Grouping method of tobacco raw material leaf component

A grouping method and technology of raw materials, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of reduction of sensory difference between modules, reduction of functional characteristics of modules, reduction of richness and diversity, and unfavorable processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] 1. Sampling and sample preparation

[0093] 1. Sampling Three consecutive batches of tobacco leaves of each single grade contained in the silk-making formula leaf group were sampled in the raw material warehouse, and multi-point sampling was performed on tobacco leaves of each grade from different cigarette bales during sampling. The three batches of samples obtained from each grade of tobacco leaves were manually shredded and mixed evenly, and the most representative shredded tobacco samples were screened out by the quartering method;

[0094] 2. Sample preparation

[0095] Put the sample in an oven and dry it at 40°C until it can be crushed by hand (about 5-6% moisture content), and then grind it finely with a FOSS CYCLOTEC 1093 cyclone mill with a 40-mesh screen. After more than 2 minutes, put the smoke powder into a brown bottle for detection;

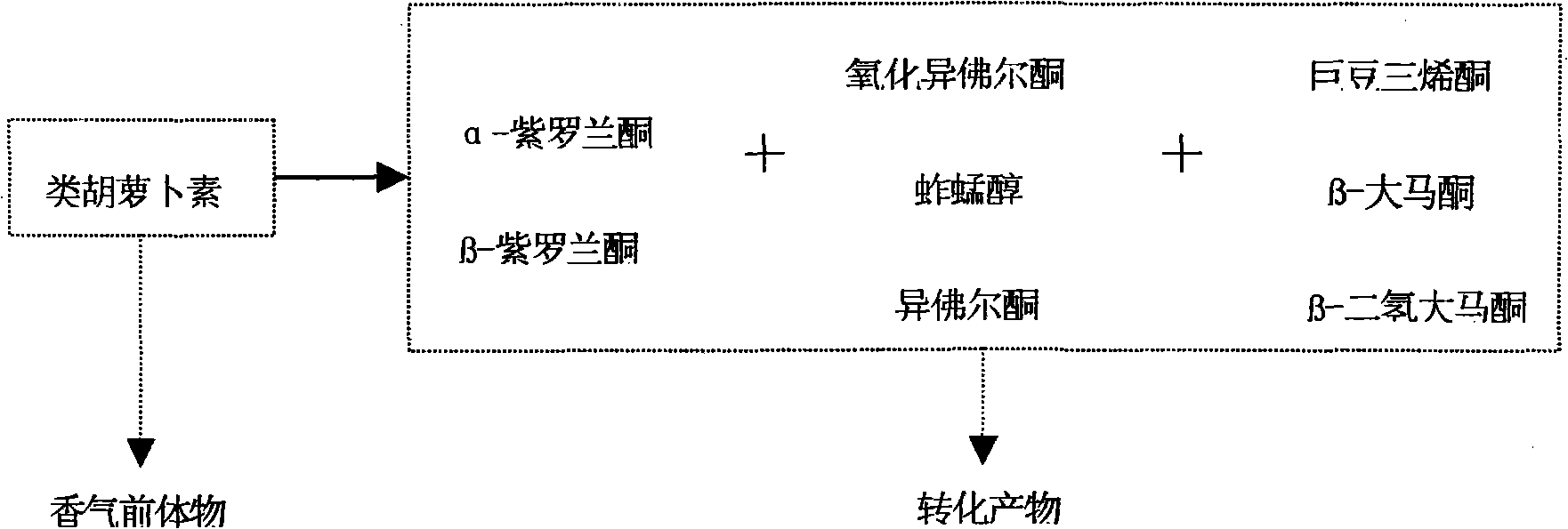

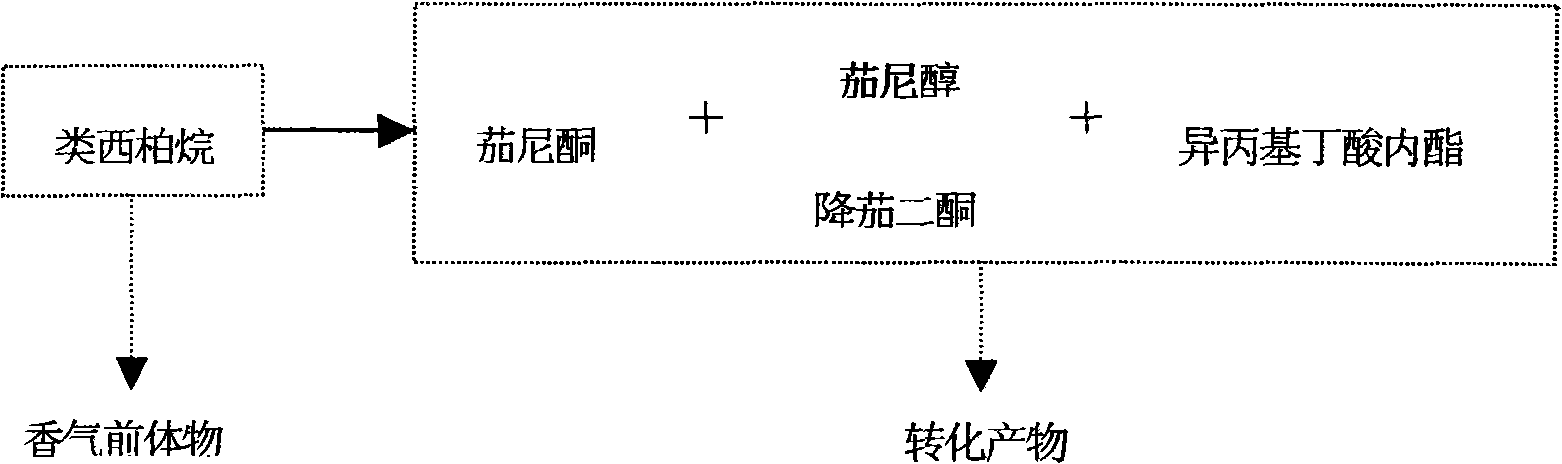

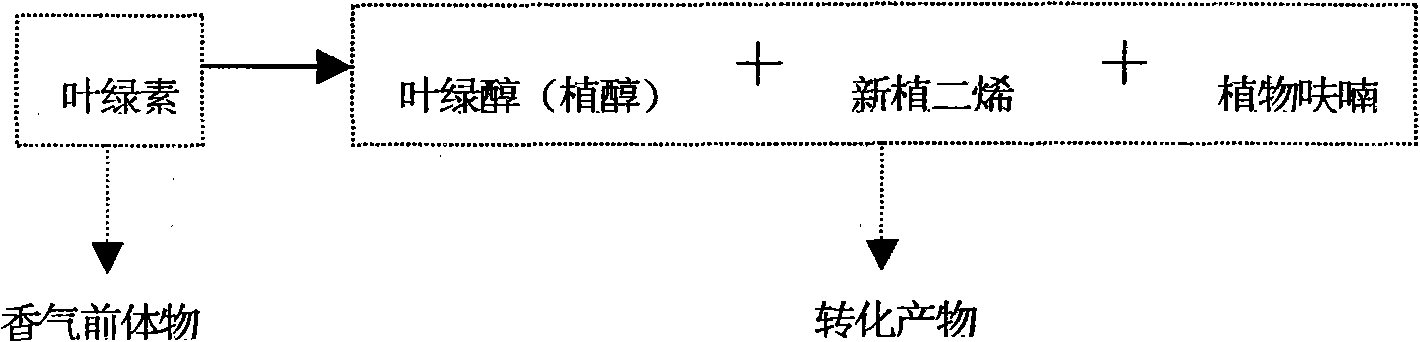

[0096] 2. Detection of aroma components

[0097] (1) Reagents: dichloromethane (redistilled), anhydrous sodium sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com