Polymeric barrier removal polishing slurry

A technology of slurry and water-based slurry, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, polishing compositions containing abrasives, etc., and can solve problems such as no barrier removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The first set of slurries were characterized by varying BTA, poly(methyl vinyl ether), potassium phosphate and GABA. The polishing data are shown in Table 2 below.

[0048] Table 2

[0049]

[0050]

[0051] CDO is equal to the construction of Novellus' Coral; "high" in the table represents the desired minimum tantalum removal rate.

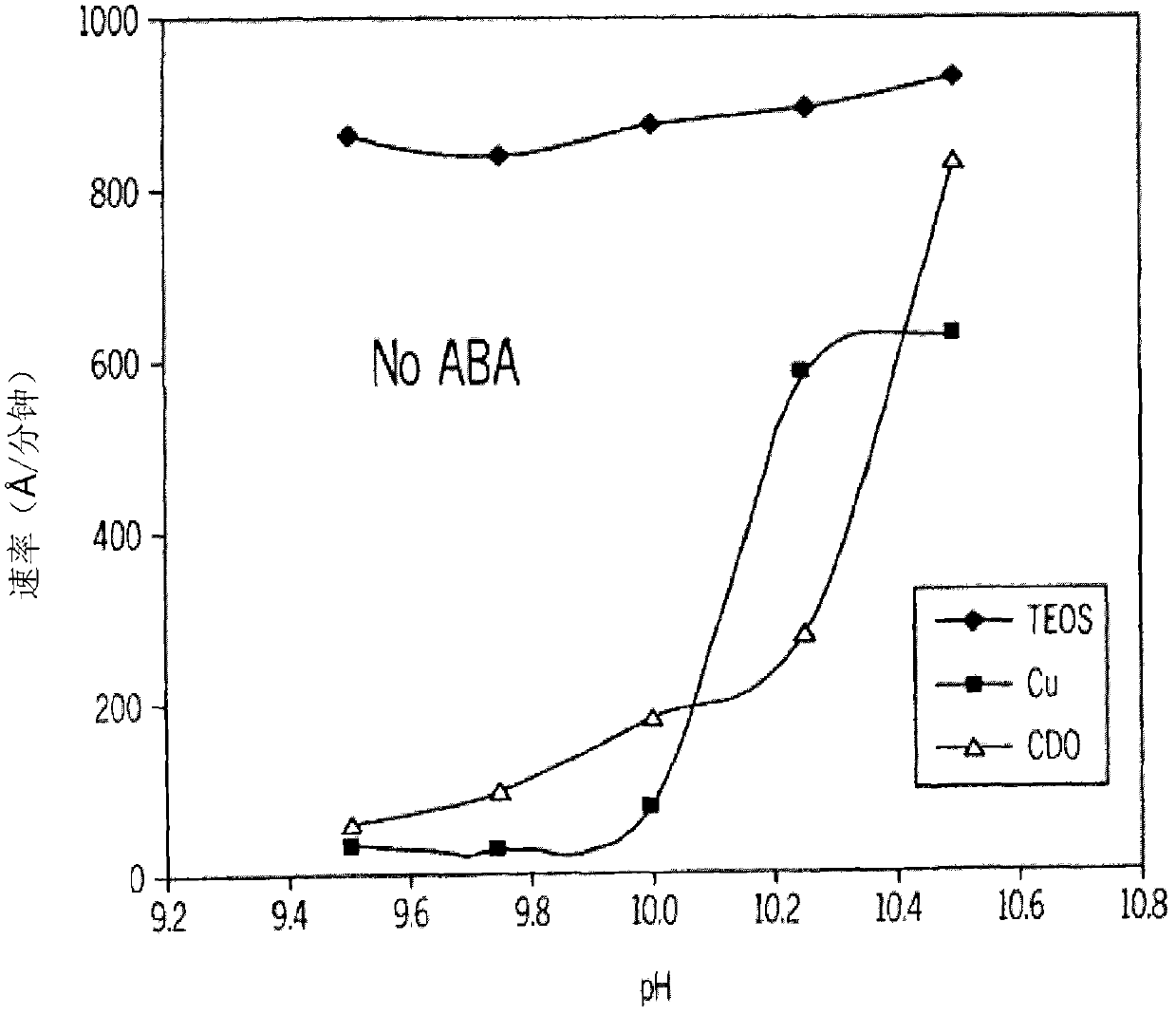

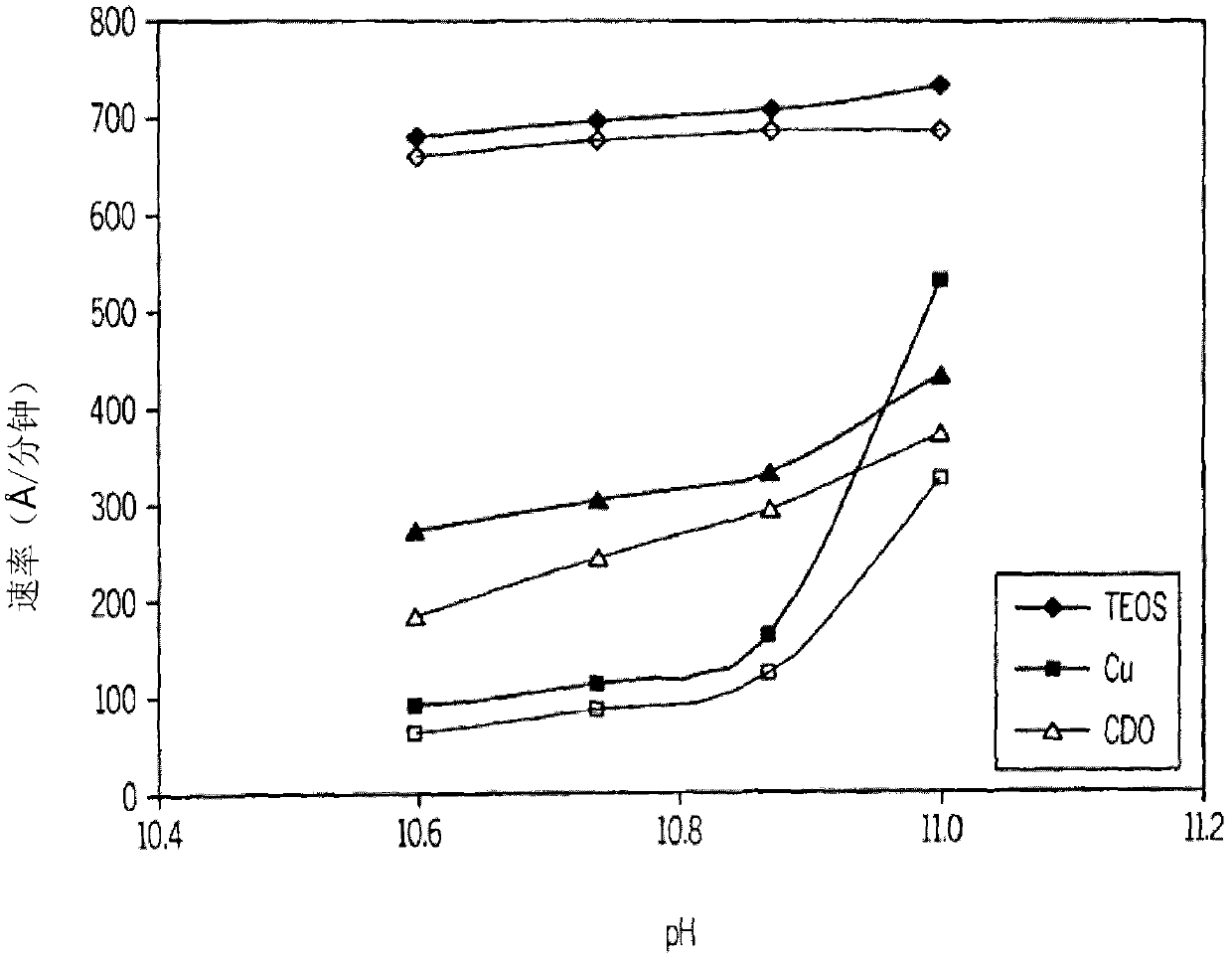

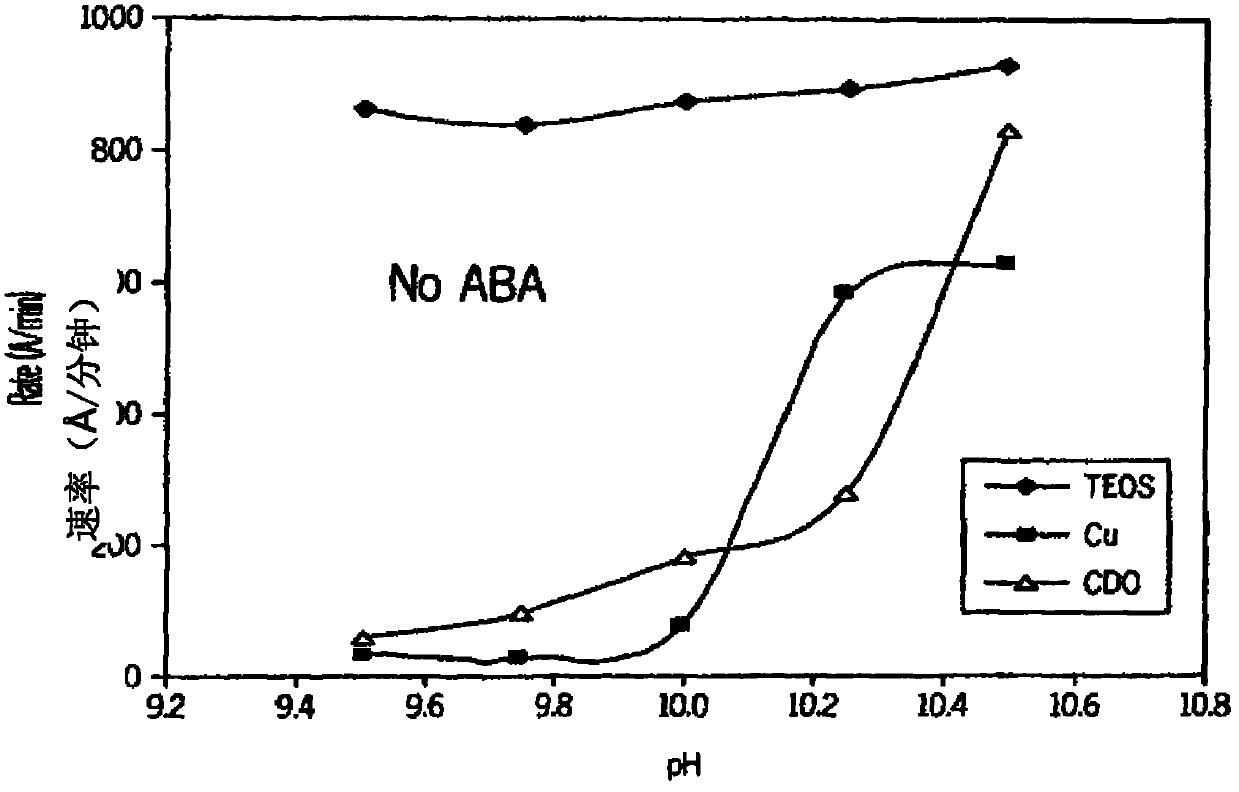

[0052] The above data indicated that varying the concentrations of BTA, poly(methyl vinyl ether), potassium phosphate and GABA had no significant effect on the removal rates of TEOS, CDO and copper. refer to figure 1 with 2 , figure 2 Indicates that the removal rate stability remains consistent with GABA.

Embodiment 2

[0054] The second set of slurries determined polishing characteristics by varying BTA, polymethylvinyl ether, potassium phosphate and GABA. The polishing data are shown in Table 3 below.

[0055] table 3

[0056]

[0057] CDO is equivalent to Coral purchased from Novellus; "High" in the table represents a desired tantalum removal rate of at least

[0058] The above data indicated that varying the concentrations of BTA, poly(methyl vinyl ether), potassium phosphate and GABA had no significant effect on the removal rates of TEOS, CDO and copper.

[0059] Table 2

Embodiment 3

[0061] The third set of slurries determined polishing characteristics for copper and carbon-doped oxides by varying BTA, poly(methyl vinyl ether), potassium phosphate, and GABA, including carbon-doped oxides for patterned wafers. thing. Polishing data are shown in Table 4 below.

[0062] Table 4

[0063]

[0064] CDO is equivalent to Coral available from Novellus; CDO patterned wafer is equivalent to Black Diamond from Applied Materials. "High" in the table represents a desired tantalum removal rate of at least

[0065] The above data show that changing the concentration of BTA, poly(methyl vinyl ether), potassium phosphate and GABA has no significant effect on the removal rate of CDO and copper. Furthermore, the above data demonstrate that varying the concentration of BTA, poly(methyl vinyl ether), potassium phosphate and GABA has no significant effect on the removal rate of CDO on patterned wafers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com