Control method for voltage-source-type unit power factor high-temperature superconducting energy storage converter

A technology of unit power factor and voltage source type, applied in the direction of DC power input conversion to DC power output, AC power input conversion to DC power output, output power conversion device, etc., can solve the problem of debugging difficulties, complex control circuits, Superconducting magnetic energy storage converter control method is difficult and other problems, to achieve the effect of strong control and signal processing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

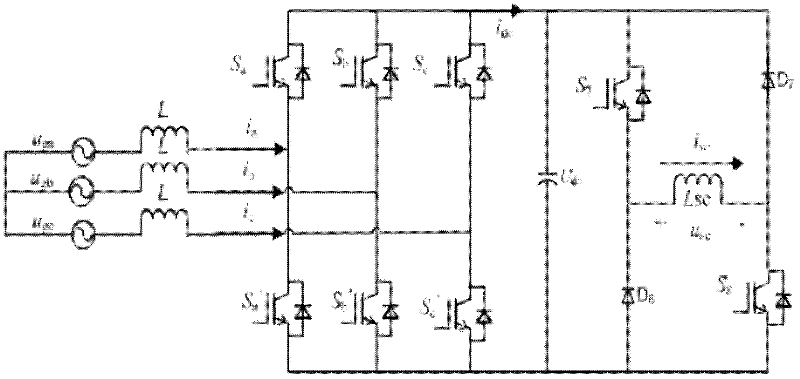

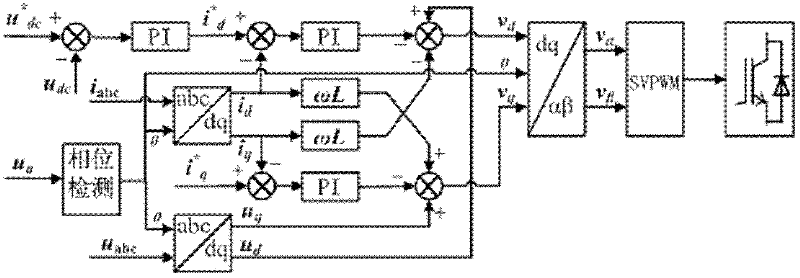

[0064] The circuit topology of the voltage source SMES converter is shown in the attached figure 1 As shown, it includes a four-quadrant three-phase fully-controlled voltage-type converter (VSC) and an "H" type bidirectional DC-DC chopper, and the two are connected with a DC capacitor. Therefore, the mathematical model of the voltage-type SMES can be simplified into two mathematical models: the mathematical model of the voltage-source converter and the mathematical model of the bidirectional chopper.

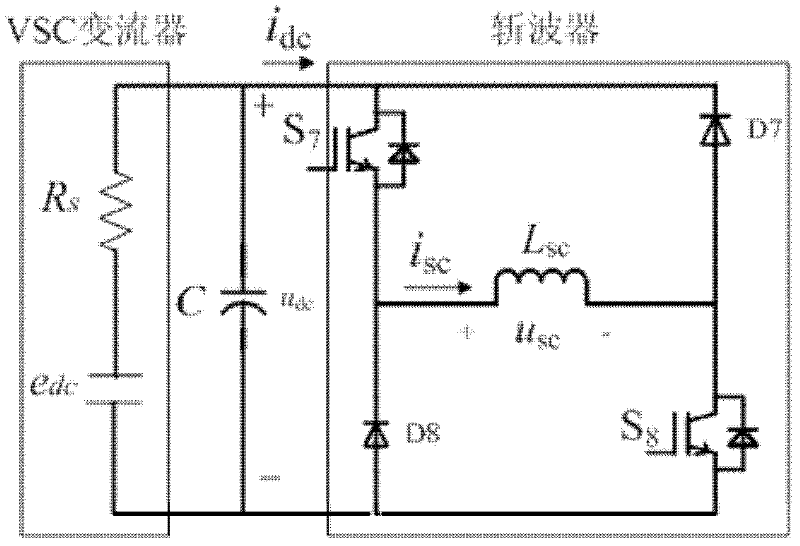

[0065] In the modeling process of the system, the VSC module can be approximately equivalent to a voltage source, therefore, the main circuit of the SMES converter is equivalent to the attached figure 2 . e dc is the equivalent voltage source on the DC side, R s is the internal resistance of the equivalent voltage source, i sc is the superconducting magnet current, i dc is the DC side current of the voltage source converter, u dc is the terminal voltage of DC bus capacito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com