Method for preparing CuWCr composite material in consumable electrode arc-melting furnace

An electric arc melting furnace and composite material technology, which is applied in the field of CuWCr composite materials prepared by consumable electrode arc melting furnace, can solve the problems of Cr particles not being refined, low voltage resistance strength, high gas content, etc., and achieve high density, The effect of high withstand voltage strength and low gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, 20% of Cu powder, 12% of W powder, and 68% of Cr powder were mixed in a mixer for 3 hours according to mass percentage, and the mixed powder was molded at 400 MPa.

[0024] Then, the compacted blank is placed in a vacuum sintering furnace, and when the vacuum degree is greater than 10 -2 The temperature was raised to 950° C. under a vacuum environment of Pa, and sintered for 150 minutes to obtain a CuWCr sintered compact.

[0025] Finally, the CuWCr sintered compact is placed in a vacuum consumable electrode arc melting furnace, and the vacuum degree is not less than 10 -3 Under the vacuum environment of Pa, adjust the smelting current to be greater than 1500A for smelting, so that the CuWCr blank is melted and dropped into the water-cooled copper crucible under the high temperature of the arc, and taken out after cooling to obtain the CuWCr composite material.

Embodiment 2

[0027] First, 30% of Cu powder, 8% of W powder, and 62% of Cr powder were mixed in a mixer for 5 hours according to the mass percentage, and the mixed powder was subjected to cold isostatic pressing at 260 MPa.

[0028] Then, the compacted blank is placed in a vacuum sintering furnace, and when the vacuum degree is greater than 10 -2 The temperature was raised to 1050° C. under a vacuum environment of Pa, and sintered for 60 minutes to obtain a CuWCr sintered compact.

[0029] Finally, the CuWCr sintered compact is placed in a vacuum consumable electrode arc melting furnace, and the vacuum degree is not less than 10 -3 Under the vacuum environment of Pa, adjust the smelting current to be greater than 1500A for smelting, so that the CuWCr blank is melted and dropped into the water-cooled copper crucible under the high temperature of the arc, and taken out after cooling to obtain the CuWCr composite material.

Embodiment 3

[0031] Firstly, 35% of Cu powder, 5% of W powder and 60% of Cr powder were mixed in a mixer for 6 hours according to mass percentage, and then the mixed powder was molded at 400MPa.

[0032] Then, the compacted blank is placed in a vacuum sintering furnace, and when the vacuum degree is greater than 10 -2 The temperature was raised to 1000° C. under a vacuum environment of Pa, and sintered for 100 minutes to obtain a CuWCr sintered compact.

[0033] Finally, the CuWCr sintered compact is placed in a vacuum consumable electrode arc melting furnace, and the vacuum degree is not less than 10 -3 Under the vacuum environment of Pa, adjust the smelting current to be greater than 1500A for smelting, so that the CuWCr blank is melted and dropped into the water-cooled copper crucible under the high temperature of the arc, and taken out after cooling to obtain the CuWCr composite material.

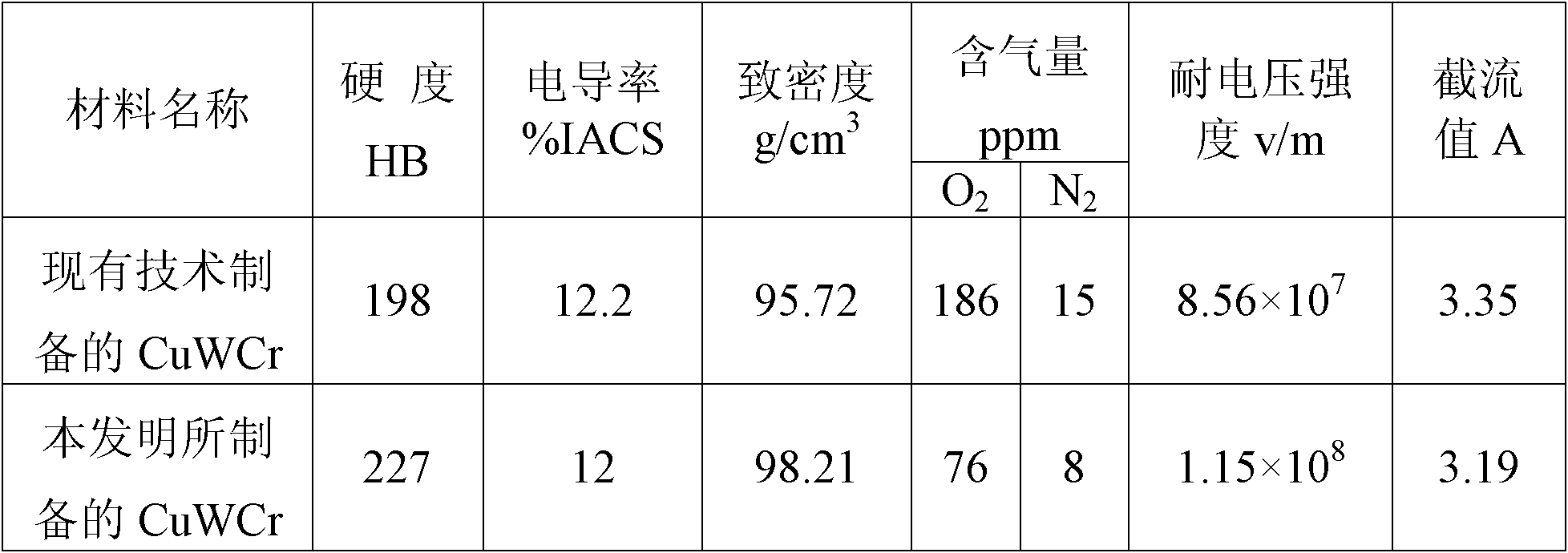

[0034] The performance comparison between the CuWCr composite material prepared by the method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com