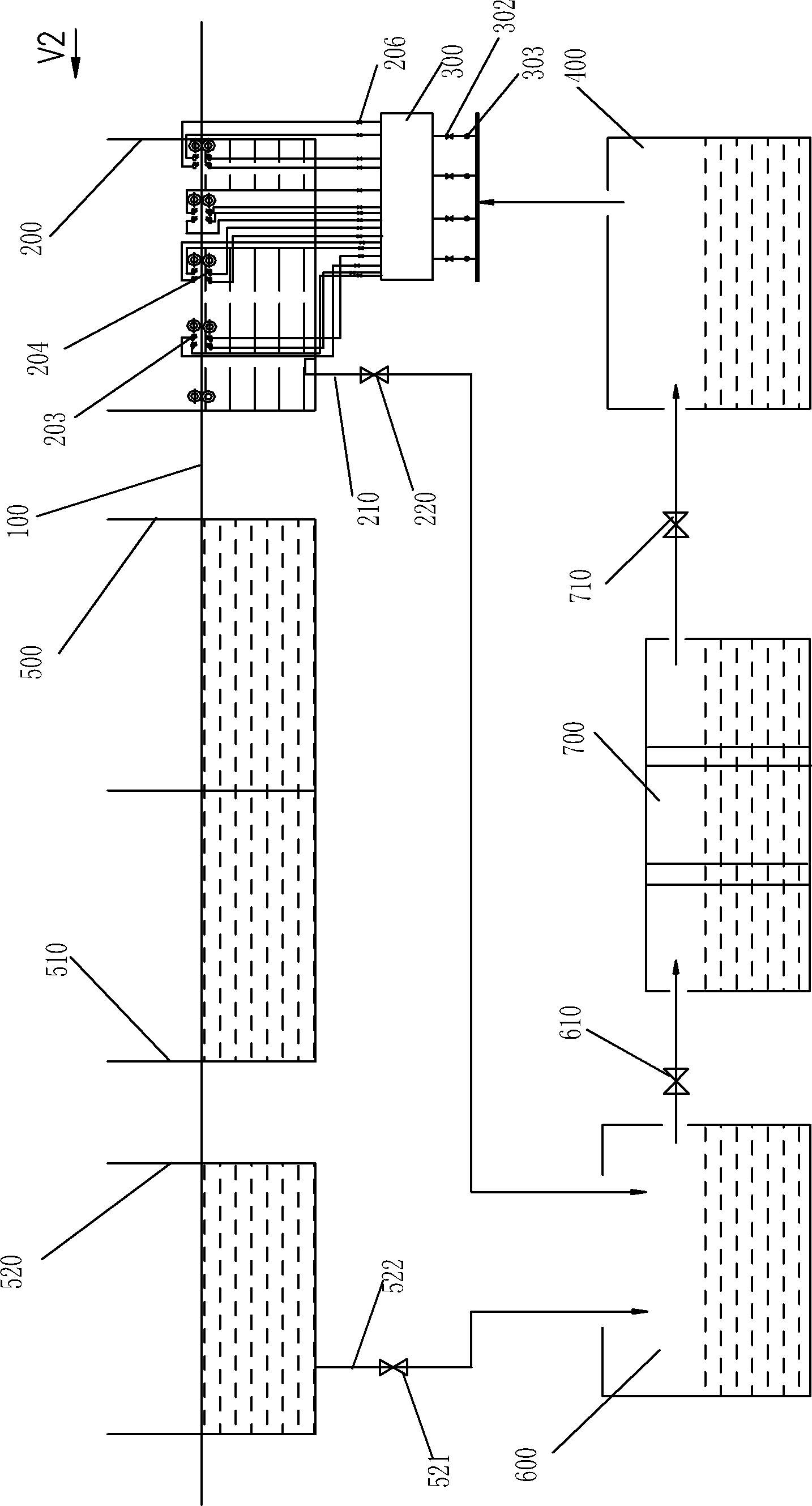

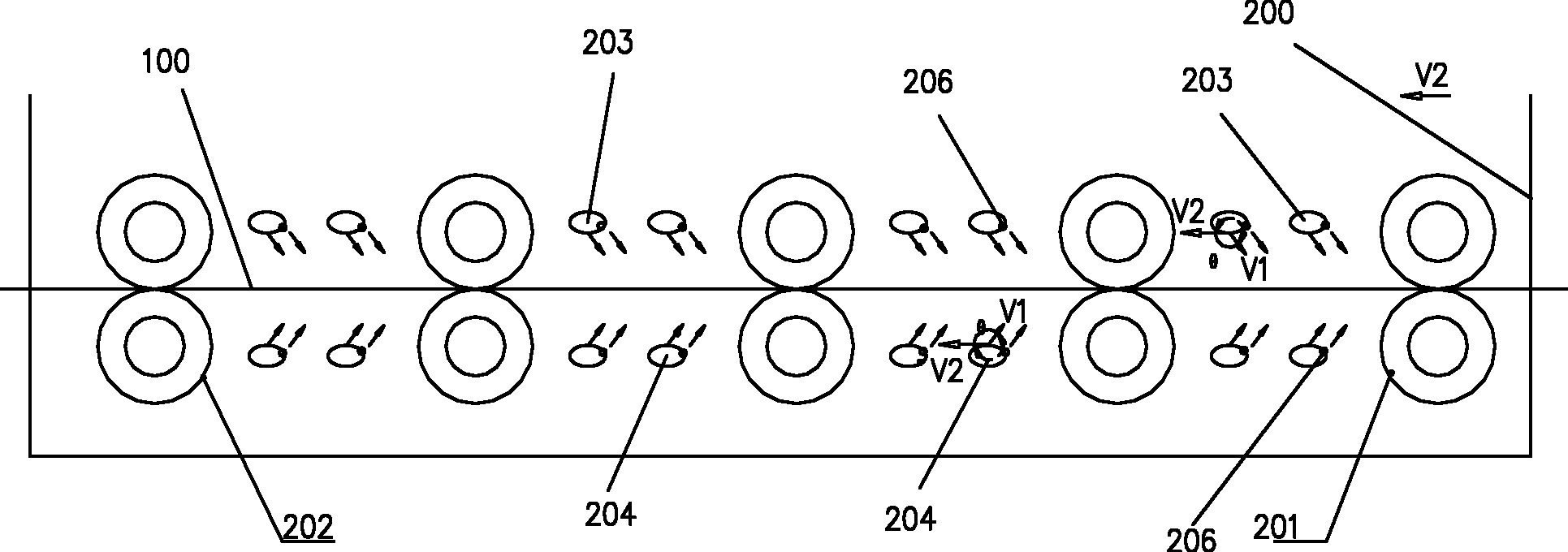

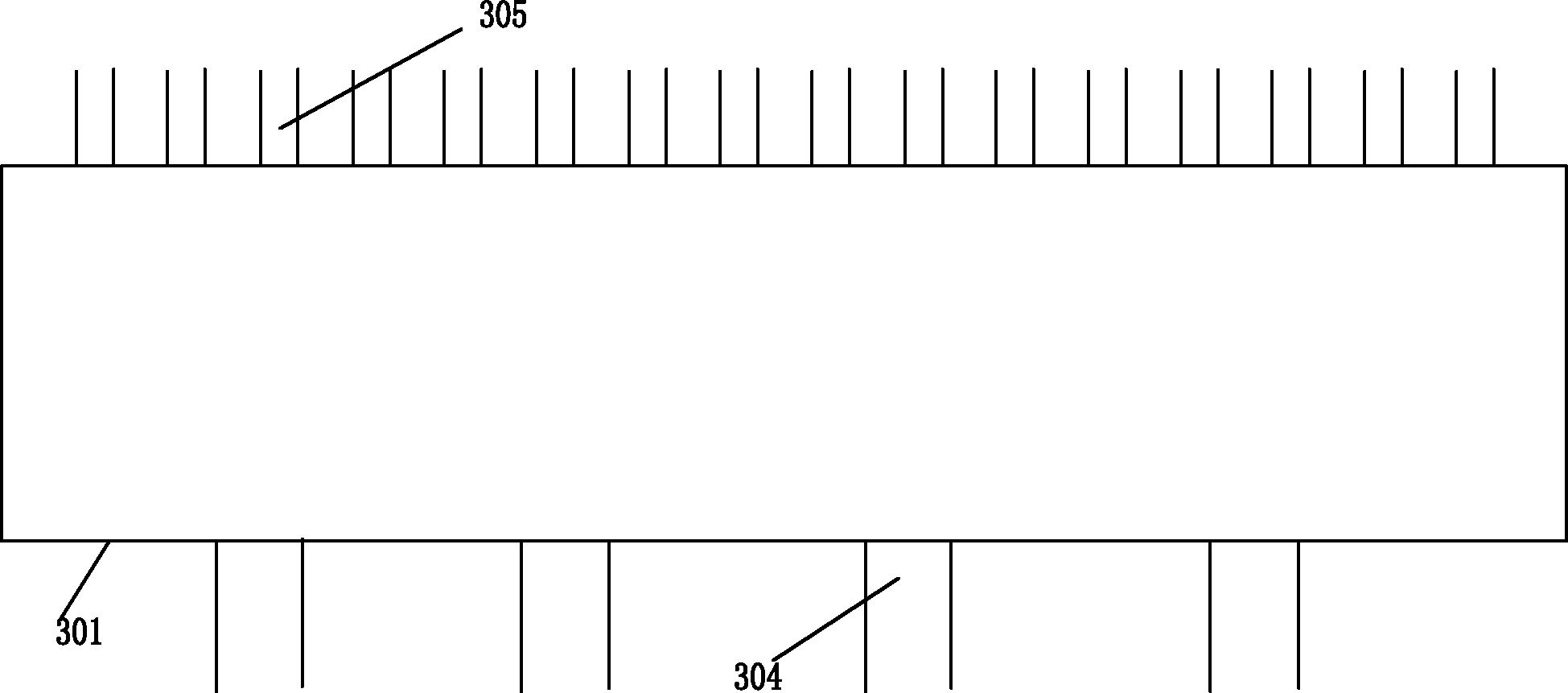

[0023] like figure 1 Shown, illustrate with the cleaning process of strip steel 100 systems; The strip steel surface high-pressure hot water spray tank 200 is provided with upper water spray pipe 203 and lower water spray pipe 204, strip steel guide roller 203, upper water spray pipe and The lower water spray pipe is connected to the outlet pipe of the pressure-stabilizing pressure storage tank 300 through a pipeline, and the water inlet pipe of the pressure-stabilizing pressure storage tank 300 passes through the water supply pump 303, and the water supply pump 303 is connected to the water storage tank 400 through a pipeline.

[0024] The process after the steel strip 100 is sprayed with high-pressure hot water is alkali scrubbing, that is, the alkali liquid pre-cleaning tank 500 in the system; The structures of the alkaline solution pre-cleaning tank 500 and the electrolytic degreasing tank 510 are prior art, and will not be repeated. In the present invention, due to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com