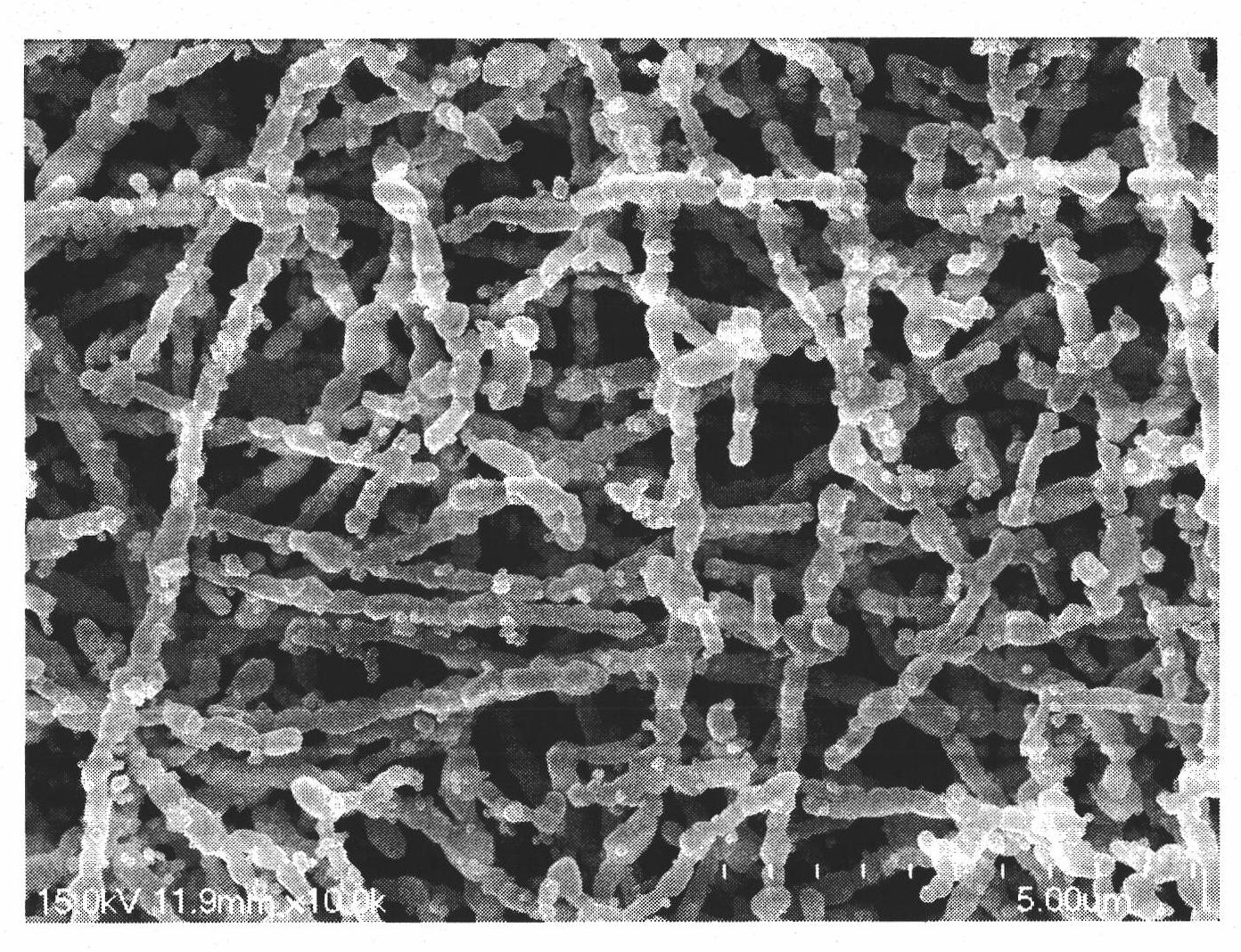

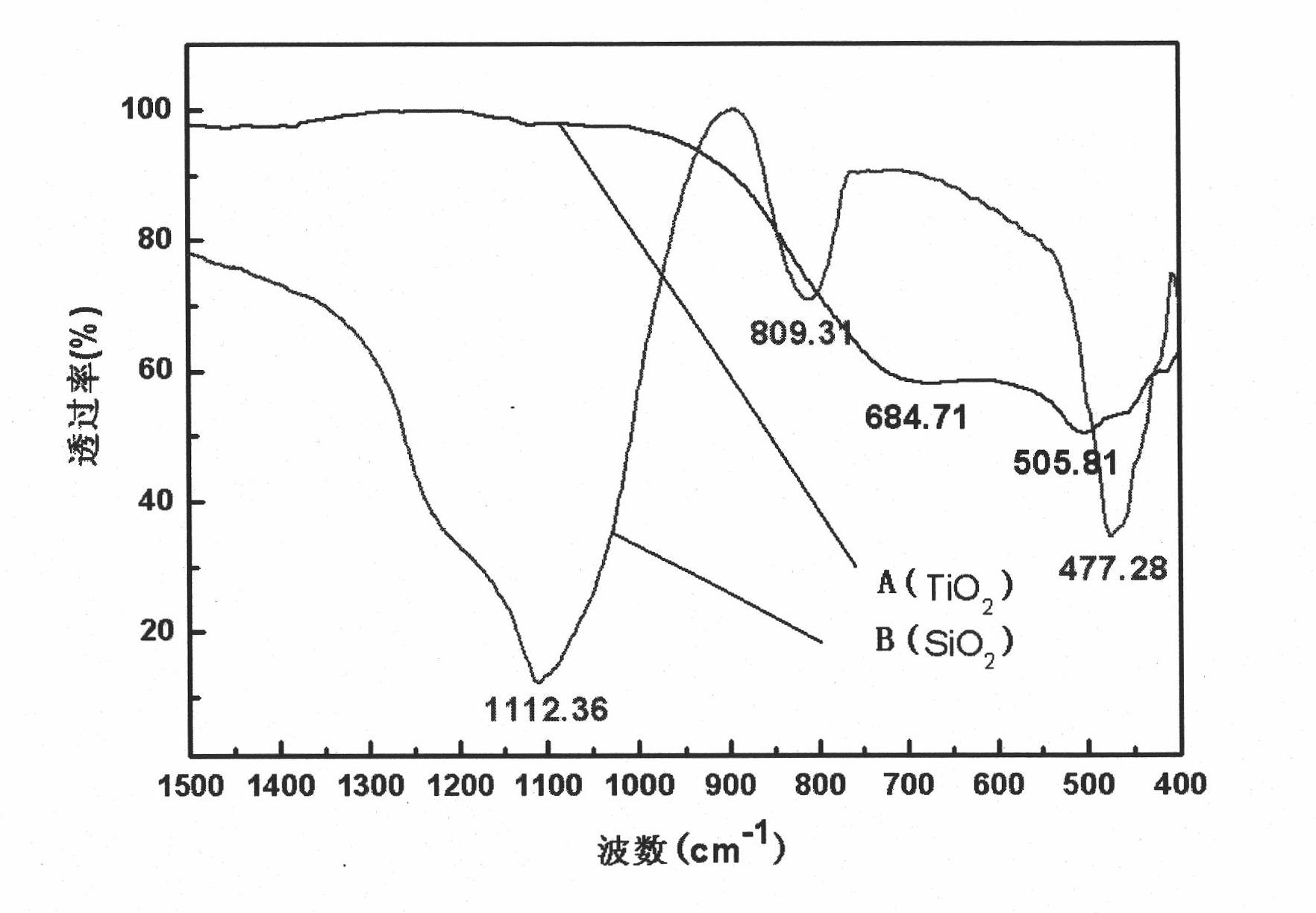

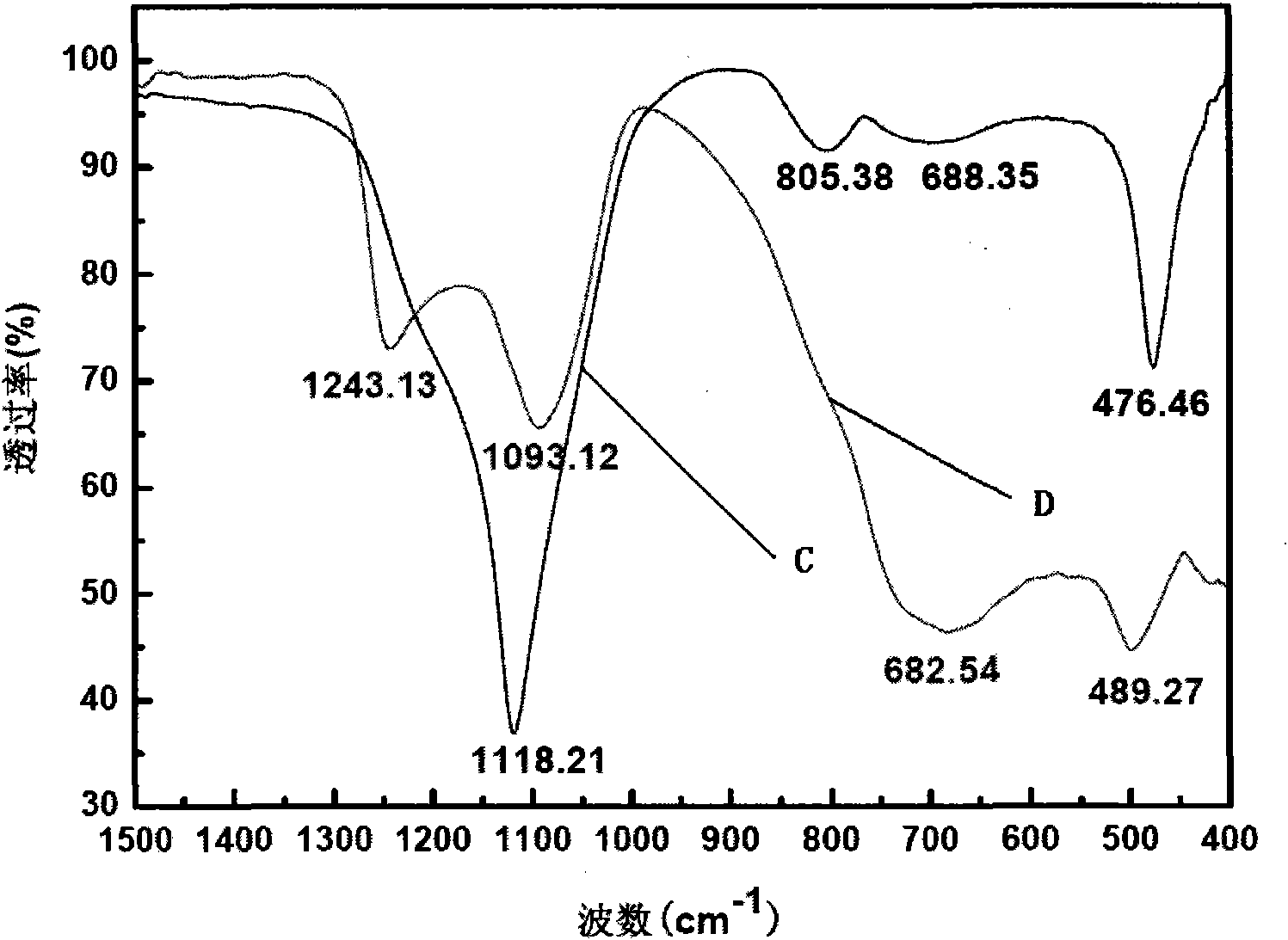

TiO2-SiO2 bi-component nano-grade fiber and preparation method thereof

A nanofiber, two-component technology, applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of difficult to obtain nanofibers, cannot fully reflect the advantages of two-component nanocomposite fibers, etc. Wide-ranging, easy-to-control, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] By weight, under stirring conditions, 0.6g of polyvinylpyrrolidone, 10.0g of absolute ethanol, 4.0g of butyl titanate and 4.0g of concentrated HCl were added to a 100ml round bottom flask at a temperature of 75°C Under the conditions of constant temperature reaction for 2 hours, solution A was obtained;

[0039] The solution A was subjected to electrospinning, the voltage used for electrospinning was 15 kV, the injection rate was 2 ml / hour, the curing distance was 8 cm, the receiving device was aluminum foil, and the electrospinning time was 2 hours, the corresponding Nanofibers;

[0040] The nanofibers obtained by electrospinning were dried at a temperature of 100°C for 12 hours, then heated to 650°C at a heating rate of 1°C / min, and kept at a constant temperature for 4 hours to obtain a preliminary product;

[0041] By weight, 6.0 g of concentrated ammonia water was added dropwise to 100.0 g of absolute ethanol under stirring conditions, and after stirring for 4 hour...

Embodiment 2

[0046] 1) By weight, under stirring conditions, mix 0.6g of polyvinylpyrrolidone, 15.0g of absolute ethanol, 4.0g of butyl titanate and 4.0g of concentrated H 2 SO 4 Add it into a 100ml round bottom flask, and react at a constant temperature of 90°C for 6 hours to obtain solution A;

[0047] 2) The solution A was subjected to electrospinning, the voltage used for electrospinning was 15 kV, the sampling rate was 1 ml / hour, the curing distance was 15 cm, the receiving device was aluminum foil, and the electrospinning time was 3 hours, the obtained corresponding nanofibers;

[0048] 3) drying the nanofibers obtained by electrospinning at a temperature of 85°C for 24 hours, then heating to 500°C at a heating rate of 1°C / min, and keeping the temperature constant for 8 hours to obtain a preliminary product;

[0049] 4) Add 10.0 g of concentrated ammonia water dropwise to 150.0 g of absolute ethanol by weight under stirring conditions, and after stirring for 2 hours, add 5.0 g of e...

Embodiment 3

[0053] 1) By weight, under agitation, 0.6g of polyvinylpyrrolidone, 12.0g of dehydrated alcohol, 4.0g of butyl titanate and 4.0g of p-toluenesulfonic acid were added to a 100ml round bottom flask, Under the temperature condition of 20°C, the reaction was carried out at constant temperature for 8 hours to obtain solution A;

[0054] 2) The solution A was subjected to electrospinning, the voltage used for electrospinning was 20 kV, the injection rate was 8 ml / hour, the curing distance was 12 cm, the receiving device was aluminum foil, and the electrospinning time was 2 hours, and the obtained corresponding nanofibers;

[0055] 3) drying the nanofibers obtained by electrospinning at a temperature of 70°C for 24 hours, then heating to 1100°C at a heating rate of 1°C / min, and keeping the temperature constant for 4 hours to obtain a preliminary product;

[0056] 4) Add 4.0 g of concentrated ammonia water dropwise to 120.0 g of absolute ethanol by weight under stirring conditions, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com