Machining method for solid carbide reamer

A solid carbide and carbide technology, applied in the field of solid carbide reamer processing, can solve the problems of large material loss, the inability to guarantee the high-precision size, and the wear of the margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

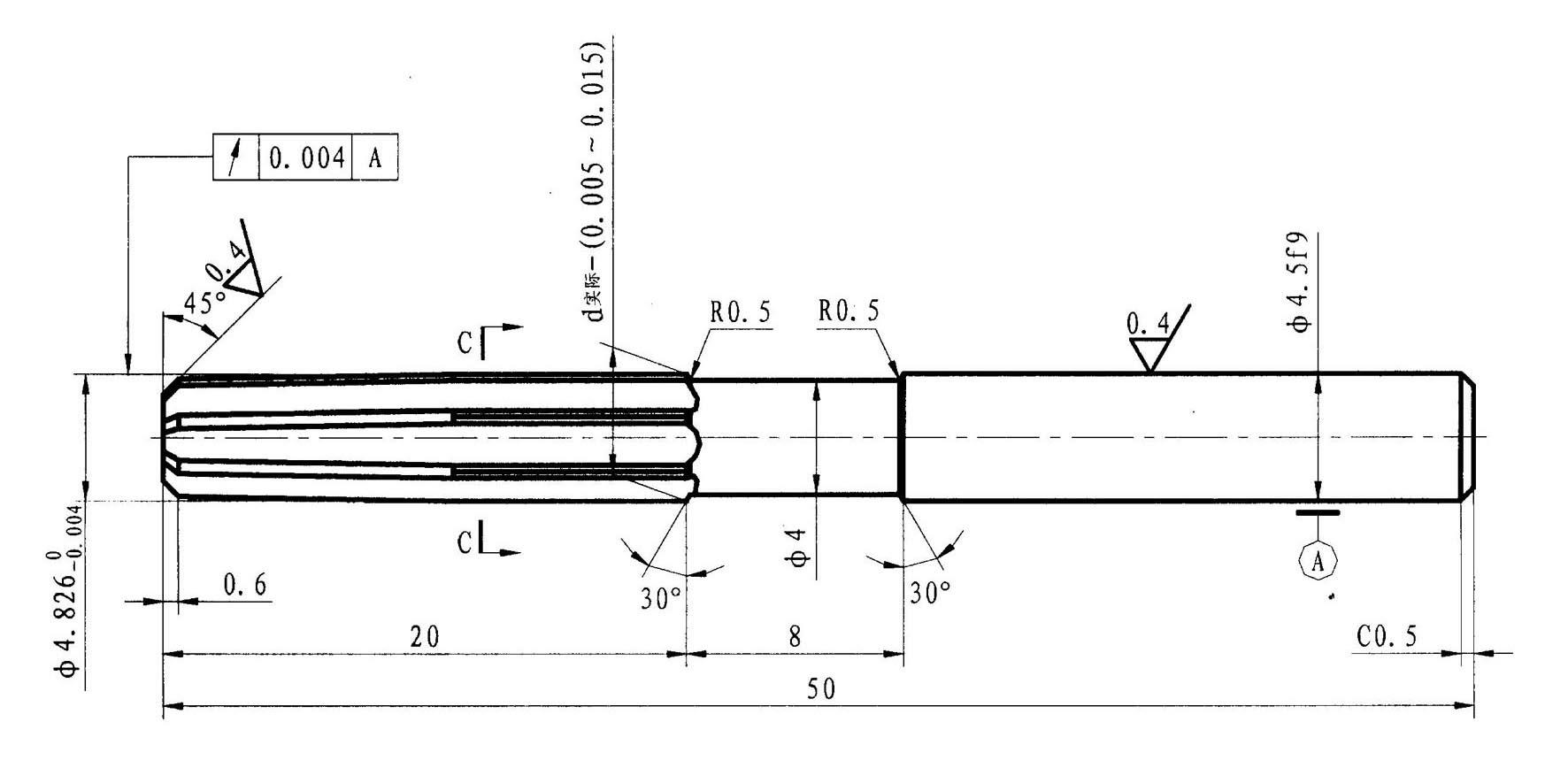

[0016] Such as figure 1 As shown, the processing material is a solid carbide reamer made of Y300 solid carbide bar. The coaxiality and edge accuracy of the reamer are both 0.004mm. The processing method includes the following steps:

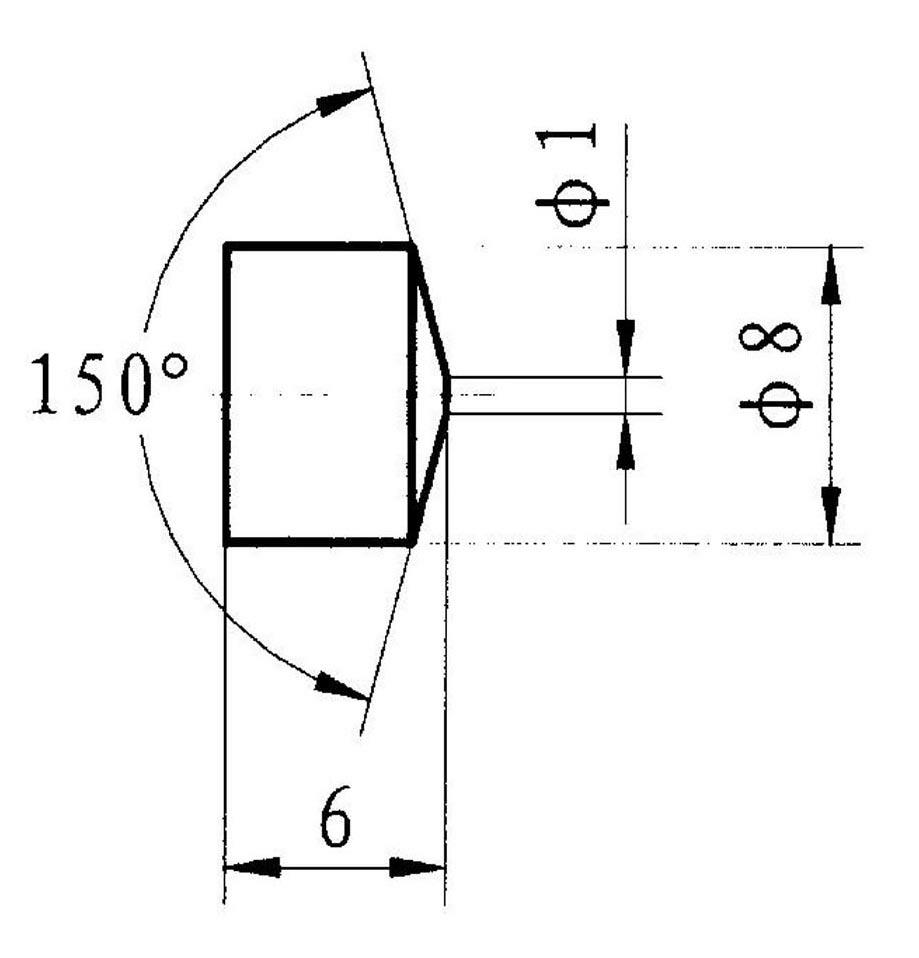

[0017] 1) if figure 2 As shown, the processing of carbon steel false tip: one end of the false tip is cylindrical, and the diameter of the cylinder is larger than the diameter of the outer circle of the carbide reamer to be processed. The top diameter of the trapezoidal truncated circular plane is Ф1;

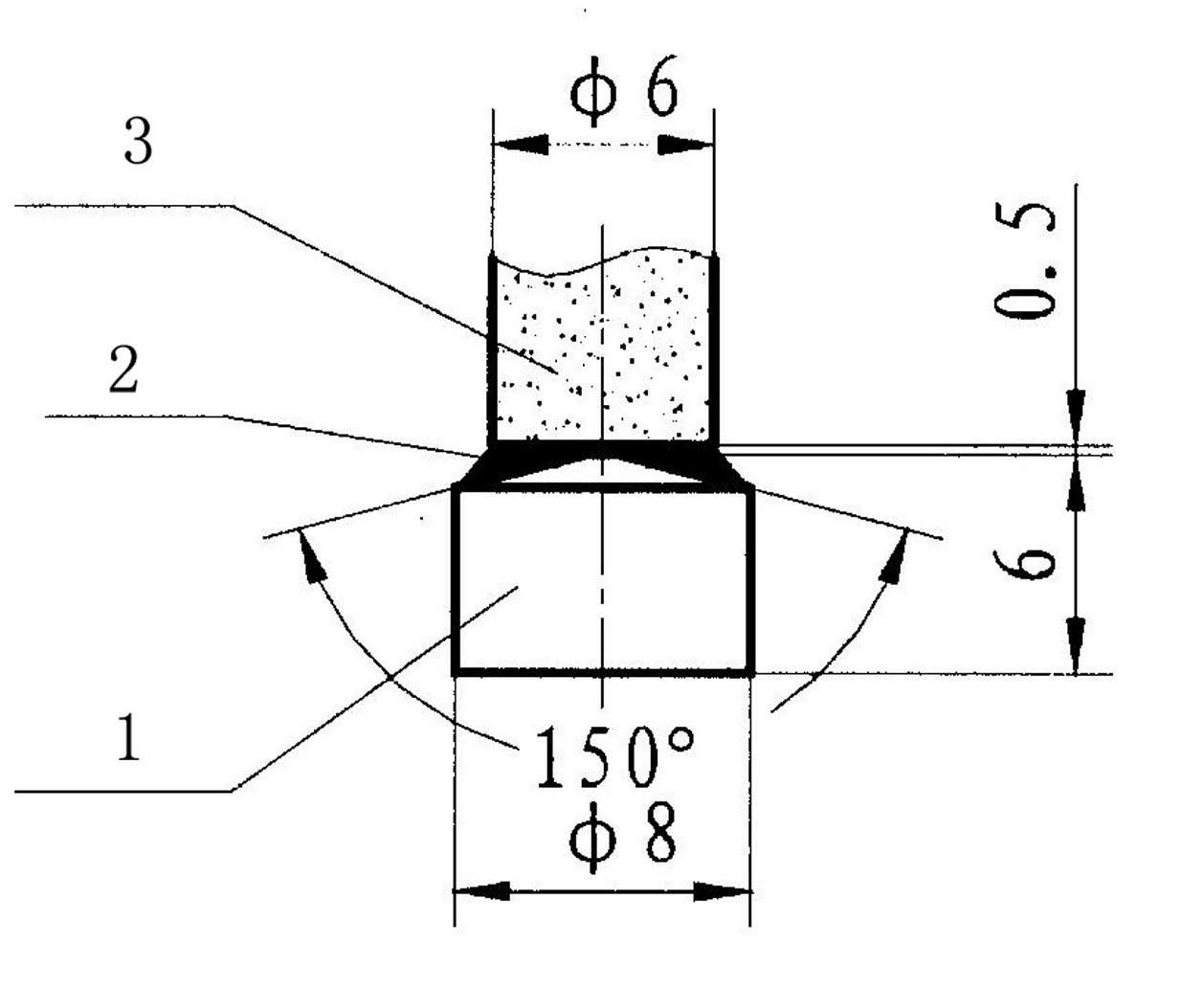

[0018] 2) if image 3 As shown, welding false tip: place the cylindrical surface of the processed false tip downwards, the bottom surface of the carbide bar coincides with the circular plane of Ф1 and is coaxial, and welds the cemented carbide bar and the false tip with copper solder;

[0019] 3) if Figure 4 As shown, turning the false top: use a lathe to turn the false top to a size smaller than the outer diameter of the finished reamer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com