Method for producing smaller-flakiness-ratio aluminum alloy slab ingot with adjustable crystallizer

A technology of crystallizer and aluminum alloy, applied in the field of aluminum alloy, can solve the problems of low equipment utilization rate, low comprehensive yield and low production efficiency, and achieve the effect of increasing production capacity, reducing production cost and expanding production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

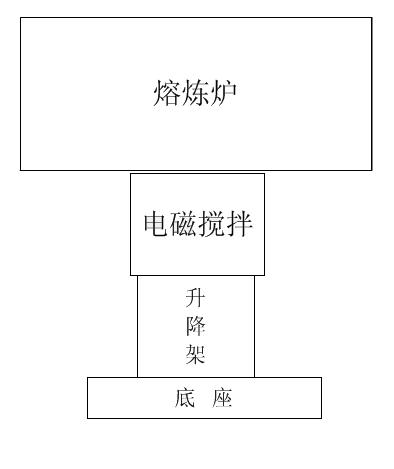

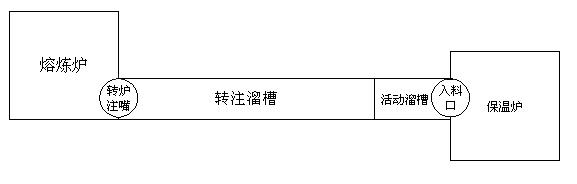

[0053] A casting method for producing a 5052 aluminum alloy flat ingot with a small aspect ratio by using an adjustable crystallizer, comprising electromagnetically stirring the molten aluminum alloy through a 50t smelting furnace, Electromagnetic stirring can be used as long as there is already 50mm deep aluminum liquid. Electromagnetic stirring is introduced from ABB company in Sweden ABB electromagnetic stirrer ORD-30 device, its principle is : The electromagnetic stirrer uses the three-phase alternating current generated by the frequency converter. The low-frequency current in the stirrer coil generates a traveling wave magnetic field, and its carrier frequency can reach 20KHZ. This traveling wave magnetic field penetrates the stainless steel plate and generates stirring force in the aluminum molten pool. Stirring force drives the aluminum liquid, uniform the temperature of the upper and lower surfaces of the aluminum liquid, and promotes the inclusions and gases in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com