A Secondary-side Phase Shift Controlled Full-Bridge Converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

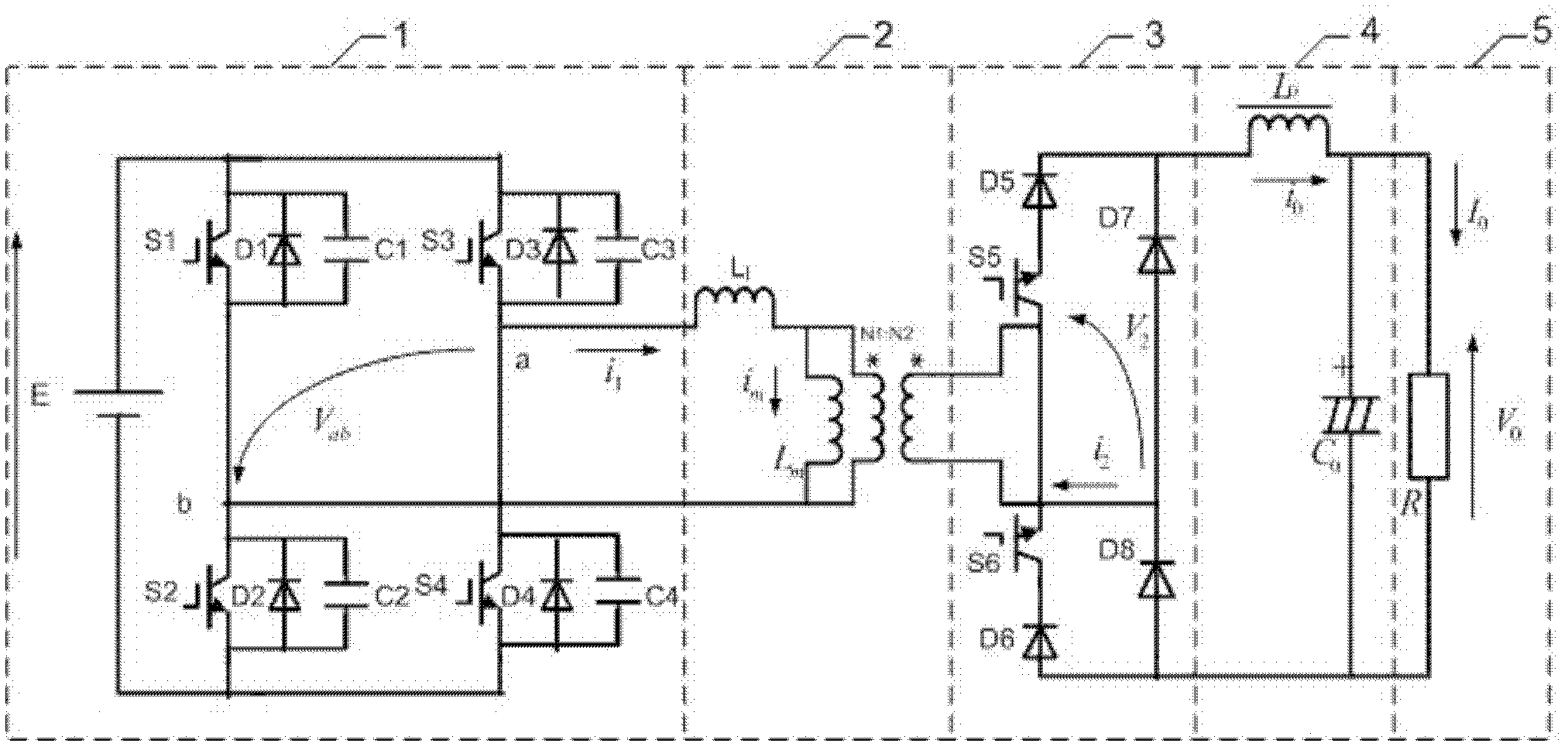

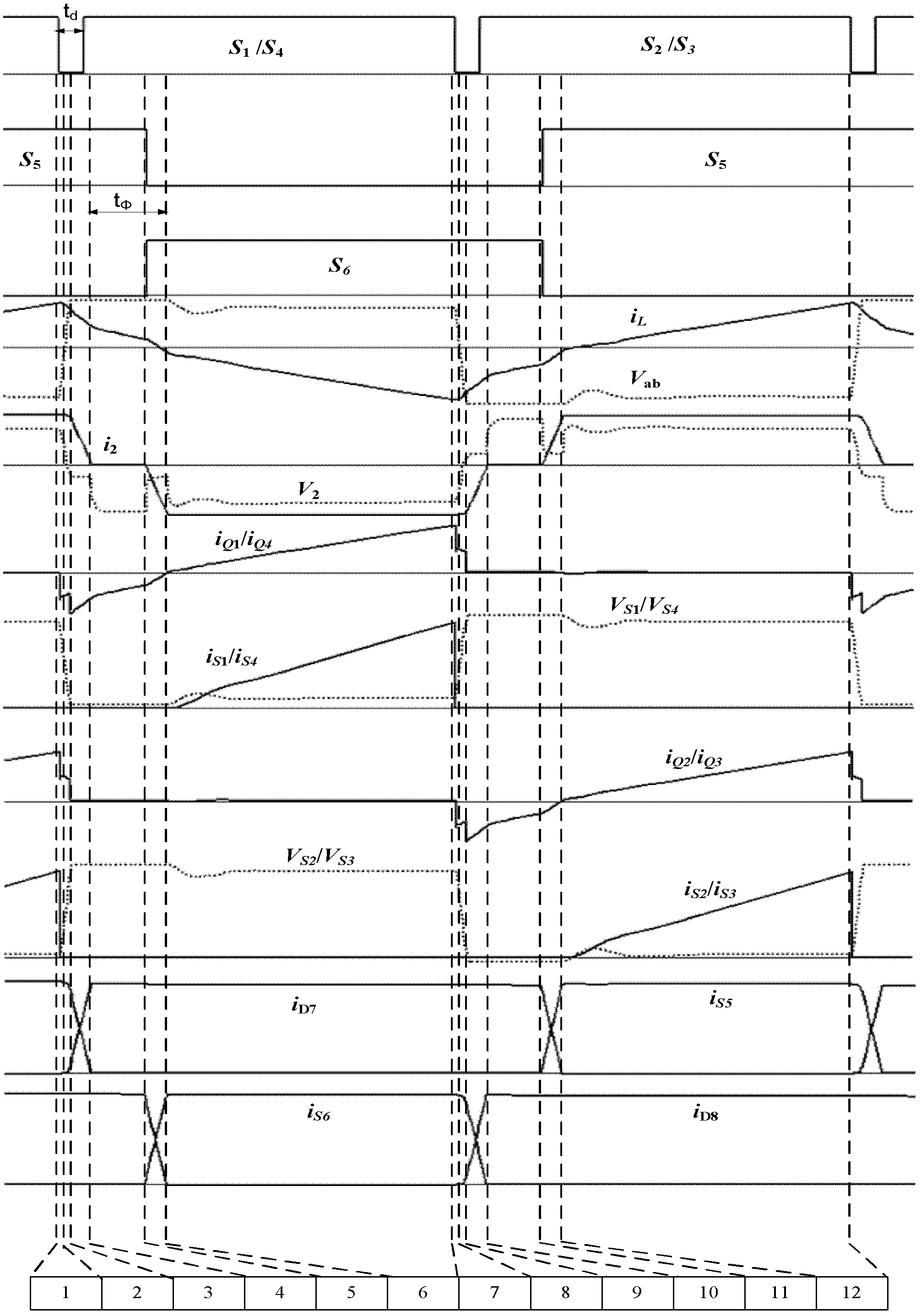

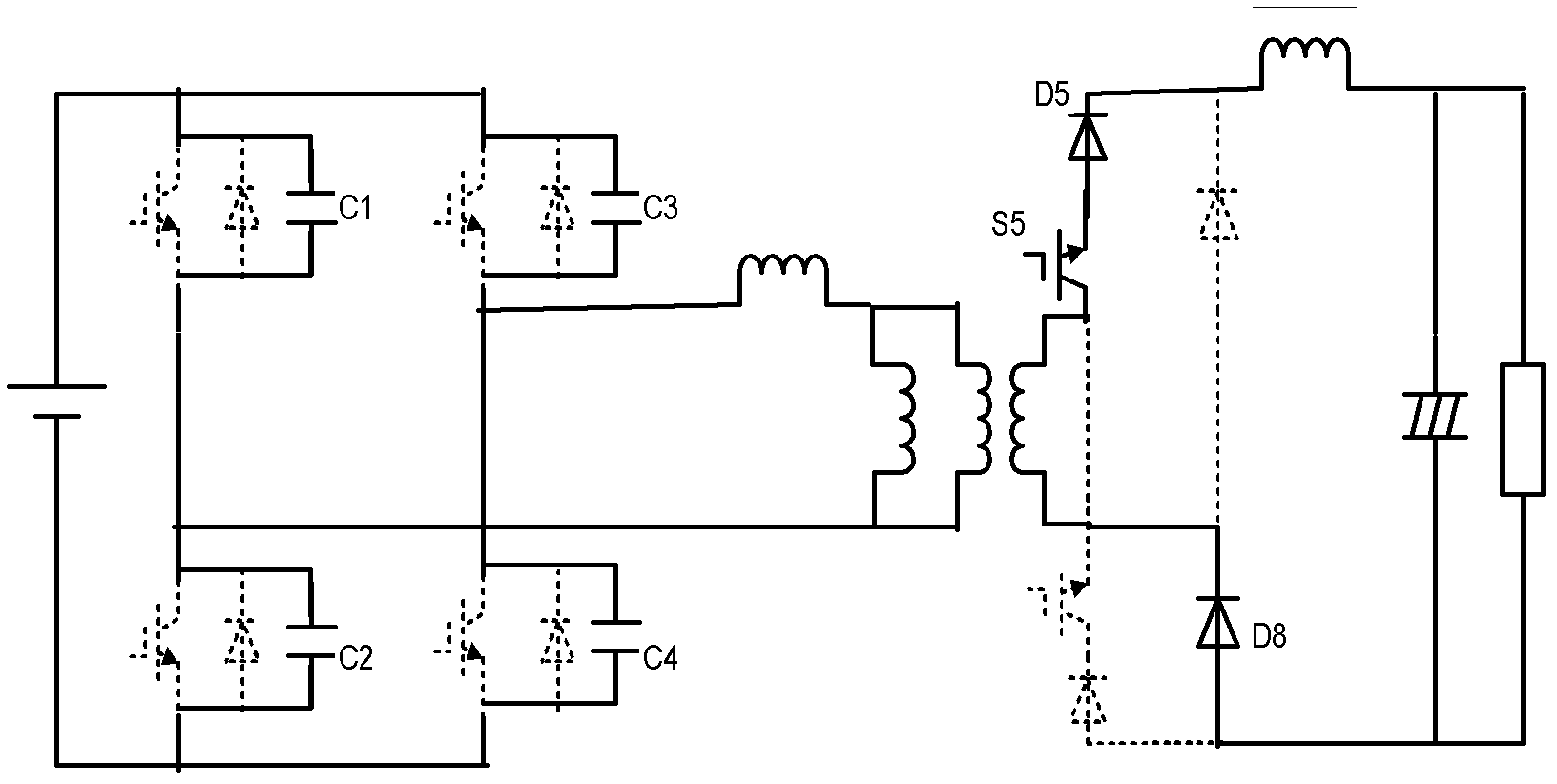

[0017] The present embodiment is similar to the basic full-bridge conversion circuit in that it still consists of an inverter circuit (1), a high-frequency transformer (2), a rectification network (3), a filter circuit (4) and a load (5), Only the rectification network is improved: the fifth switching tube S5 and the sixth switching tube S6 are respectively connected in series at the two output ends of the secondary side of the transformer, as figure 1 As shown, among them, the inverter circuit (1) is composed of four switching tubes S1~S4 connected in series, and the switching tube S 1 The drain of the switch is connected to the positive pole of the DC bus, the source of the switch S1 is connected to the drain of the switch S2, the source of the switch S2 is connected to the source of the switch S4, the drain of the switch S3 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com