High-temperature tail-gas heat-recovering energy-saving device

A heat recovery and energy-saving device technology, applied in the energy industry, climate sustainability, lighting and heating equipment, etc., can solve the problem of small contact area between flue gas and water, and achieve heat pollution avoidance, energy-saving structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

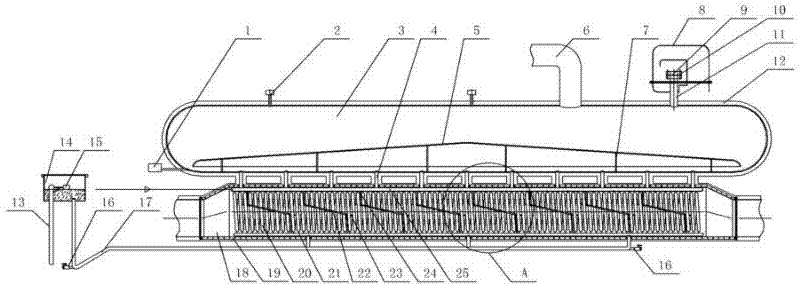

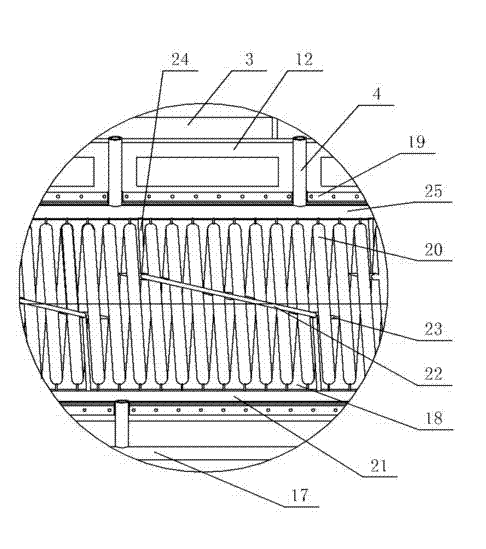

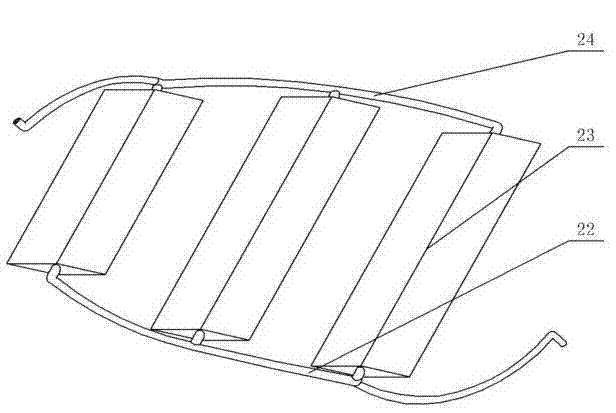

[0018] Such as figure 1 As shown, the present invention is a heat recovery energy-saving device for the high-temperature exhaust gas, which includes a flue 18 connected to the exhaust pipe, the flue 18 is tubular, and the high-temperature tail gas produced by the industrial boiler enters the flue through the exhaust pipe 18 in. The upper end of the air inlet of the flue 18 gradually rises from the outside to the inside, and the upper end of the air outlet of the flue 18 gradually lowers from the inside to the outside, so that the high-temperature exhaust gas can be buffered to a certain extent. The flue 18 includes a left half-shell and a right half-shell, and the left half-shell and the right half-shell are respectively provided with opposite flanges 19, which are fixed with bolts and nuts after the flanges 19 are docked. , the assembly of the flue 18 is completed. The bottom of the inner side of the flue 18 is axially equipped with an inlet water distribution pipe 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com