Epoxy resin pouring dry type transformer

A dry-type transformer and epoxy resin technology, applied in the field of transformers, can solve problems such as deformation, poor thermal conductivity of epoxy resin, and high brittleness of epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

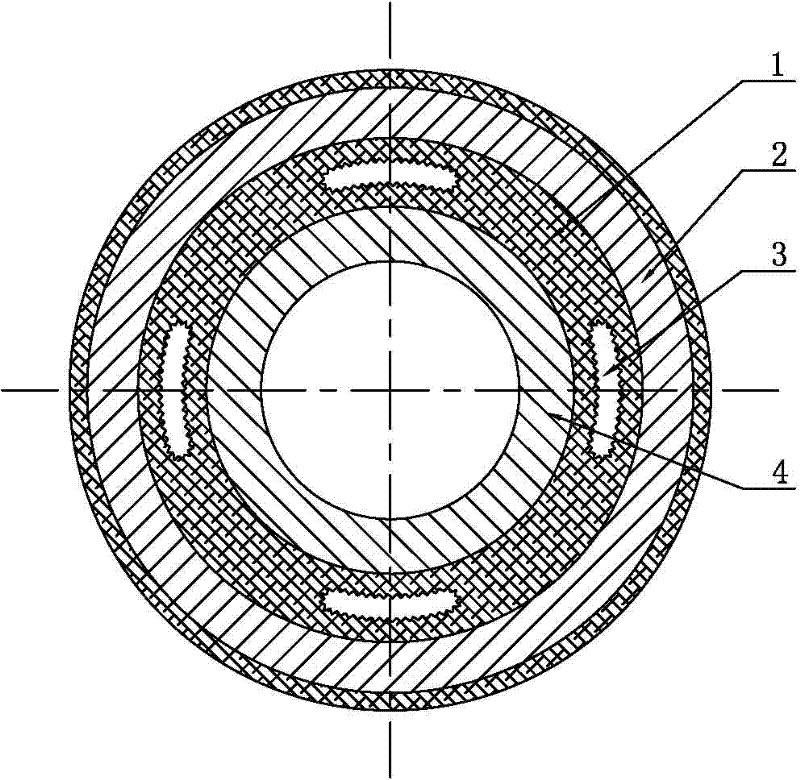

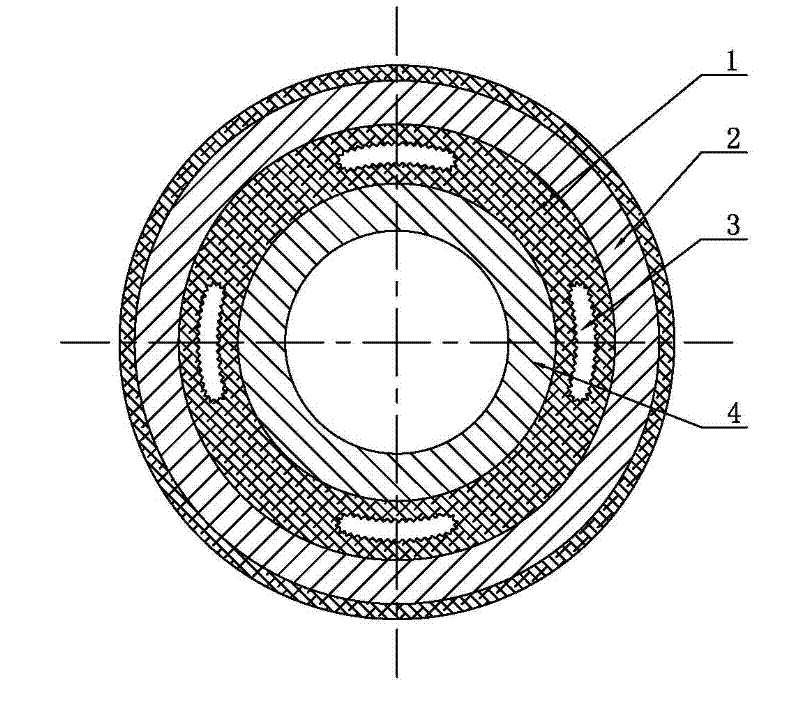

[0017] Such as figure 1 As shown, it is an epoxy resin casting dry-type transformer, which includes a high-voltage coil 2 and a low-voltage coil 4 arranged coaxially. The low-voltage coil 4 is located inside the high-voltage coil 2. In the epoxy resin insulating layer 1, a cooling air channel 3 is arranged between the high voltage coil and the low voltage coil in the epoxy resin insulating layer, and the inner surface of the cooling air channel 3 is zigzag.

[0018] The formulation of the epoxy resin insulation layer includes the following components:

[0019] Bisphenol A type epoxy resin, epoxy value 0.40--, dosage 10Kg;

[0020] Aluminum nitride powder with a particle size of 40-50nm, the dosage is 0.2kg;

[0021] Quartz sand with a particle size of 10-30 mesh, the dosage is 1.5kg;

[0022] Quartz sand with a particle size of 100-150 mesh, the dosage is 1kg;

[0023] Mica powder with a particle size of 200-300 mesh, dosage 1kg;

[0024] Polyamide curing agent 650, dosag...

Embodiment 2

[0034] An epoxy resin casting dry-type transformer, comprising a high-voltage coil and a low-voltage coil arranged coaxially, the low-voltage coil is located inside the high-voltage coil, and the high-voltage coil and the low-voltage coil are integrally arranged in a cast epoxy resin insulating layer, and the ring A cooling air passage is arranged between the high-voltage coil and the low-voltage coil in the epoxy resin insulating layer, and the inner surface of the cooling air passage is zigzag.

[0035] The formulation of the epoxy resin insulating layer includes the following components: bisphenol A epoxy resin, epoxy value 0.55--, dosage 10Kg; particle size 70-80nm aluminum nitride powder, dosage 1kg; particle size 10-30 mesh Quartz sand, dosage 3kg; particle size 100-150 mesh quartz sand, dosage 2kg; particle size 200-300 mesh mica powder, dosage 2.5kg; polyamide curing agent 650, dosage 12kg; ), dosage 1kg.

Embodiment 3

[0037] An epoxy resin casting dry-type transformer, comprising a high-voltage coil and a low-voltage coil arranged coaxially, the low-voltage coil is located inside the high-voltage coil, and the high-voltage coil and the low-voltage coil are integrally arranged in a cast epoxy resin insulating layer, and the ring A cooling air passage is arranged between the high-voltage coil and the low-voltage coil in the epoxy resin insulating layer, and the inner surface of the cooling air passage is zigzag.

[0038] The formulation of the epoxy resin insulation layer includes the following components: bisphenol A epoxy resin, epoxy value 0.55--, dosage 10Kg; particle size 50-70nm aluminum nitride powder, dosage 0.5kg; particle size 10-30 Purpose quartz sand, dosage 2kg; particle size 100-150 mesh quartz sand, dosage 1.5kg; particle size 200-300 mesh mica powder, dosage 1.5kg; dimer acid-based polyamide curing agent, dosage 10kg; hydroxyl-terminated nitrile rubber , dosage 0.8kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com