Fabric film coating agent and preparation method as well as use method thereof

A coating agent and fabric technology, applied in the field of fabric coating agent and its preparation, can solve the problems of inapplicability, complicated preparation process and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

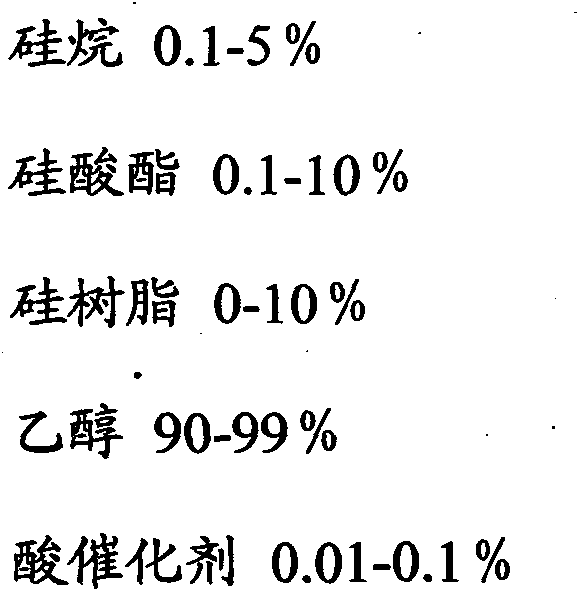

Embodiment 1

[0033] Weigh 0.03g of concentrated sulfuric acid, 0.4g of deionized water and 2g of ethyl orthosilicate into 10g of ethanol, raise the temperature to 50°C, and react for 1 hour; then add 1g of dodecyltriethoxysilane and 0.5g of Hydroxyfluorosilicone resin, reflux at 70°C for 0.5 hour, after cooling, add 90g of ethanol to dilute to prepare fabric coating agent.

[0034] Instructions:

[0035] Firstly, the floating dust on the fabric is cleaned and kept dry, and then the fabric coating agent prepared in this example is evenly sprayed on the surface of the fabric. After standing at room temperature for 30 minutes, the fabric has the effect of waterproof and antifouling.

Embodiment 2

[0037] Weigh 0.08g of concentrated hydrochloric acid (37%), 1g of deionized water, 0.3g of ethyl orthosilicate and 1.5g of methyl orthosilicate and add them to 20g of ethanol, raise the temperature to 50°C, and react for 1.5 hours; then add 0.5 g heptadecafluorodecyltriethoxysilane and 0.2g hydroxyfluorosilicone resin, reflux at 70°C for 0.5 hour, after cooling, add 80g ethanol for dilution to prepare fabric coating agent.

[0038] Instructions:

[0039] First, clean the floating dust on the fabric and keep it dry, then evenly spray the fabric coating agent prepared in this example on the surface of the fabric, and evenly heat it with a hair dryer for 5 minutes, and the fabric will have the effect of waterproof and antifouling.

Embodiment 3

[0041] Weigh 0.03g of concentrated hydrochloric acid (37%), 0.05g of glacial acetic acid, 2g of deionized water and 2g of propyl orthosilicate into 10g of ethanol, heat up to 50°C, and react for 1 hour; then add 0.8g of tridecafluoro Octyltriethoxysilane and 0.5g of hydroxyfluorosilicone resin were refluxed at 70°C for 1 hour, and after cooling, 85g of ethanol was added for dilution to obtain a fabric coating agent.

[0042] Instructions:

[0043] Firstly, the floating dust on the fabric is cleaned and kept dry, and then the fabric coating agent prepared in this example is evenly sprayed on the surface of the fabric. After standing at room temperature for 40 minutes, the fabric has the effect of waterproof and antifouling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com