Mine hoist fault diagnosis method and system based on expert system

A fault diagnosis system and mine hoist technology, applied in elevators, transportation and packaging, etc., can solve problems such as single function and difficulty in finding faults, and achieve the effects of simple programming, good real-time performance, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

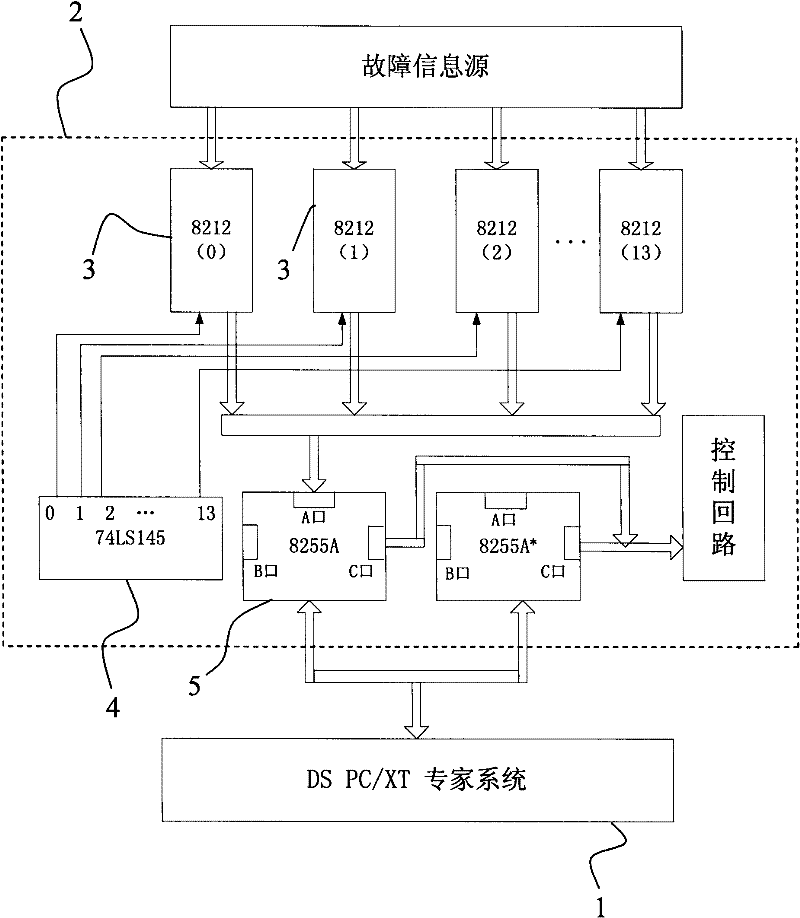

[0041] See figure 1 , which is a structural diagram of an embodiment of the mine hoist fault diagnosis system based on the expert system of the present invention, which includes a knowledge base 1 and an inference engine 2, the knowledge base 1 is used to store fault information and corresponding action signals, and the inference engine 2 It is used to compare the collected real-time working status information of the DC motor with the information in the knowledge base 1, and to determine whether the hoist is faulty. The inference engine 2 further includes fourteen general interface chips 3, decoders 4 and programmable interface chips 5, the fourteen general interface chips 3 are all connected to fault information sources, and the decoder 4 is connected to fourteen general interface chips respectively. The chip 3 is connected, and the programmable interface chip 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com