Temperature equalizing controller

A controller and balanced technology, applied in the direction of temperature control, self-adaptive control, general control system, etc. using electric mode, it can solve the problem that PID controller is difficult to obtain satisfactory control effect, achieve optimal control, and facilitate remote transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

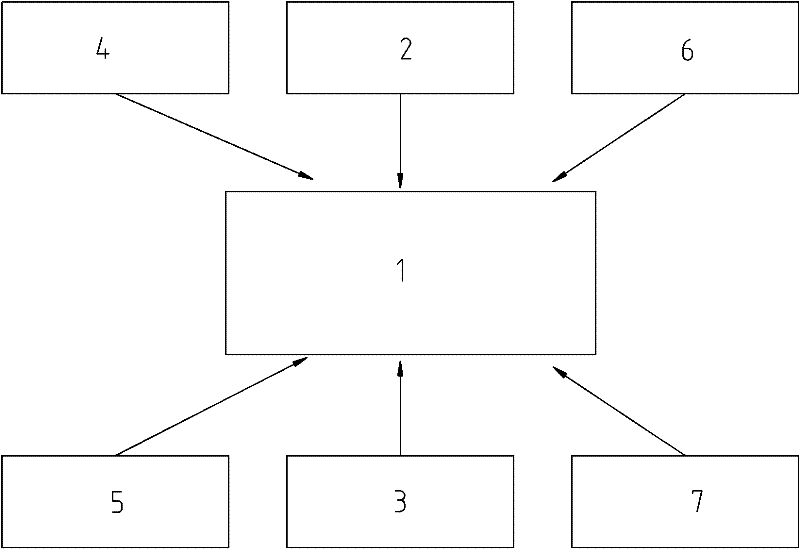

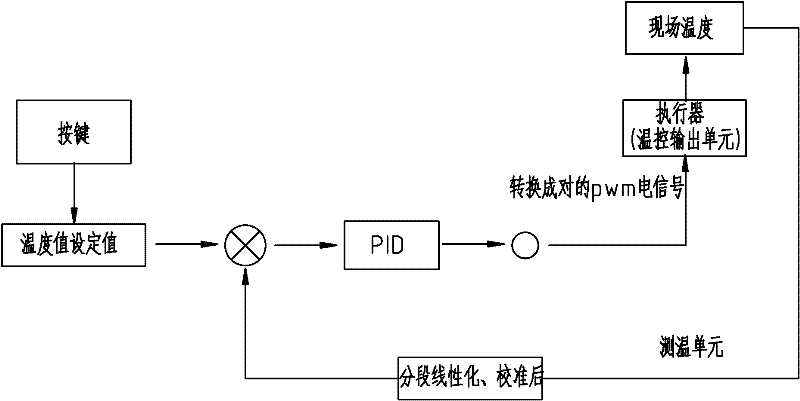

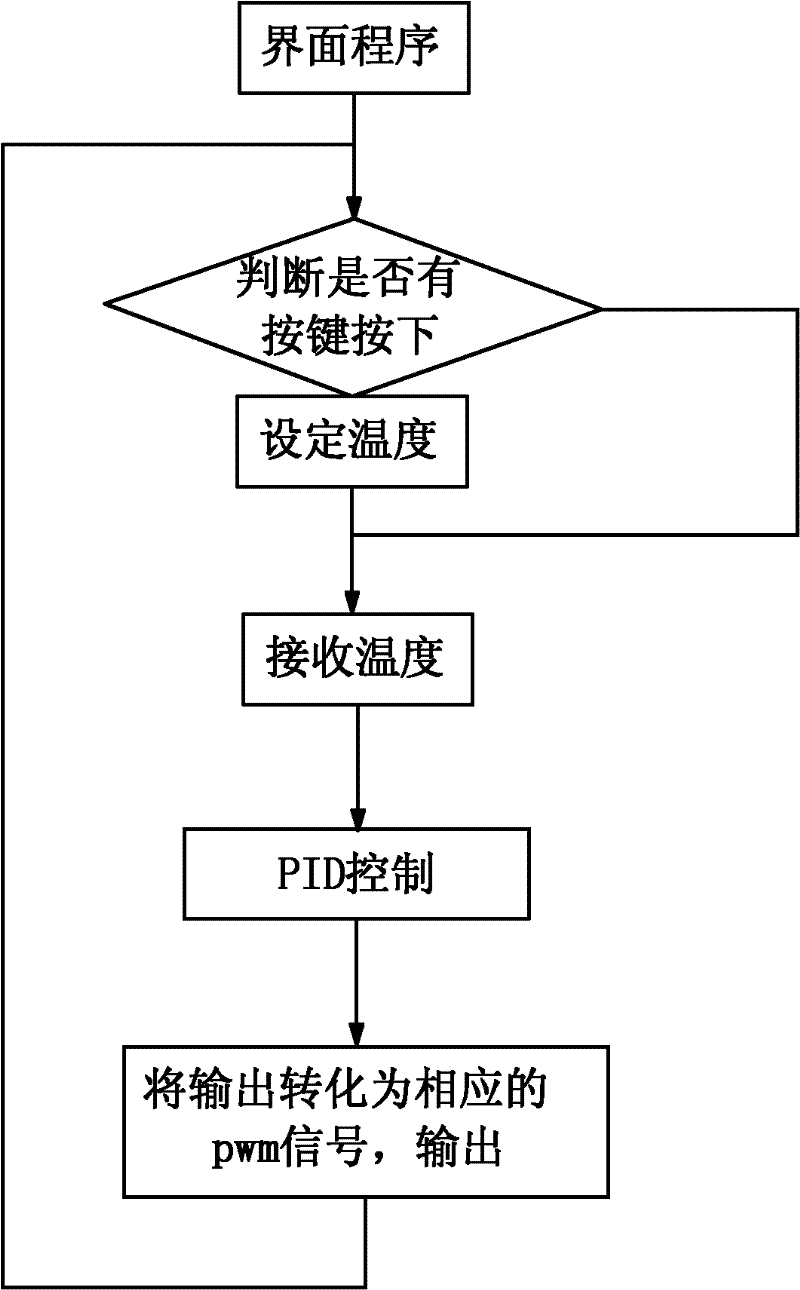

[0018] combine figure 1 , figure 2 and image 3 , a temperature equalization controller, comprising a single-chip microcomputer 1, a temperature measurement unit 2, a temperature control output unit 3 and a key-type input unit 4; the above-mentioned temperature measurement unit, temperature-control output unit and key-type input unit are all connected to the single-chip microcomputer. The temperature value input by the above-mentioned key-type input unit is used as the temperature setting value, and the on-site temperature value measured in real time by the temperature measuring unit is used as the temperature feedback value, and PID control is introduced, according to the temperature error signal between the temperature setting value and the temperature feedback value After obtaining the PID parameters, the single-chip microcomputer makes corresponding control signals according to the PID parameters, and controls the on-site temperature through the temperature control outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com