External activation method of benzene oxidation to maleic anhydride catalyst

An activation method and catalyst technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as increased input costs, and achieve cost savings, performance improvements, and increased activation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

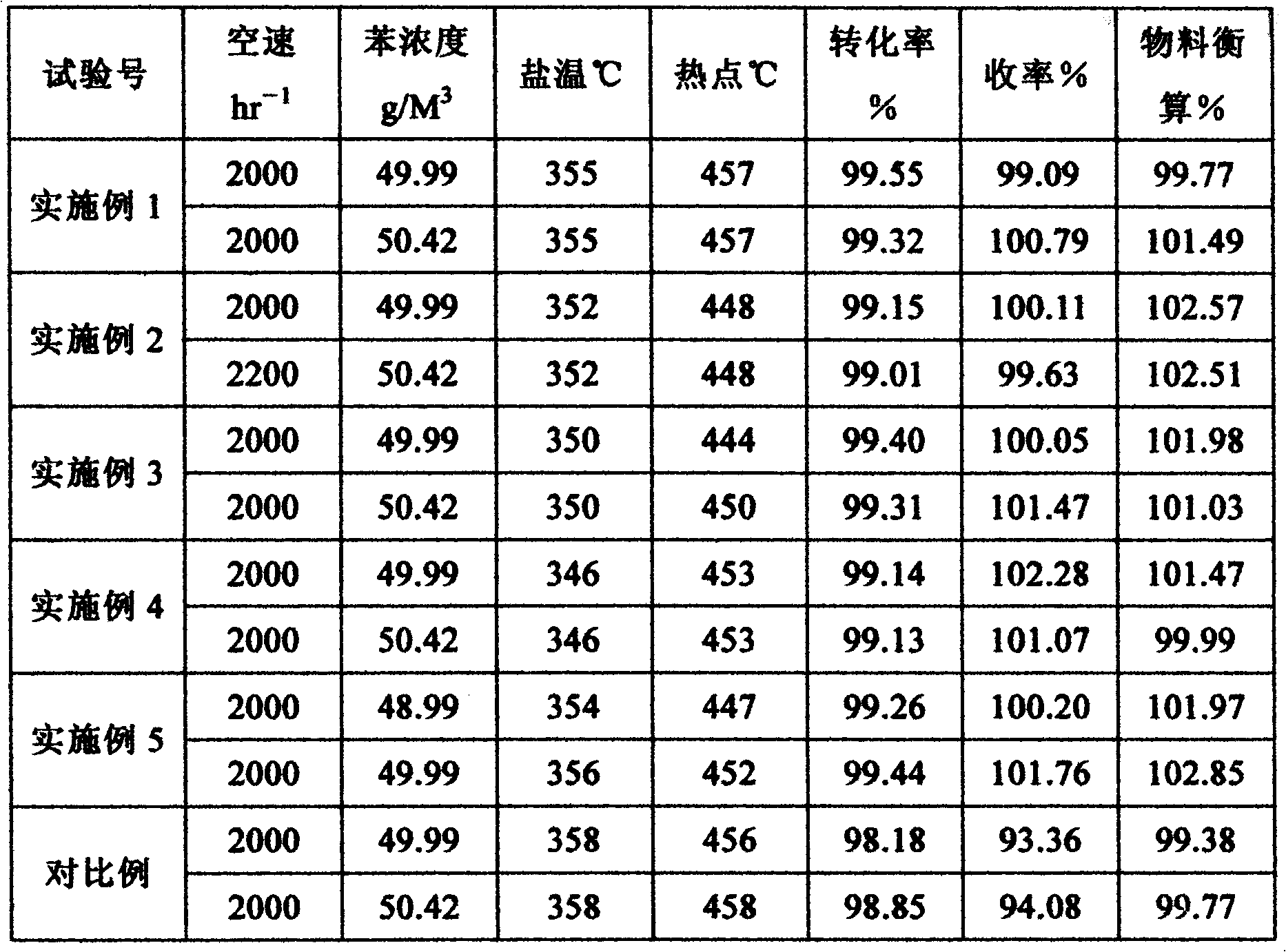

Embodiment 1

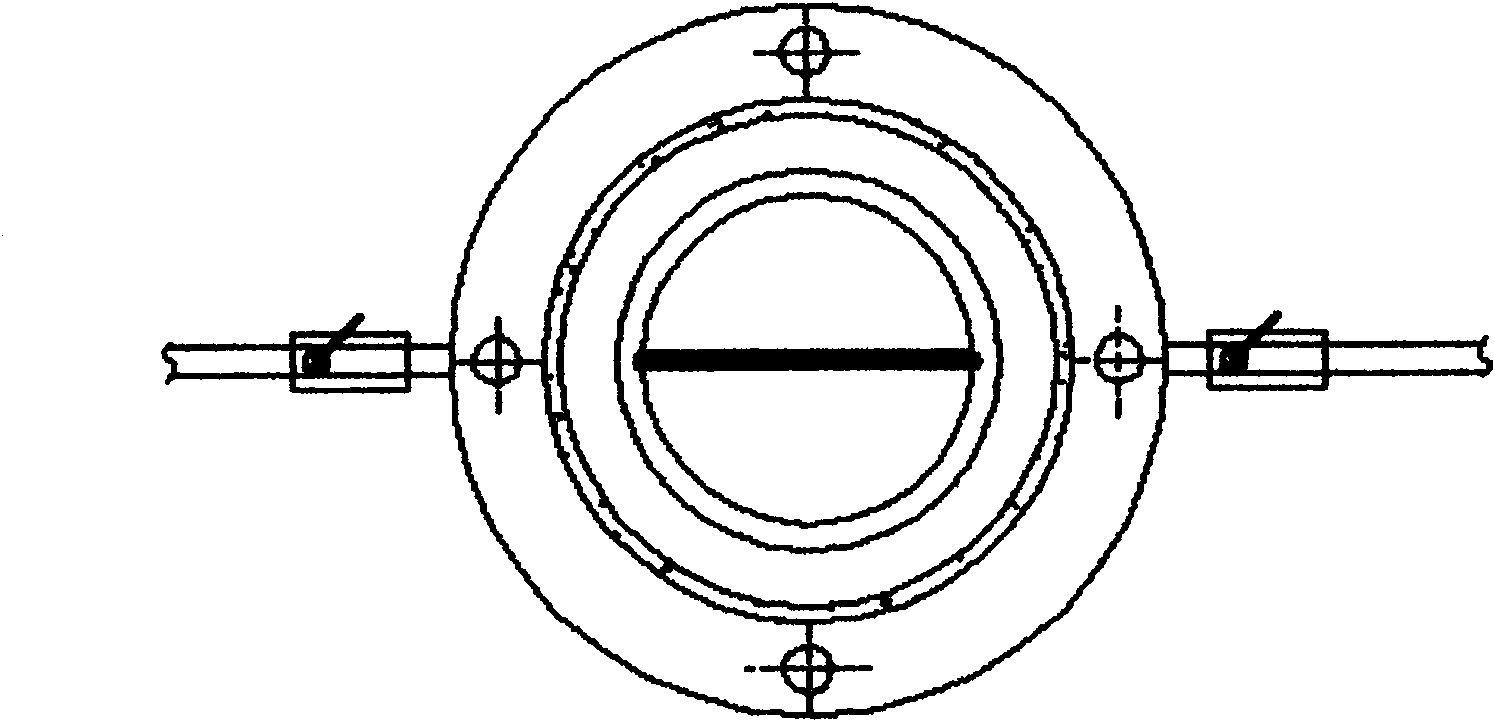

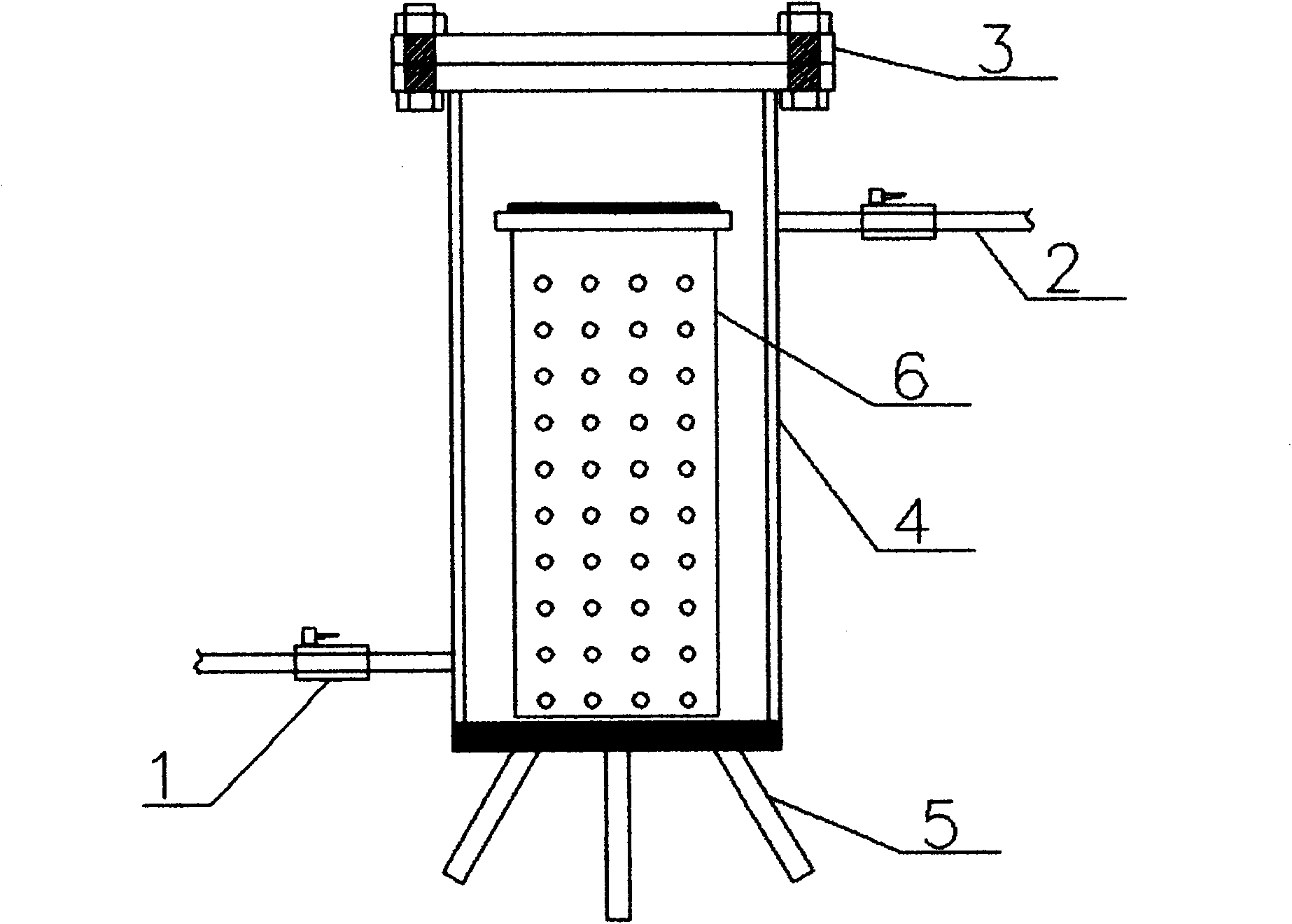

[0024] Measure 150ml of maleic anhydride catalyst by benzene oxidation, put it into the cylindrical liner 6 of the activation furnace, seal the top cover flange 3, and close the air inlet 1 at one end of the activator. Raise the temperature at 50°C per hour to 300°C. After reaching the temperature, continue to raise the temperature at 25°C per hour until the temperature rises to 450°C and keep it warm for 4 hours. Cool down to room temperature naturally, and cut off the power supply. Afterwards, take out the catalyst after activation, load on the 120ml evaluation device, at a space velocity of 2000hr -1 , Benzene concentration 48~54g / M 3 conditions are evaluated.

Embodiment 2

[0026] Measure 260 ml of maleic anhydride series catalysts by benzene oxidation, put them into the cylindrical liner 6 of the activation furnace, seal the top cover flange 3, and close the air inlet 1 at one end of the activator. Raise the temperature at 50°C per hour to 300°C. After reaching the temperature, continue to raise the temperature at 25°C per hour until the temperature rises to 450°C and keep the temperature for 6 hours. Cool down to room temperature naturally, and cut off the power supply. Afterwards, with embodiment 1.

Embodiment 3

[0028] Measure 180 ml of maleic anhydride series catalysts by benzene oxidation, put them into the cylindrical liner 6 of the activation furnace, seal the top cover flange 3, and close the air inlet 1 at one end of the activator. Raise the temperature at 50°C per hour to 310°C. After reaching the temperature, continue to raise the temperature at 25°C per hour until the temperature rises to 460°C and keep the temperature for 5 hours. Cool down to room temperature naturally, and cut off the power supply. Afterwards, with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com