Fungus essence and manufacturing method thereof

A production method and the technology of mushroom essence, which are applied in the field of seasoning, can solve the problems of no edible mushroom seasoning, etc., and achieve the effects of rich taste, reduced production cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

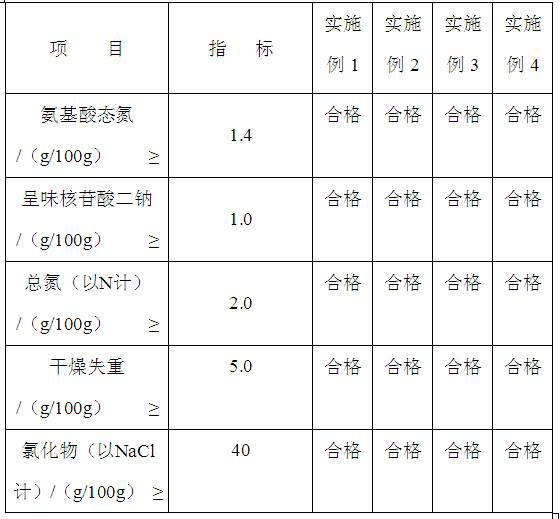

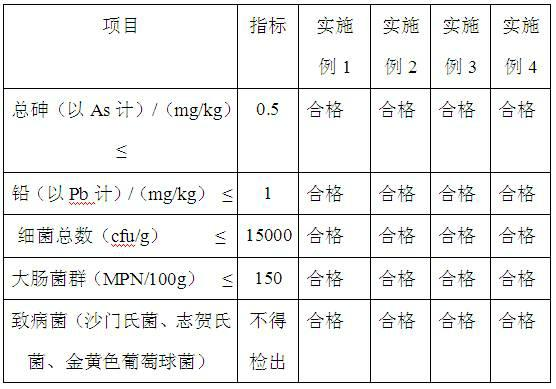

Examples

Embodiment 1

[0069] A mushroom essence, which is composed of the following raw materials in parts by weight: 8 parts of edible fungus mixture, 35 parts of monosodium glutamate, 25 parts of salt, 5 parts of maltodextrin, 6 parts of starch, 6 parts of sugar, 1 part of I+G, and 1 part of yeast essence 1 part, food essence 1 part.

[0070] A method for preparing mushroom essence, comprising the following steps: a. Raw material preparation: weighing the raw materials according to the above weight parts; b. Making edible mushroom mixture: taking 4 parts of shiitake mushrooms, 2.4 parts of Put it into a cooking pot, add an appropriate amount of water, as long as the water just submerges the raw materials, boil the water, and continue to cook for 35 minutes; then take out the raw materials of shiitake mushrooms, matsutake, and oyster mushrooms, crush them and homogenize them with a colloid mill to obtain Edible mushroom mixture; c. Stirring and mixing: adding monosodium glutamate, salt, maltodextr...

Embodiment 2

[0073] A mushroom essence, which is composed of the following raw materials in parts by weight: 12 parts of edible fungus mixture, 38 parts of monosodium glutamate, 30 parts of salt, 5 parts of maltodextrin, 5 parts of starch, 5 parts of sugar, 2 parts of I+G, 2 parts of yeast essence 1 part, food essence 1 part.

[0074] A preparation method of mushroom essence, comprising the following steps: a. Raw material preparation: weighing the raw materials according to the above weight parts; Put it into a cooking pot, add an appropriate amount of water, as long as the water just immerses the raw materials, boil the water, and continue to cook for 38 minutes; then take out the raw materials of shiitake mushrooms, matsutake, and oyster mushrooms, crush them and homogenize them with a colloid mill to obtain Edible mushroom mixture; c. Stirring and mixing: adding monosodium glutamate, salt, maltodextrin, starch, sugar, I+G, yeast essence, and edible flavor to the edible fungus mixture p...

Embodiment 3

[0077] A mushroom essence, which is composed of the following raw materials in parts by weight: 10 parts of edible fungus mixture, 40 parts of monosodium glutamate, 30 parts of salt, 8 parts of maltodextrin, 8 parts of starch, 8 parts of sugar, 5 parts of I+G, yeast essence 5 parts, 2 parts of edible essence.

[0078] A method for preparing mushroom essence, comprising the following steps: a. Raw material preparation: weighing the raw materials according to the above weight parts; b. Making edible fungus mixture: taking 5 parts of shiitake mushrooms, 3 parts of Put it into a cooking pot, add an appropriate amount of water, as long as the water just immerses the raw materials, boil the water, and continue to cook for 36 minutes; then take out the raw materials of shiitake mushrooms, matsutake, and oyster mushrooms, crush them and homogenize them with a colloid mill to obtain Edible mushroom mixture; c. Stirring and mixing: adding monosodium glutamate, salt, maltodextrin, starch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com