Low volatile coal water slurry combustion device

A combustion device, low volatile technology, applied in the direction of using a variety of fuel combustion, burners, combustion methods, etc., to achieve the effects of high cost performance, simple equipment structure, easy maintenance and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

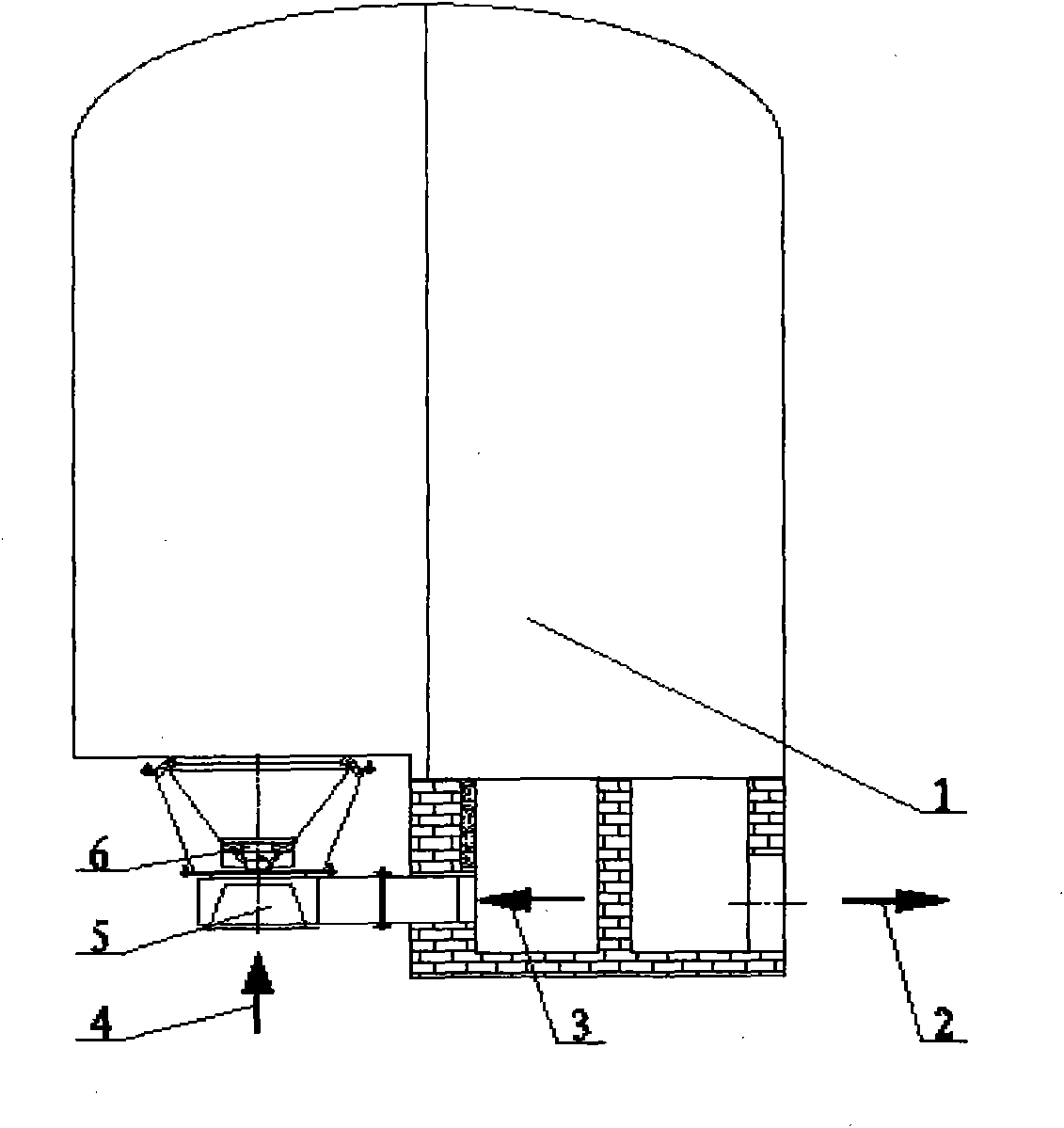

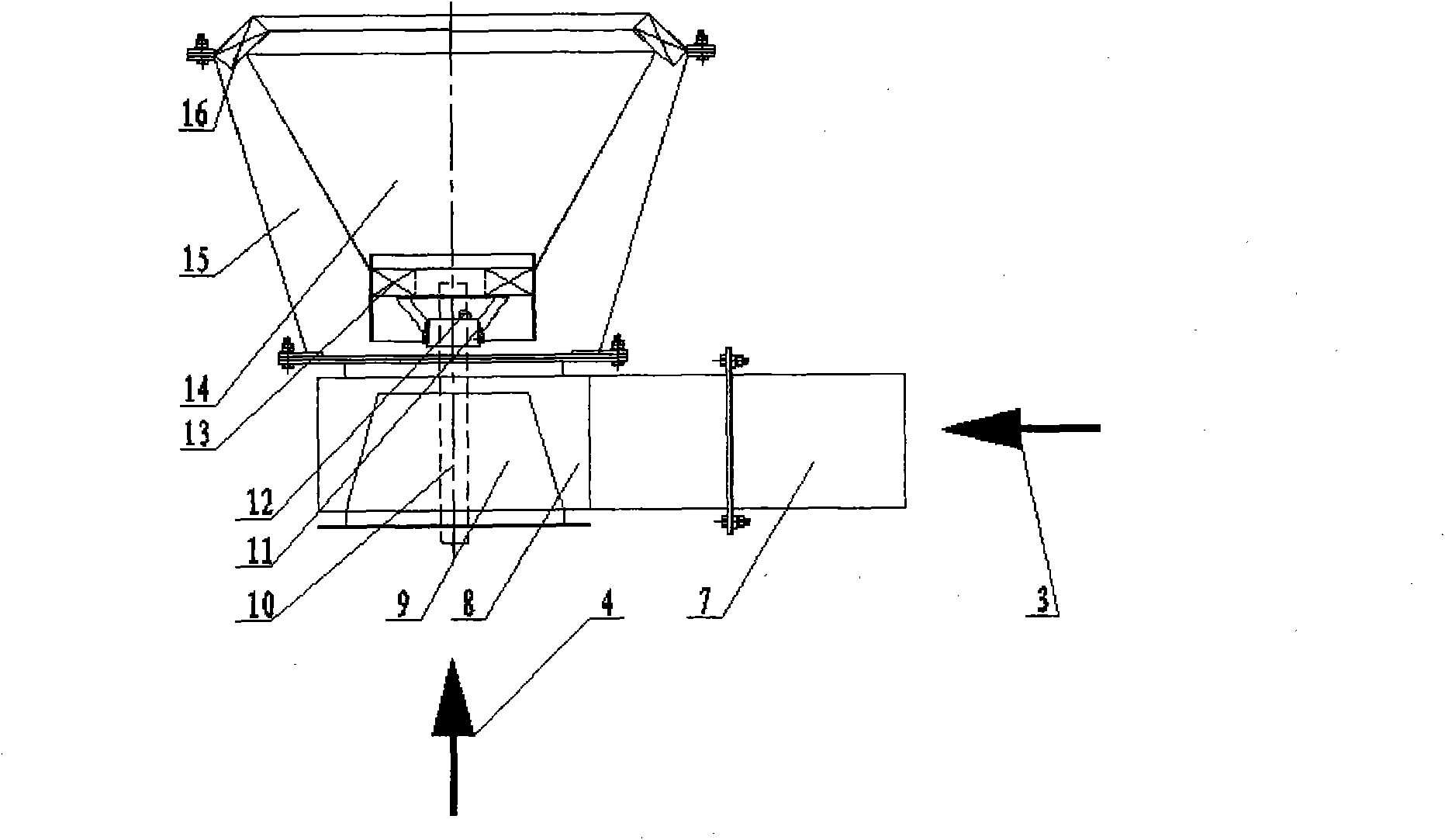

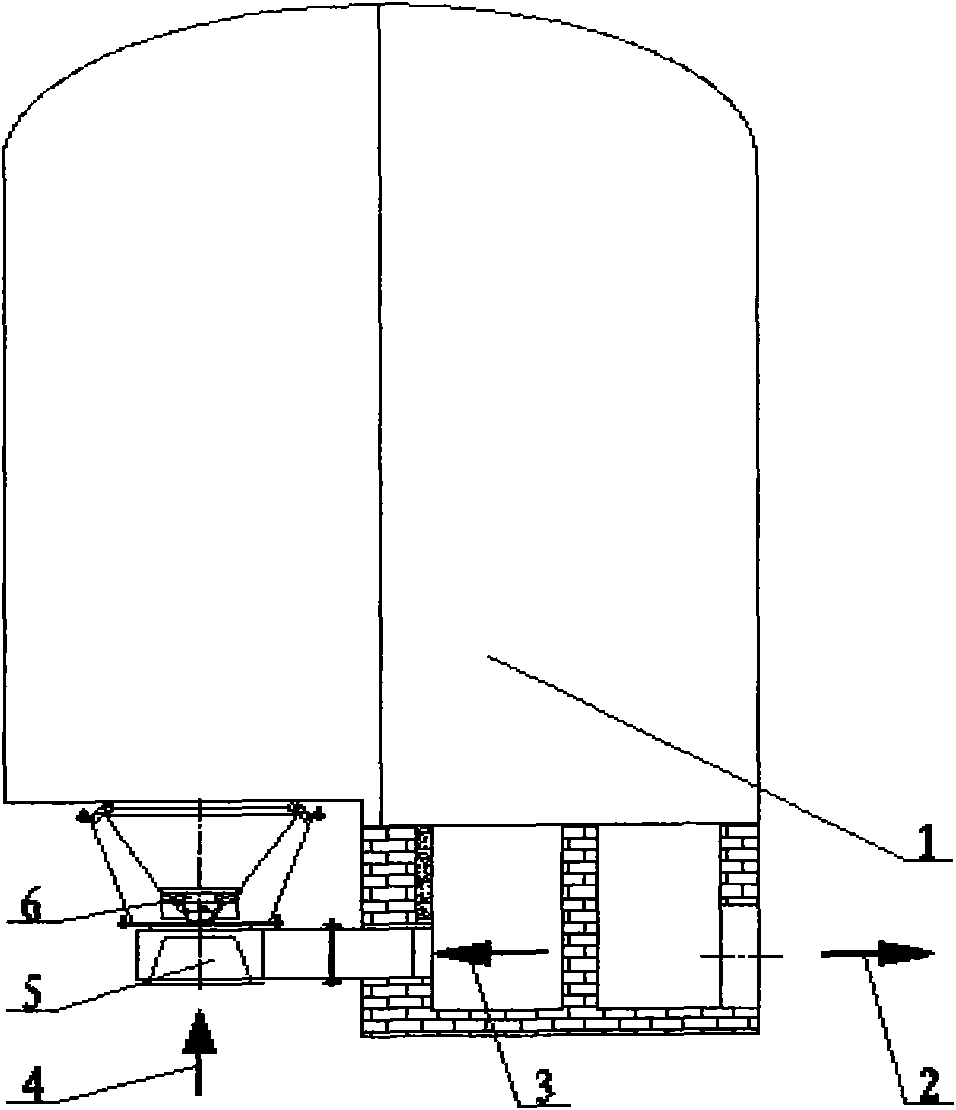

[0022] Depend on figure 1 with figure 2 As shown, a low-volatile coal-water slurry combustion device of the present invention is mainly composed of a back-type combustion chamber 1, an ejector 5, a burner 6, and the like. Wherein the burner 6 comprises a primary swirler 13, a primary combustion chamber 14, a secondary swirler 16, a fuel nozzle (ignition) device 12, a coal-water slurry spray gun 10, a nozzle fixing bracket 11 and a burner mixing chamber 15; The injector 5 includes a high-temperature return gas pipe 7, an injector mixing chamber 8, and an injector inlet nozzle 9; the return-type combustion chamber 1 is a general-purpose return-type industrial furnace structure.

[0023] The ejector inlet nozzle 9 is a convergent structure, its inlet end is directly connected to the high-pressure fan interface or the outlet of the high-pressure air flow pipeline, and its nozzle exhaust port is installed in the center of the ejector mixing chamber 8, And on the same axis; the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com